Amsted Automotive has added new capacity and product offerings to serve the off-highway electric vehicle (OHEV) market in the US.

“It has always been Amsted’s strategy to manufacture in the customer’s region,” said Bill Kerfin, President of Amsted Automotive. “Having local engineering teams and manufacturing facilities improves efficiencies and minimizes costs, which is especially true today with quick-changing tariff policies.”

Several of the company’s 13 manufacturing facilities that are in the US are already positioned to manufacture components for the OHEV market.

“The off-highway EV market is extremely important to Amsted as we scale our powertrain technologies and powder metal and advanced metal-shaping technology,” said Warren Bennion, the company’s Director of Marketing.

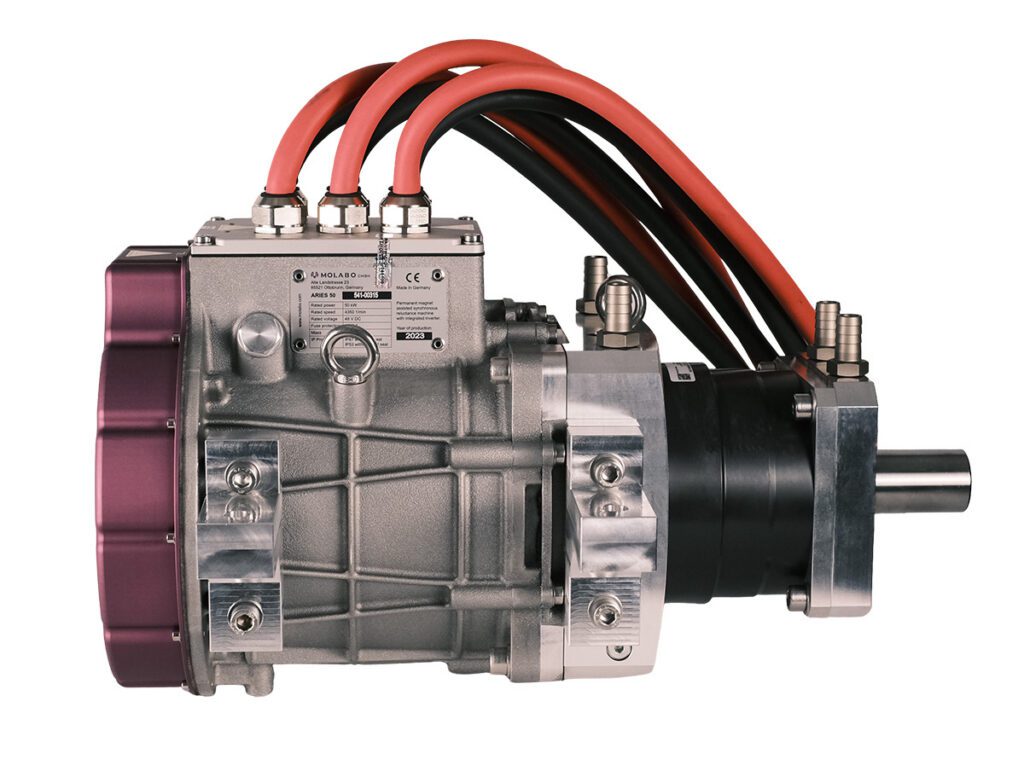

The Saginaw plant manufactures the Amsted eAxle Disconnect, which is currently in production for passenger electric vehicles and “can be scaled for agricultural and off-highway applications.”

The eAxle Disconnect enables a seamless and quick transition from two-wheel-drive to four-wheel-drive and back in EV and hybrid applications, and uses an ultra-efficient design based on the Amsted Dynamic Controllable Clutch (DCC) technology, which latches in state to reduce energy consumption, thereby increasing driving range by up to 10%.

Another product the company offers for the OHEV market is its wheel-end disconnect, which can be manufactured in any one of Amsted’s US plants. The electromechanical product features an implementation of the DCC within a hub assembly to provide seamless disconnect in heavy-duty electric drive axles. The features make such chores as vehicle towing and decking, or other maneuvers in which axle disconnect is necessary, effortless by eliminating the need to change wheel hub geometry.

Source: Amsted Automotive