Thermal paste is essential for preventing overheating and short circuits during battery operation. Unfortunately, its application is one of the slowest processes in battery pack production, as potting material is highly viscous and abrasive.

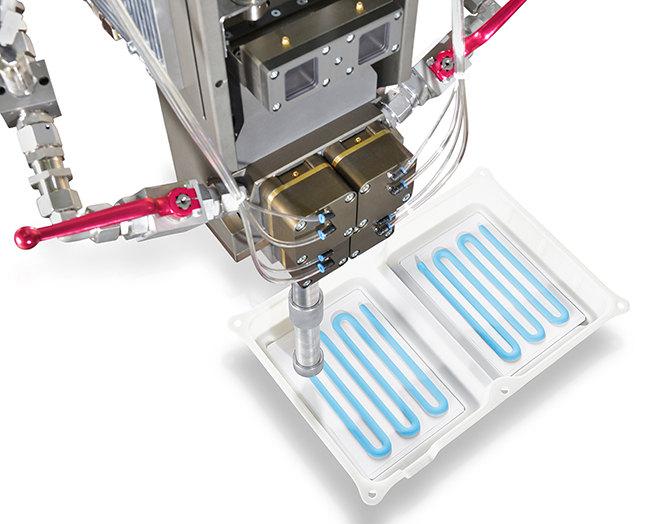

Scheugenpflug, a provider of adhesive bonding, dispensing and potting solutions, has developed a new dispensing solution for thermal potting material that is designed to solve this problem. The company has tackled several interesting dispensing issues in the past, including thermal adhesive dispensing for Alta Motors’ electric dirt bikes.

The new dispensing solution can apply potting material at rates of up to 80 ml per second with delivery pressures of 65 bar for highly viscous materials. These speeds are made possible by a combination of Scheugenpflug’s Dos HP dispenser and its PailFeed200 Abrasive material feeding unit.

The system can apply conducting media with viscosities of up to 1,000,000 mPa∙s and has a maximum volume-per-shot of 310 ml. A 480 cm3 per stroke integrated double-piston pump makes continuous material feed possible. Scheugenpflug claims the system will offer a longer lifespan as well as cheaper, faster and simpler maintenance.

Source: Scheugenpflug