An oft-cited concern about the transition to electric vehicles is the availability of high-speed Direct Current Fast Charging (DCFC) infrastructure to enable convenient travel beyond the single charge range of today’s vehicles. Many OEMs are considering a move to 800V architecture from the widely available 400V platforms of most mass market EVs.

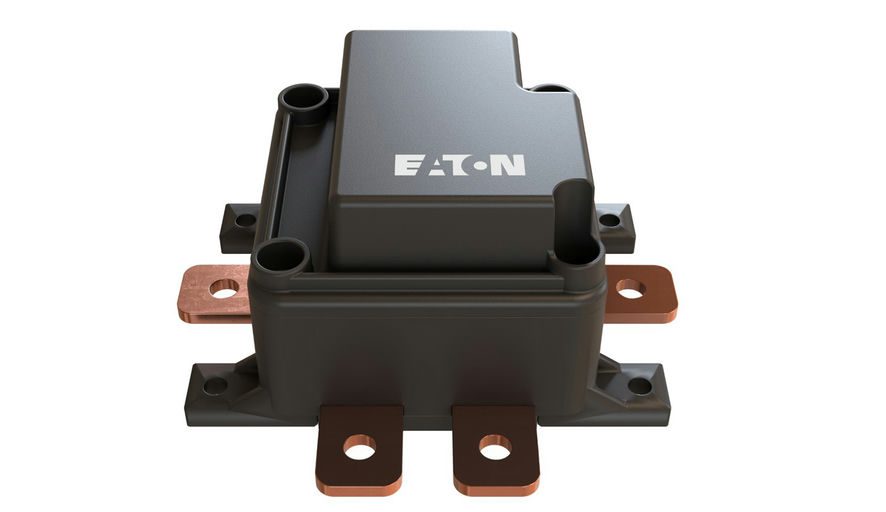

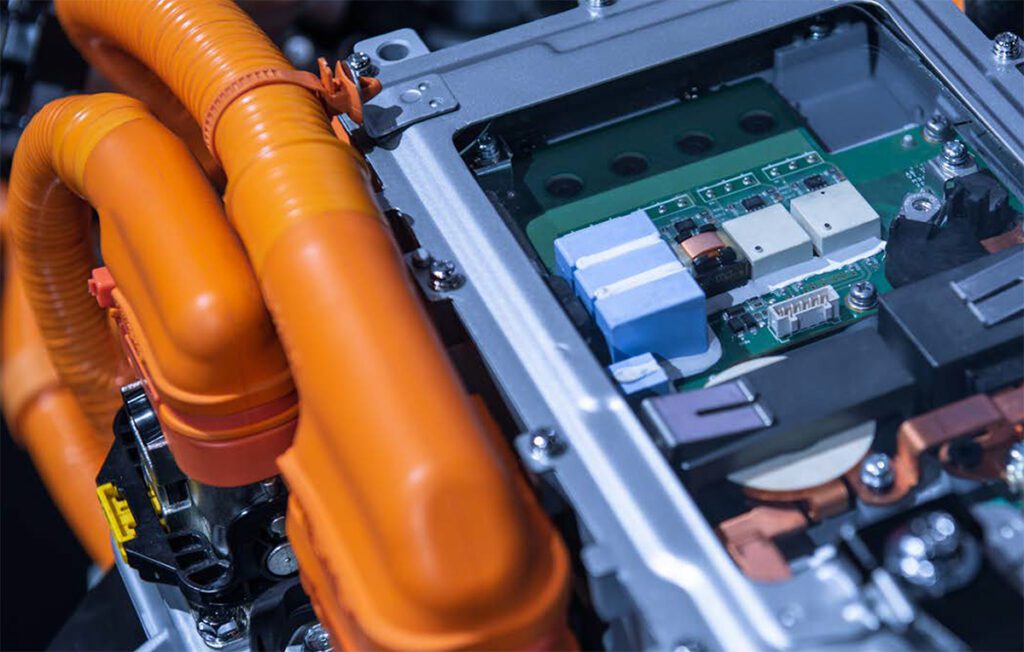

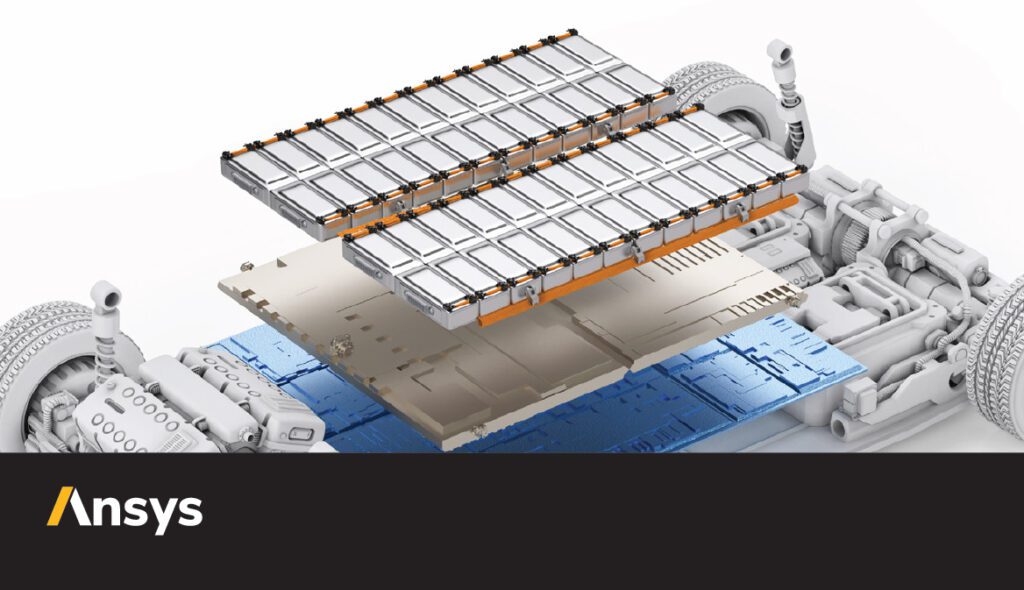

While this can have benefits to both vehicle efficiency and charging speed, it comes with a problem: much of the installed high-power DCFC infrastructure in the US and Europe is limited to 400 Volt, necessitating additional, costly equipment for an 800V vehicle to properly interface. Eaton’s Battery Configuration Switch (BCS) addresses this challenge with an innovative solution integrated into the EV battery pack.

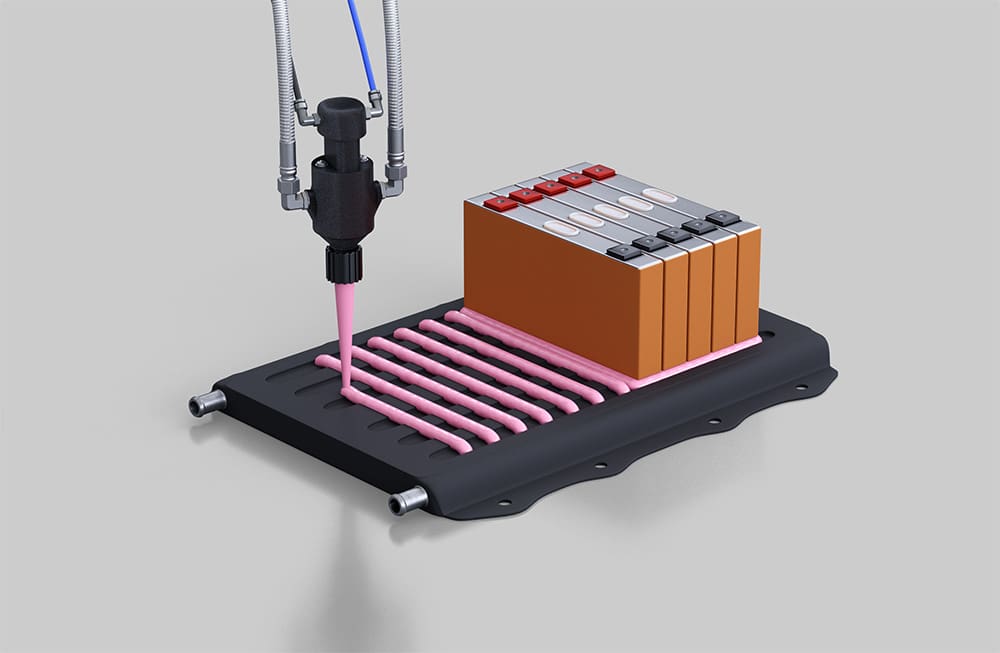

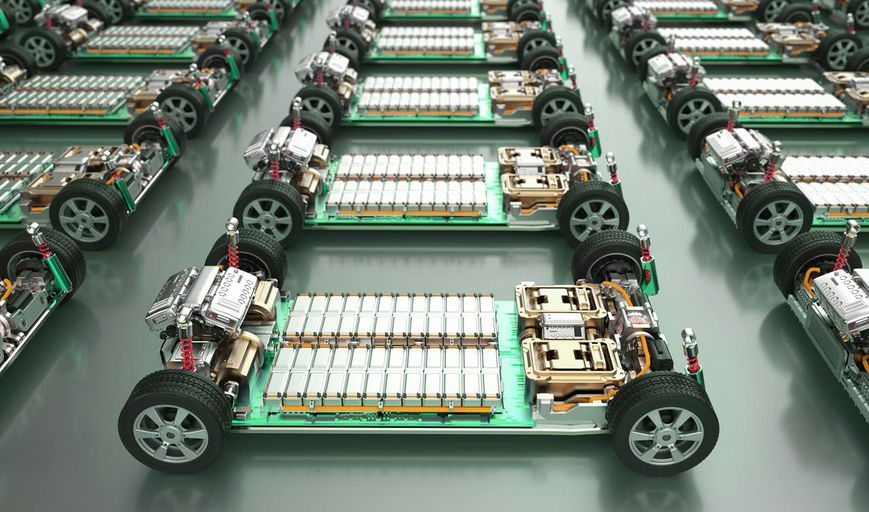

Designed for passenger and light-duty commercial vehicles, the BCS is a bi-stable device that efficiently transitions pack voltage between 400 and 800 volts to maximize charging speed on all publicly available infrastructure.

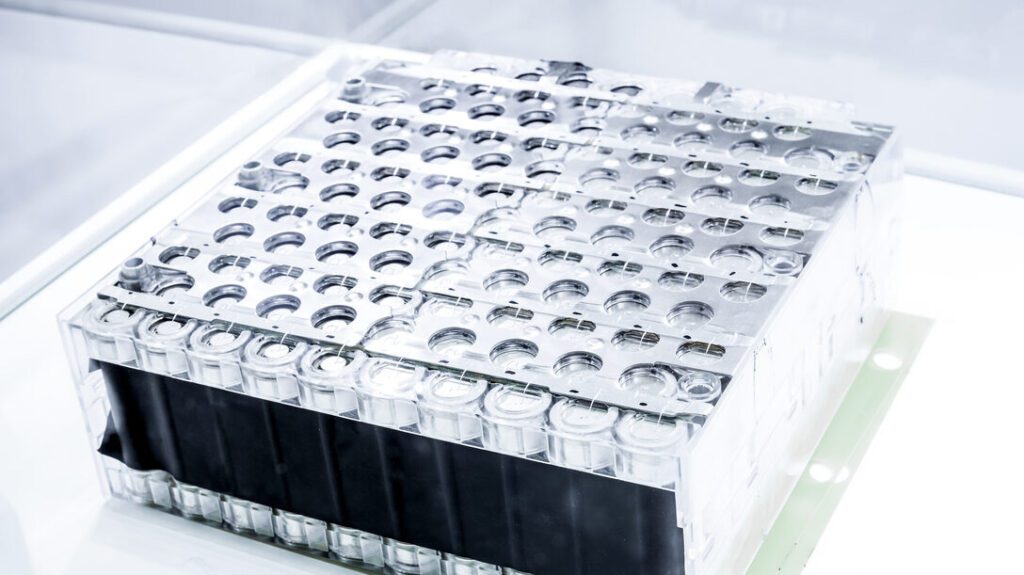

In its normal operating mode, the BCS connects two 400-volt sub-packs in series to achieve 800 volts. When a reduced voltage is needed, it reconfigures the battery into two parallel 400 Volt sub-packs, allowing the EV to charge efficiently on 400 Volt DC fast chargers. This reconfiguration capability eliminates the need for multiple contactors, busbars, and harnesses, reducing cost and complexity while enhancing charging performance.

The BCS also enhances safety by using an internal rotary switch to prevent short circuits from collisions, software bugs, or contactor malfunctions. It maintains a stable position without low voltage hold current, improving vehicle efficiency and ensuring functionality even if low voltage power is lost.

Join this webinar at next week’s Virtual Conference on EV Engineering, presented by Eaton to learn about how Eaton’s BCS represents a significant advancement in EV technology, offering a robust, efficient, and cost-effective solution for battery pack voltage reconfiguration, underscoring Eaton’s commitment to innovation and excellence in power management.

Other sessions at our next Virtual Conference include:

High-Voltage Protection In DC Fast Charging

Join this webinar, presented by TTI and Sensata, to gain knowledge about high-voltage DC protection, such as contactors, isolation monitoring modules and fast disconnects that can add innovation, expertise and scale to your projects.

HVDC systems demand robust protection mechanisms to ensure operational safety and reliability. This webinar explores critical components such as high-voltage contactors, which enable rapid and reliable disconnection using hermetically sealed arc chambers; isolation monitoring modules, which continuously assess insulation resistance to detect faults in EVs and charging systems; and fast disconnect devices like fuses and active fuses, which provide overcurrent and arc fault protection. Emphasis is placed on their design and operational principles in multiple applications.

See the complete session list for the Virtual Conference on EV Engineering here.

Broadcast live on March 10-13, 2025, the conference content will span the EV engineering supply chain and ecosystem, including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.