One of the most common complaints about Tesla vehicles has been inconsistent fit and finish, specifically abnormally large or irregular gaps between body panels. Now the company has applied for a patent on a new clamping system that it hopes will eliminate the issue once and for all.

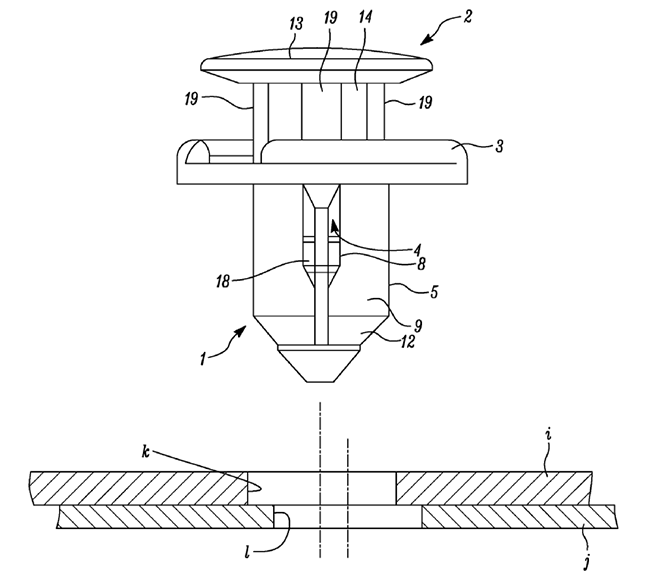

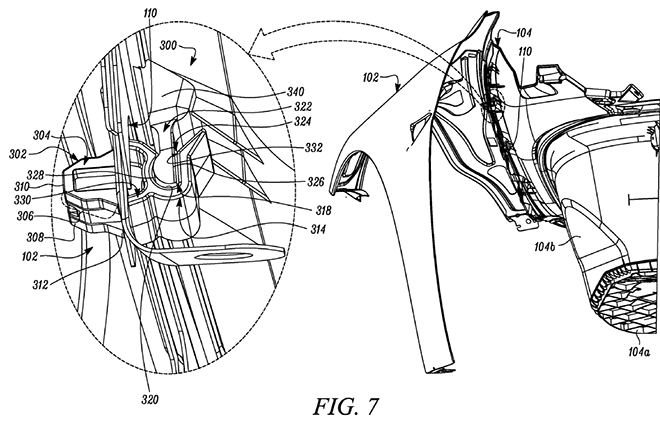

Tesla explains in its patent application (via Electrek) that, for some parts, “it is desirable to allow one or more degrees of freedom in movement between parts to allow for securing in a desirable way that increase the aesthetic appearance of the final assembly.”

“For instance, the clamping of an electric vehicle’s front-trunk space (or ‘frunk’) formed from a plastic, to a fender or another adjacently located panel requires a degree of freedom to allow the panel and the frunk to move relative to one another in at least one direction during assembly. However, traditional designs of clamps are not well suited to this or similar applications.”

Tesla’s clamping system apparently allows panels to be linked together while leaving some room for adjustment. Tesla hasn’t said whether it is already using the new clamping method, but Electrek notes that the panel gap issues that plagued early Model 3 production seem to have been fixed. The photos of yawning, crooked panel gaps that were once a common sight on Reddit and other online hangouts have mostly disappeared. In April, Tesla said that it had made major progress on the panel gap issue.

“Since we began shipping Model 3 last year, we have been very focused on refining and tuning both part and body manufacturing processes. The result being that the standard deviation of all gaps and offsets across the entire car has improved, on average, by nearly 40%, with particular gap improvements visible in the area of the trunk, rear lamps and rear quarter panel. Today, Model 3 panel gaps are competitive with Audi, BMW, and Mercedes models, but in the spirit of relentless improvement, we are working to make them even tighter.”

Source: Electrek