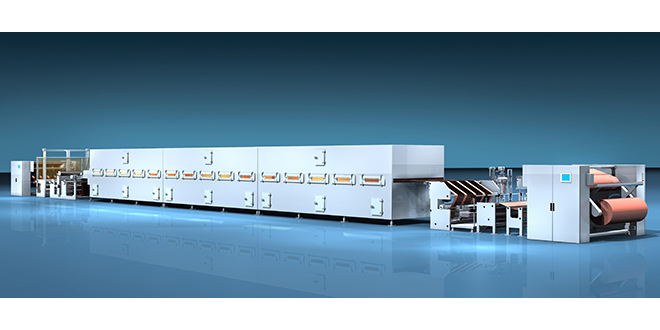

Babcock & Wilcox MEGTEC’s new GigaCoater wide-web coating line for lithium-ion battery electrodes is designed to facilitate high-volume production of battery electrodes.

The GigaCoater coating platform uses B&W MEGTEC’s simultaneous 2-sided coating system. The dual-coating method, in combination with coating rheology, maximizes production time and delivers in-line quality control. Each GigaCoater can produce up to 3 GWhr of electrode per year.

Specifications include:

- Web width of 1,300 mm

- Coating width of 1,200 mm

- Mechanical speed of 50/m/min

- Process speed of 40 m/min

- Wet coat weight of up to 400 gsm/side

The GigaCoater is designed to maximize volume at a lower production cost. According to MEGTEC, it use 50 to 70 percent less floor space than typical single-side coating operations, and its web width significantly reduces the number of coils needing to be handled.

“The energy storage industry is demanding a significant reduction in production costs, in combination with increased yields and product quality,” said Jeff Quass, VP of Technology and Development, B&W MEGTEC. “The GigaCoater offers increased foil width and faster speeds. Coupled with our simultaneous two-sided coating system, the GigaCoater provides a simplified coating line that approximately doubles manufacturing capacity within the same footprint as a single-side sequential line.”

“Manufacturing large quantities of lithium-ion battery cells requires dimensional up-scaling of the production equipment and output per line to achieve industry targets,” Quass notes. “At the same time, the benefits of two-sided simultaneous coating technology become increasingly important the wider and faster coating lines are required to get.”

Source: Babcock & Wilcox MEGTEC