Researchers at Coventry University have developed a new solution for recycling EV batteries by recovering all metals in them using a process called bioleaching.

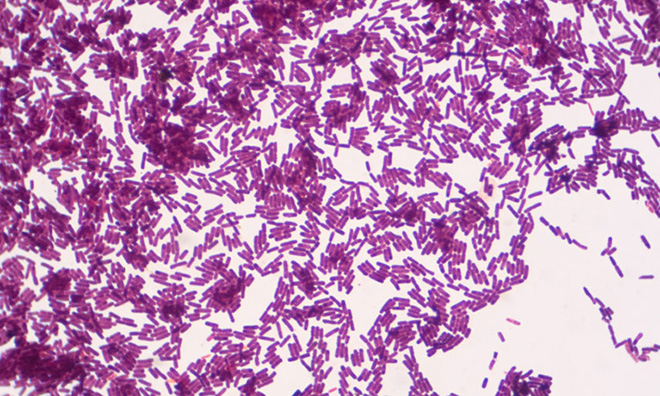

Bioleaching, also known as biomining, employs microbes that can oxidize metals as part of their metabolism. The process has been widely used in the mining industry to extract valuable metals from ores. More recently, it has been used to recover materials from electronic waste such as printed circuit boards and solar panels, as well as from contaminated water and even uranium dumps.

Professor Sebastien Farnaud and his colleagues at the university’s Bioleaching Research Group have found that bacteria, including Acidithiobacillus ferrooxidans and other non-toxic species, can target and recover the individual metals in EV batteries, reducing the need for existing techniques which involve high temperatures or toxic chemicals. The purified metals can be recycled indefinitely back into multiple supply chains.

Professor Sebastien Farnaud says that bioleaching is more cost-effective and more environmentally friendly than current recycling processes. “Lithium-ion batteries are currently recycled at a meagre rate of less than 5% in the EU, and most batteries that do get recycled are melted and their metals extracted. These plants are expensive to build and operate, and require sophisticated equipment to treat the harmful emissions generated by the smelting process. Despite the high costs, these plants rarely recover all valuable battery materials. Bioleaching, on the other hand, can offer a more sustainable and effective solution to recycling electric car batteries.”

Source: Coventry University