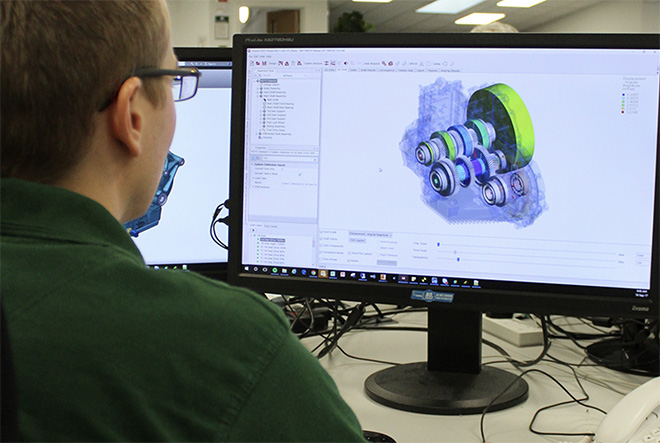

Drive System Design (DSD), a specialist in the rapid engineering and development of electrified propulsion systems, has enhanced its proprietary Electrified Powertrain Optimization Process (ePOP). This software-based tool is designed to help e-mobility providers swiftly identify the propulsion systems that best fit their specific needs.

DSD says its comprehensive analysis tool can quickly review tens to hundreds of thousands of powertrain combinations against cost, mass, range and efficiency, across multiple vehicle drive cycles, types and segments. Through the analysis, it can objectively pinpoint a highly targeted subset of powertrain configurations that best align with customer requirements.

Users can plot various attribute combinations, refine and focus on data inputs that give insight into attribute tradeoffs (e.g. power losses vs costs) and further analyze the most suitable powertrain makeup. Everything from rare earth material costs, ratio span and count, performance, motor topology, inverter technology, power density and more, can be mapped out using ePOP.

A core focus of ePOP is to go beyond the way each individual motor, inverter and transmission behaves, and instead focus on how they work together at an integrated system level.

“With the shift in demand trending toward highly efficient electrified propulsion systems, the conversation has changed from which parts are most high-performing and cost-effective on their own to how they work together as an optimized, integrated system that delivers ultimate efficiency at minimized cost,” said Senior Engineer Lee Rogers. “Our intuitive ePOP tool offers a simulated environment that gives us the whole system-level picture, supporting us in answering those fundamental questions and significantly shortening the innovation stage of powertrain development for our customers.”

Source: Drive System Design