At this year’s Battery Show in Detroit, Charged spoke with four of Schaeffler’s subject-matter experts to explore the company’s innovations in electrification and energy storage. The discussion began with Rashid Farahati, Vice President of the Corporate Competence Center for the Americas.

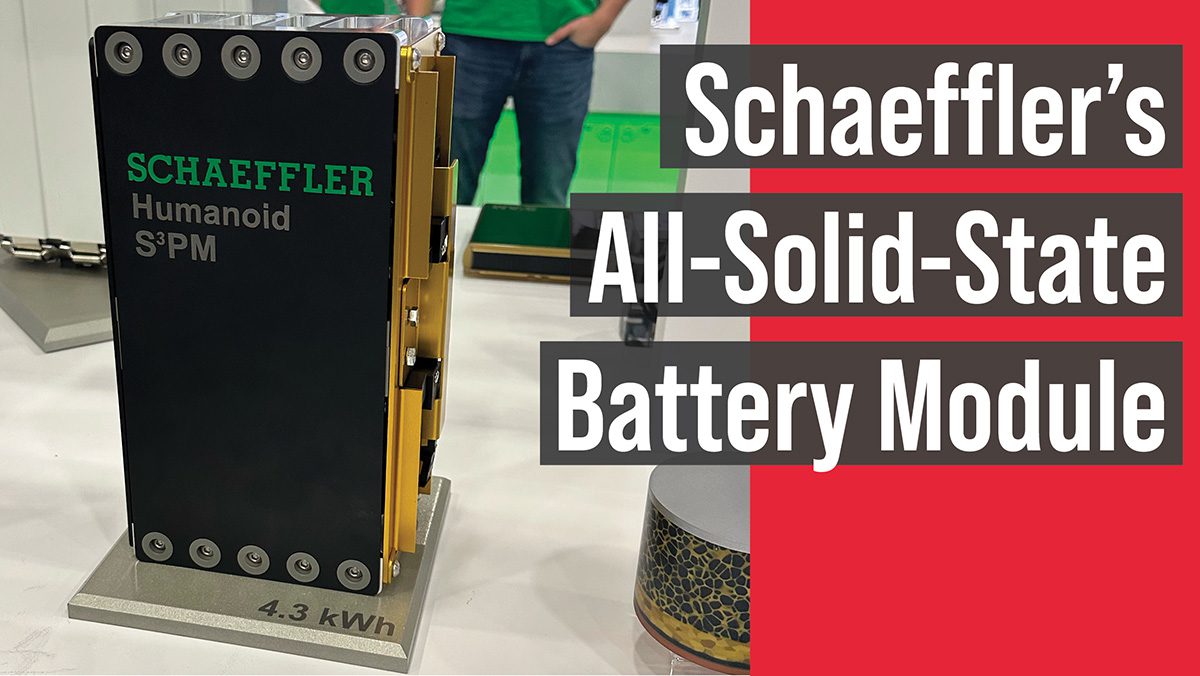

Farahati explained that while solid-state batteries promise higher energy density, safety and faster charging, they face a key challenge: they require constant mechanical pressure—around two megapascals—to maintain optimal performance. To address this, Schaeffler developed a compact pressure-controlled module capable of maintaining up to five megapascals, giving OEMs a practical solution for real-world applications.

Farahati also highlighted the design advantages of a true all-solid architecture. By removing the graphite anode and replacing it with a thin metallic layer, Schaeffler achieves up to a 40–50% reduction in cell volume, improving both range and weight efficiency. Eliminating flammable liquid electrolytes enhances safety and enables higher operating temperatures—up to 100 °C, compared with roughly 40 °C for today’s liquid systems—reducing the need for complex thermal management hardware. Together, these changes promise to translate to simpler, safer and potentially faster-charging battery packs.

Next, we spoke with Schaeffler VP Jerry Dixon, who showcased the side-by-side off-road demonstrator. The vehicle integrates a complete electric drive system—including an e-axle, charging electronics and thermal management—to illustrate the company’s systems engineering approach. The demonstration underscores Schaeffler’s emphasis on real-world validation and end-to-end system compatibility.

The third expert, Micah Steiner, Technical Project Lead, introduced Schaeffler’s magnet-free electrically excited synchronous motor (EESM). By replacing rare-earth permanent magnets with electromagnetic excitation, this motor eliminates dependence on scarce and expensive materials while maintaining comparable power and torque density. Steiner explained that this approach not only lowers material costs but also simplifies recycling and supply chain management—a growing concern in the global EV industry.

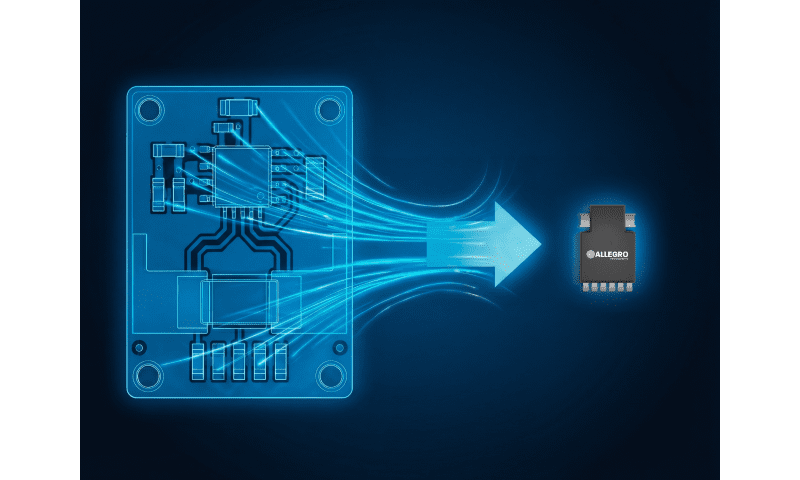

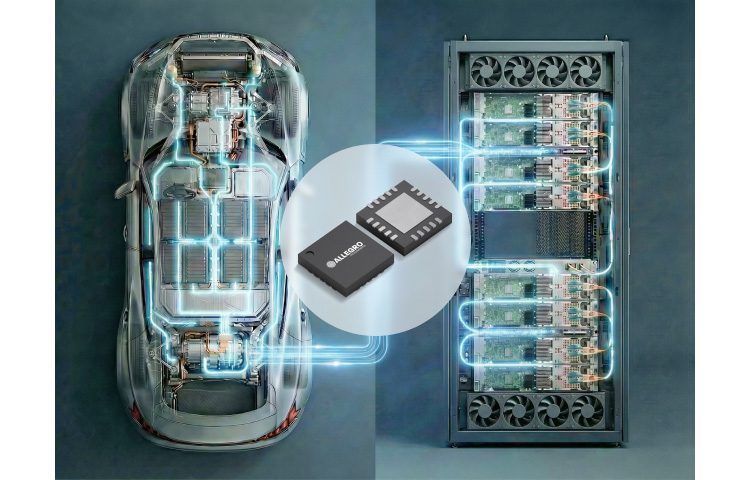

Finally, Mitchell Koupal, Product Manager, discussed Schaeffler’s broader portfolio of thermal management and sensing components designed to support advanced battery systems. These include battery immersion coolers, current and pressure sensors, thermal runaway detection devices, and control electronics that manage data from multiple sensors. Koupal also highlighted Schaeffler’s work in cell housing and stamping technologies, ensuring lightweight yet durable protection for prismatic cells. Together, these components demonstrate how the company’s manufacturing heritage supports modern electrification needs.

Through conversations with Farahati, Dixon, Steiner and Koupal, Schaeffler’s integrated vision becomes clear: it’s not just advancing one component but building a cohesive ecosystem for next-generation electric mobility. From high-pressure solid-state modules to magnet-free motors and sophisticated thermal systems, the company’s multidisciplinary approach offers a glimpse into how future EVs might balance efficiency, sustainability and safety.

To learn more, visit https://www.schaeffler.com.