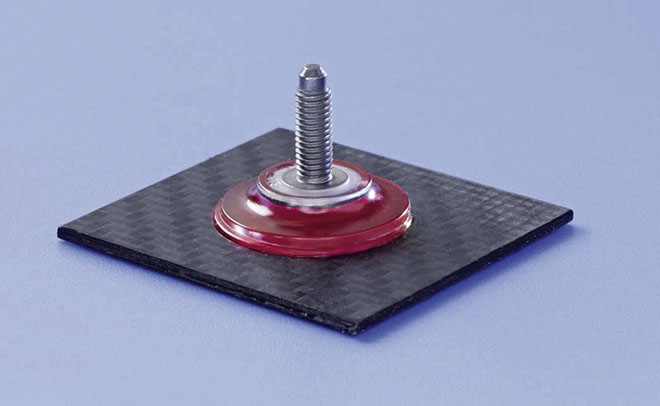

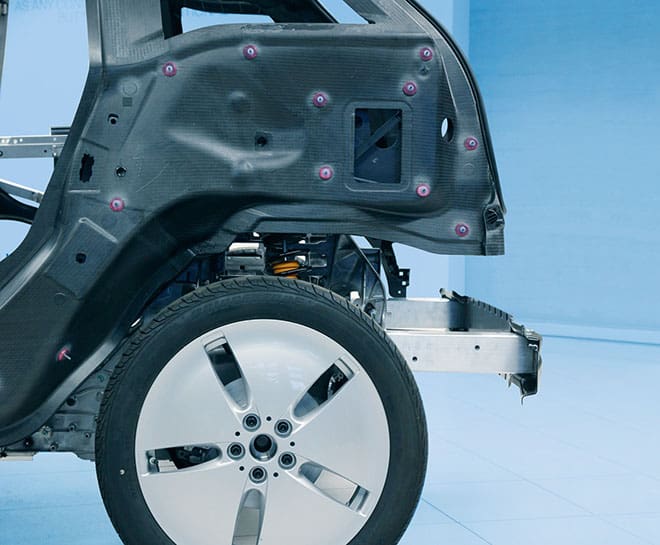

Assembly specialist Böllhoff and adhesive expert DELO have developed a new joining method for lightweight materials using a bonded bolt called ONSERT. The technology is ideally suited to carbon fiber reinforced plastic (CFRP), and the companies have tested it in a pilot project that secured cables, claddings and other components of the BMW i3.

DELO points out that composite materials such as CFRP take established joining technologies (welding, screwing, riveting) to their limits. ONSERT combines bonding and screwing by equipping fastening elements, such as threaded metal bolts, with a transparent plastic base and bonding it to fiber composite materials.

The adhesive is cured in about 4 seconds using an LED lamp, and the process can be fully automated. Bonded bolts with a base diameter of 25 mm achieve a pull-off strength up to 2,000 N on CFRP. When applying higher forces, a predetermined breaking point in the base ensures that the laminate of the composite material remains intact and no fibers are torn out.

ONSERTs are designed to offer flexibility in design and production. The structural shape can be defined by the user, particularly in terms of rod length and base diameter, and bonded bolts can be attached to the raw body prior to final assembly of lacquered elements.

Source: DELO via Green Car Congress