Honda was an early electrification innovator, but the disappointing career of its Insight Hybrid apparently killed the company’s interest in electrons. However, there are signs of a turnaround – the hybrid version of Honda’s Odyssey minivan, launched in Japan in February, now accounts for 70% of Odyssey sales.

Now Nikkei Asian Review reports that Honda plans to expand electric motor production capacity at its factory in Hamamatsu, adding a third motor production line in October.

In partnership with Daido Steel, Honda has developed a magnet that does not require rare earth elements such as dysprosium. Motors using the new magnet will soon go into mass production, and will make their debut in Honda’s redesigned Freed minivan, due out this month.

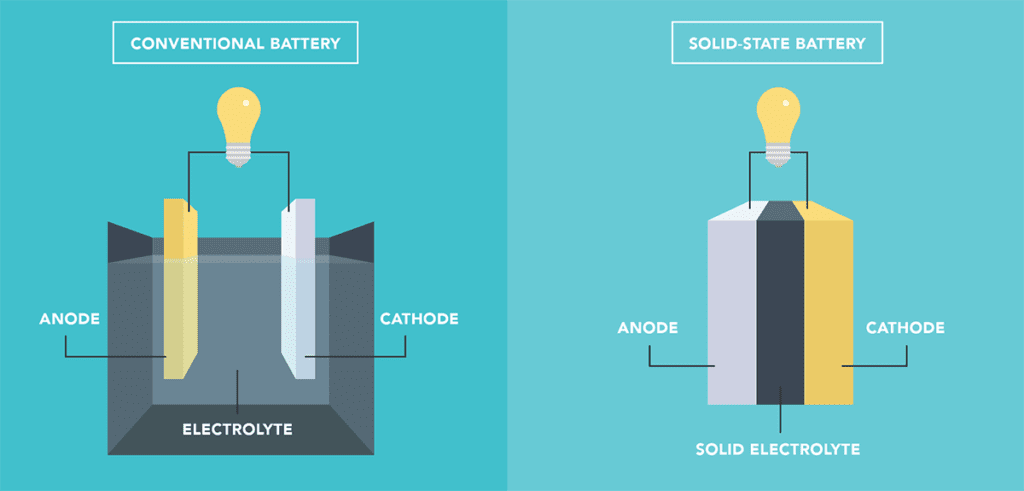

The neodymium magnet is made using a hot deformation process, which produces a fine crystal grain structure that is ten times smaller than that of a sintered magnet. It offers high heat resistance and high magnetic performance, making it ideal for use in hybrid drive motors.

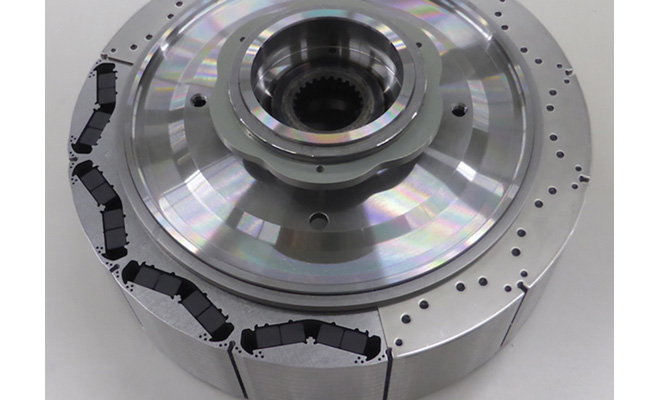

Honda also designed a new motor that features a revised rotor shape to optimize the flow of the magnetic flux of the magnet.

Nikkei also reports that Daido Steel plans to build a neodymium magnet factory in the US to meet growing demand from hybrid- and EV-makers. The plant is scheduled to be up and running by 2019, and the company plans to invest around $100 million by 2026.

Source: Nikkei Asian Review via Green Car Congress