Germany’s Schaeffler Group manufactures a vast variety of “motion technology” products, including many EV components. The company recently introduced several new products aimed at the electric construction machinery market. Electric drive systems are increasingly showing up on construction sites, particularly in Germany, where some local governments have banned legacy ICE vehicles from urban sites.

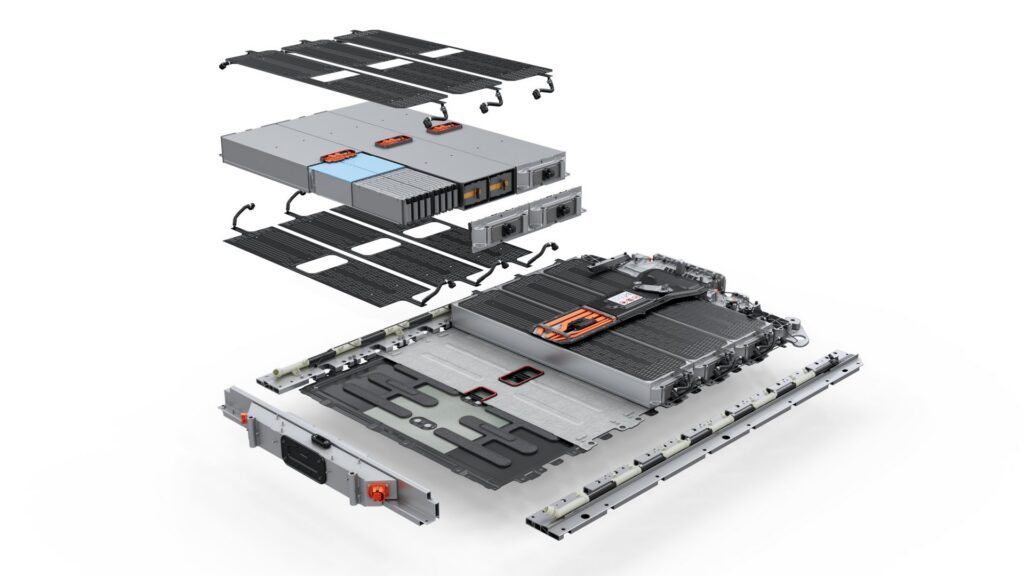

Schaeffler has introduced a new line of 800 V liquid-cooled heavy-duty electric motors for all-electric and hybrid drive systems. These achieve especially high torques, a power-to-weight ratio (peak) of around 5 to 7 kW/kg, and maximum efficiencies of more than 97% in a speed range of 3,000 to 8,000 rpm. “The low losses of the drive motors are essential to allow long operating times between charging cycles on construction sites and ensure efficient use of energy,” Shaeffler explains.

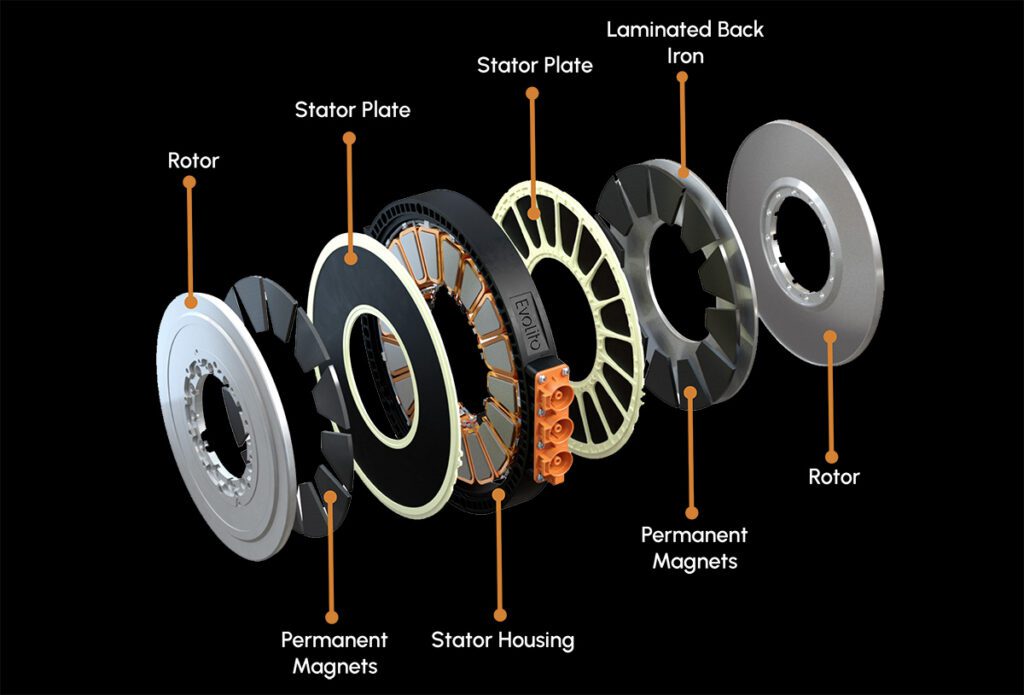

The modular motor series consists of three variants with maximum outputs of 125, 299 and 315 kW. The only difference is the length of the active parts. The individual stator laminations and the A- and B-side bearing end shields of the motors are identical in each case, thus facilitating cost-efficient manufacturing. The stator windings are designed as flat wire (continuous hairpin) windings, also known as wave windings.

Recently, at bauma, Schaeffler also demonstrated a complete electric axle with integrated heavy-duty electric motor.

The offroad sector of Schaeffler’s Bearings & Industrial Solutions division now offers a comprehensive range of electric drives with continuous output of 1 to 300 kW for the construction equipment industry. Schaeffler can supply a wide range of active-part components and complete systems such as wheel-hub drives based on permanent magnet synchronous machines. All crucial manufacturing technologies also come from a single source: the stator laminations stamped in-house, the hairpin and wave winding technology, the automatically produced coil windings, and the HV plug connector systems.

Other Schaeffler products aimed at the off-highway EV market include:

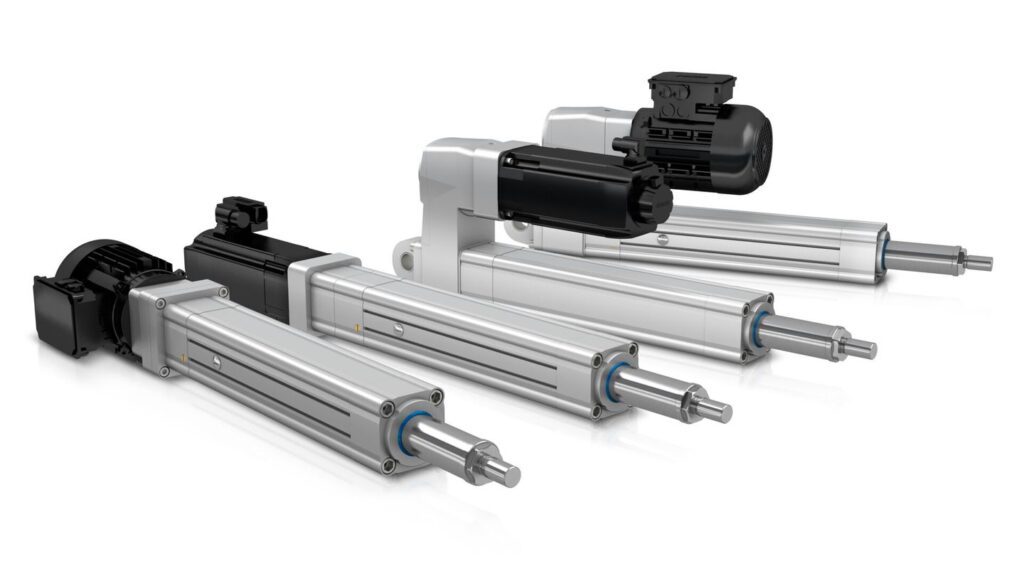

- Electromechanical linear actuators. The CAHB10 and CAHB2x actuators, with rated forces of up to 10 kN, were specifically developed for auxiliary functions in off-road applications, such as earth-moving and road equipment. Typical applications include signal light adjustment, ergonomic seat adjustment, opening and closing of heavy covers and engine hoods, roof height adjustment, swiveling of cabs and raising of jibs.

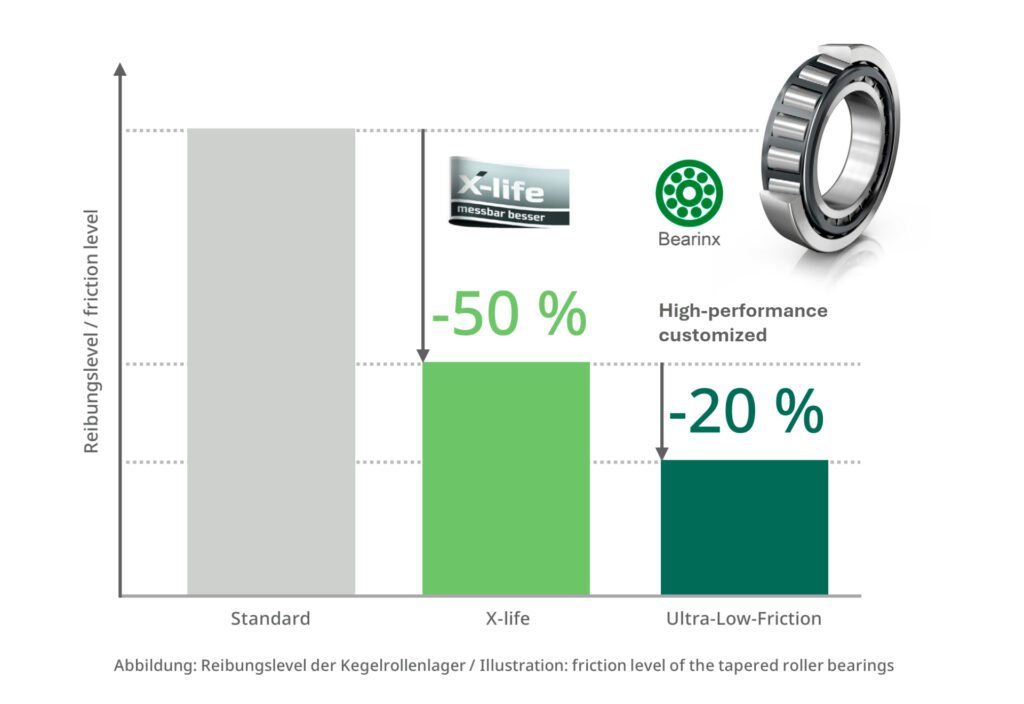

- Low-friction roller bearings. Rolling bearings inherently offer low friction, but Schaeffler’s development engineers have been able to substantially reduce friction even more through targeted optimization measures. Cylindrical roller bearings can be ideal for use in integrated planetary gear bearing arrangements. They offer a major advantage in applications with minimal installation space and high radial load. Reduced friction can have a direct impact on the energy consumption and thus the emissions of construction machinery.

- Sensors. In order to push construction machinery to its performance and loading limits while avoiding machine breakdowns, the stress on machine components needs to be measured. Schaeffler’s torque measurement modules capture data during operation, and transmit it via an analog or CAN-bus interface, allowing the data to be used for optimized control of operating functions, for safety functions, and for needs-based maintenance. The Schaeffler LoadSense-Pin allows stresses in metal components to be measured, so critical operating conditions and load peaks can be identified and operating costs reduced.

- Maintenance-free plain bearings for kingpins and chassis joints. Kingpins and chassis joints are subjected to high forces and strong shock loads, making them subject to false brinelling, a wear phenomenon caused by insufficient lubrication in the rolling contact. At bauma, Schaeffler introduced a new concept to replace tapered rolling bearings on kingpins and chassis joints with maintenance-free, dry-running plain (sleeve) bearings. These patented bearings are fitted with the Elgoglide sliding layer, which withstands dynamic contact pressures of up to 300 N/mm2.

Source: Schaeffler