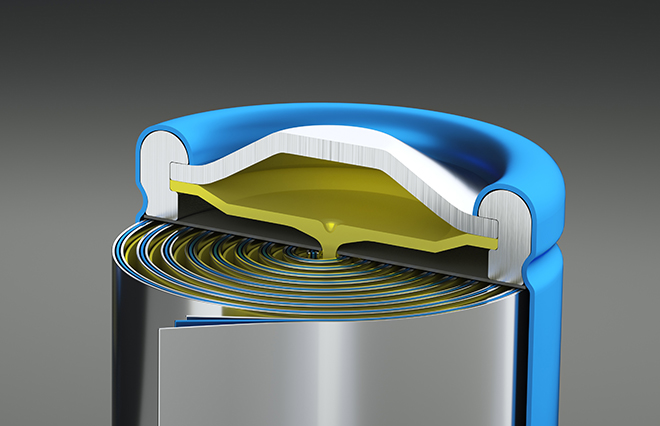

Miltec UV has been awarded a contract from the Defense Logistics Agency to demonstrate the cell technology to produce solid-state lithium-ion batteries using Miltec’s UV-cured Gel Polymer Electrolyte. This technology could accelerate the advancement of solid-state lithium batteries.

Miltec is working with battery manufacturer Saft to develop and provide test cells fabricated with a UV-cured polymer-based electrolyte on lithium metal anodes. The application of UV-curable chemistry in producing solid-state electrodes is expected to lead to a faster, continuous, scalable, high-speed fabrication process for applying polymer-based electrolyte on lithium metal anodes. Miltec says the process could result in 50% greater energy density at the cell level and a 25% increase in specific energy.

This project is aimed at developing an outline for a solid-state battery electrode fabrication process and demonstrate cell-level performance for two types of DLA batteries: the BB-2590 rechargeable lithium-ion battery and the Conformal Wearable Battery (CWB). Miltec President Bob Blandford said, “This innovation allows lithium-ion battery manufacturers to offer batteries with improved safety and performance at significantly reduced manufacturing costs.”