Nexperia has announced a series of half-bridge (high-side and low-side) automotive MOSFETs constructed in the space-saving LFPAK56D package format. The half-bridge configuration of two MOSFETS is a standard building block for many automotive applications, including motor drives and DC/DC converters.

The new package provides a half-bridge solution in one device, and occupies a 30% smaller PCB area compared to dual MOSFETs for 3-phase motor control topologies, due to the removal of PCB tracks, while permitting automated optical inspection (AOI) during production. The LFPAK56D half-bridge employs existing high-volume LFPAK56D assembly processes. The package format uses flexible leads to improve overall reliability, and an internal copper clip connection between the MOSFETs simplifies PCB designs and brings a plug-and-play-style solution with a current handling capability of 98 A.

Typically, in a half-bridge arrangement, the PCB connection between the source of the high-side MOSFET and the drain of the low-side MOSFET can create a significant amount of parasitic inductance. However, with its internal clip connection, the LFPAK56D half-bridge package achieves 60% less inductance.

The new LFPAK56D half-bridge MOSFETs are the BUK7V4R2-40H and the BUK9V13-40H. Both use the Trench 9 automotive silicon process technology, are rated at 40 V, and have been verified at twice the automotive AEC-Q101 specification in key tests. RDS(on) of the devices measures 4.2 mOhm (BUK7V4R2) and 13 mOhm (BUK9V13).

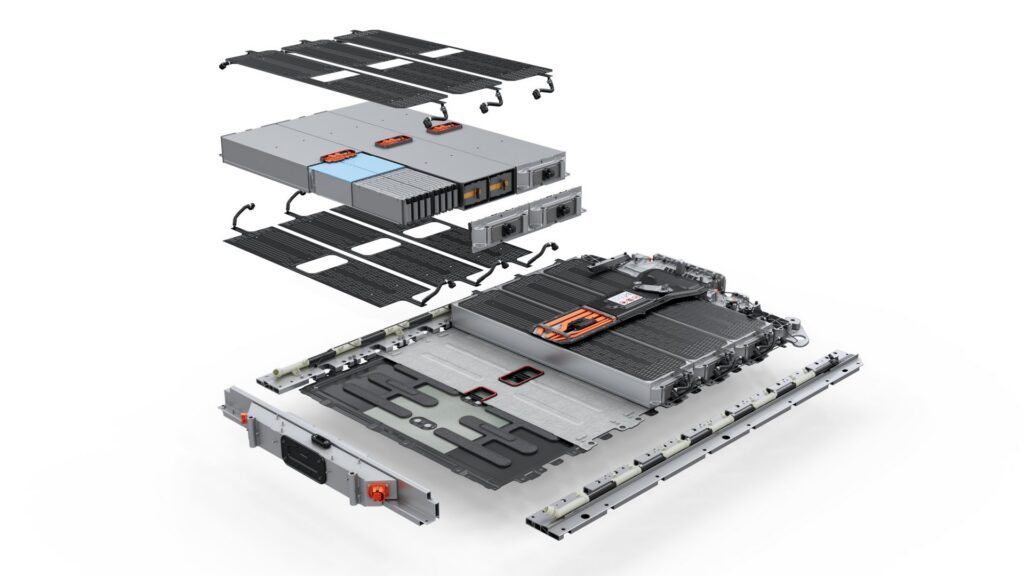

The AEC-Q101-qualified Nexperia LFPAK56D half-bridge package is designed for a range of 3-phase automotive powertrain applications such as fuel and water pumps, motor control and DC/DC power conversion. It occupies a 30% smaller PCB area and has 60% lower parasitic inductance for high-performance switching applications.

Source: Nexperia