Battery researchers around the world are working on lithium metal electrodes, which have the potential to greatly increase energy density. But the drawback to lithium in this form comes in the form of dendrites, root-like lithium deposits that form on the metal surface and can harm performance and even lead to short circuits.

Now a team of researchers at MIT says it has carried out the most detailed analysis yet of exactly how dendrites form.

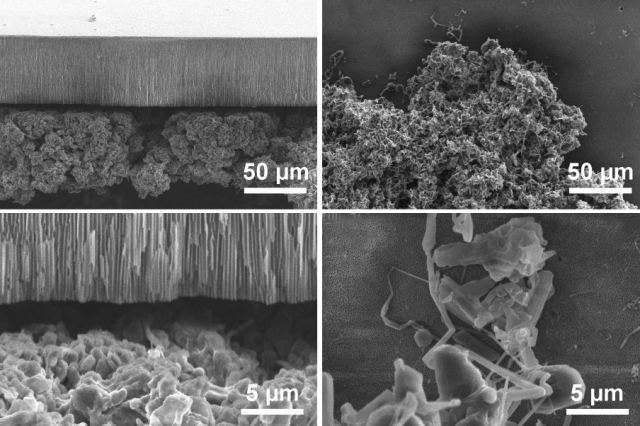

In “Transition of lithium growth mechanisms in liquid electrolytes,” published in the RSC journal Energy and Environmental Science, Peng Bai, Martin Z. Bazant and colleagues report that there are two different types of deposits, both composed of lithium filaments.

Clustered, “mossy” deposits, which form at low rates, grow from their roots and can be relatively easy to control. The sparser and faster-advancing “dendritic” projections, which grow only at their tips, are harder to deal with and are responsible for most of the problems.

The root-growing mossy growth, the team found, can be blocked by adding a separator layer made of a nanoporous ceramic material. The tip-growing dendritic growth can’t be easily blocked, but fortunately, the normal working currents of practical batteries are much lower than the current associated with the tip-growing deposits, so they won’t form unless degradation of the electrolyte has occurred.

In theory, replacing carbon-based anodes with lithium metal could cut the weight and volume of lithium-ion batteries in half, Bai explains. But those pesky dendrites are still poorly understood. “Those small fibers can go right through the separator and cause explosions or fires,” says Bai.

At right, scanning electron microscope (SEM) images show the two types of lithium deposits, the bulky, mossy type (at top), which grows from its base, and the needle-like dendritic type (bottom), which grows from the tips. At left, SEM images show the effect of a blocking layer of ceramic material that limits the growth of the mossy deposits.

The separators that could block the mossy growth are made of anodic aluminum oxide, which is 60 micrometers thick and has well-aligned, straight nanopores across its thickness. “It’s a big discovery, because it answers the question of why you sometimes have better cycling performance when you use ceramic separators,” Bai says. The research suggests that flexible composite ceramic separators, such as those made by coating ceramic particles onto conventional polyolefin separators, should be used to help block the root-growing mossy lithium.

Bazant explains that most previous research on the use of lithium metal anodes has been carried out at low current levels or low battery capacities, and because of that the second type of growth mechanism had not been reliably observed. The MIT team carried out tests at higher current levels that clearly revealed the two distinct types of growth.

The new findings will provide researchers with a better understanding of the underlying scientific principles, and show “what are the limitations on rates and capacity that are achievable,” Bazant says.

SEE ALSO: Arbin’s new battery testing equipment offers a glimpse into the future with ultra-high precision

Source: MIT News via Green Car Congress

Images: Peng Bai