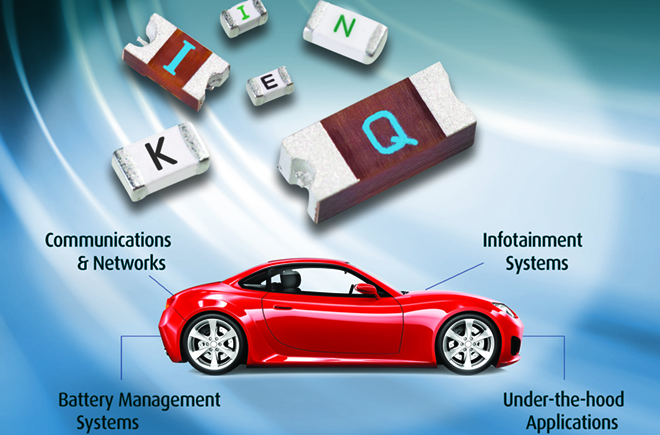

AEM Components’ new line of AEC-Q200 qualified surface-mount fuses is designed specifically for reliable operation in high-stress automotive applications. The new wire-in-air AirMatrix (QA Series) fuses feature current ratings up to 20 A / 250 V. The proprietary, hermetically-sealed wire-in-air structure is designed to assure consistent electrical performance.

The fusible element in the QA Series wire-in-air devices is uniformly straight across the internal cavity and externally bonded to the endcap through the plating process. Competitors’ units use solder beads inside a ceramic tube to bond the fusible link. According to AEM, this approach has the drawback of non-uniform performance and potential internal connection failure caused by mechanical/thermal stress such as vibration or bending, or by common soldering defects such as cold joints or poor wetting. Under high-stress conditions, the solder can vaporize, causing prolonged arcing that can lead to package failure and damage to the circuit board and surrounding components. AEM’s fuses are designed specifically to enhance reliability in harsh environments by eliminating the solder joint.

Source: AEM Components