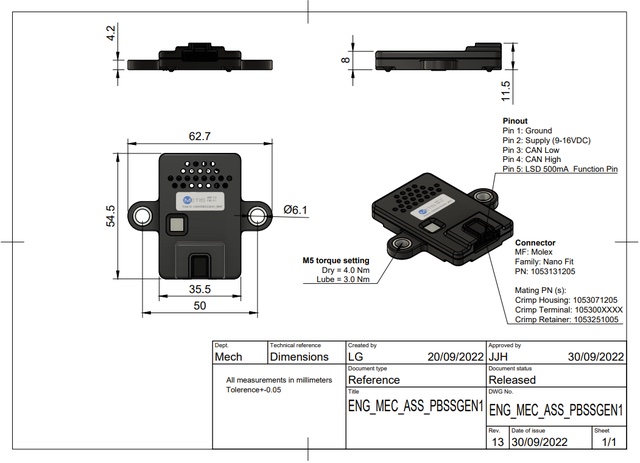

Metis Engineering has earned ISO certification of its Production Battery Safety Sensor, which designed to monitor the health of a lithium-ion battery pack and detect cell venting. The sensor was developed using ISO26262 processes, and has been tested to ISO Automotive Standards by Applus+ 3C Test, an independent testing house.

Manufacturing of the production version of the Battery Safety Sensor has begun in the UK to fill orders from OEMs and Tier 1 suppliers, which are using them in ASIL B applications.

“Our Battery Safety Sensor measures pressure change and volatile organic compounds (VOCs) for the detection of cell venting, which is an early stage of thermal runaway,” said Metis Engineering Managing Director Joe Holdsworth. “It also monitors humidity, dew point and air temperature parameters to ensure that the battery continues to operate in optimum conditions.”

The sensor is designed to pick up a range of environmental parameters to ensure that the battery continues to operate in optimum conditions, and has an optional accelerometer to record shock loads. This data can be used to crosscheck with other inputs, such as cell temperatures, to check for cell venting. The sensor relays the data over a configurable CAN interface to a control unit, such as the vehicle’s ECU, to alert the driver that cell venting has occurred. The sensor can also trigger a process to cut the circuit to the battery pack, allowing it to cool down and prevent thermal runaway.

Metis says its Battery Safety Sensor typically detects venting within seconds.

“Thankfully, EV battery fires are very rare, but when they do occur, they are usually catastrophic for the vehicle,” said Holdsworth. “As cells age, the chance of one in a pack of hundreds or thousands going bad increases significantly. The early detection of cell venting is vital to the safety of the vehicle’s passengers and everything in the immediate proximity. We hope that this sensor offers an affordable part of the solution.”

Source: Metis Engineering, Battery Tech News