Exro Technologies is building a future in which an EV’s motor, drive, gearing and AC charging system are integrated into one highly compact and efficient system.

Engineers are always looking for cost-effective ways to get the most range out of an electric vehicle’s battery pack. Exro Technologies is triangulating on a solution with three core concepts: motor control, battery charging and powertrain optimization. Exro’s patented Coil Driver technology took home the Gold in the 2022 Edison Best New Product Awards in manufacturing, logistics and transportation. The original idea has now launched its own spin-off technology that enabled fast AC charging, eliminating the vehicle’s onboard charger and facilitating vehicle-to-everything (V2X) capabilities.

Exro’s newest partners include Vicinity Motor Corporation, which is piloting Exro’s high-voltage Coil Driver in its Lightning eBus, and evTS, which will use Exro’s low-voltage Coil Driver starting in 2023. Exro has innovation and manufacturing centers in Calgary, Phoenix and Ann Arbor, and a growing list of partners and products.

Charged recently chatted with Josh Sobil, Exro’s Chief Commercial Officer, to learn more about the company’s technology, its history and its vision for the future.

Charged: Exro started with an idea for a unique motor control system. Can you tell us how it works?

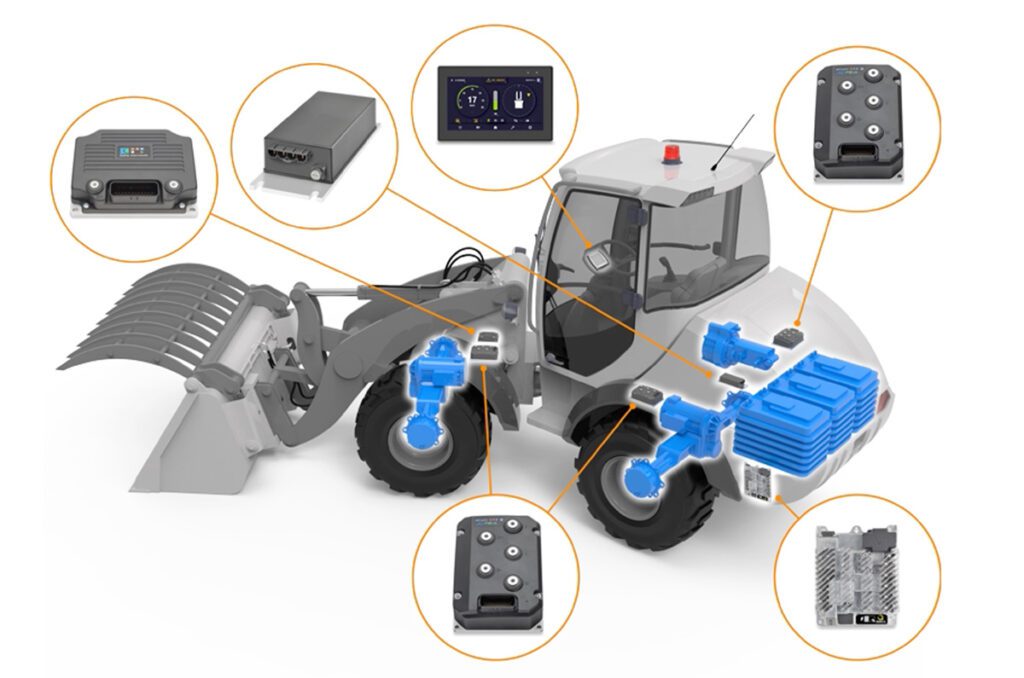

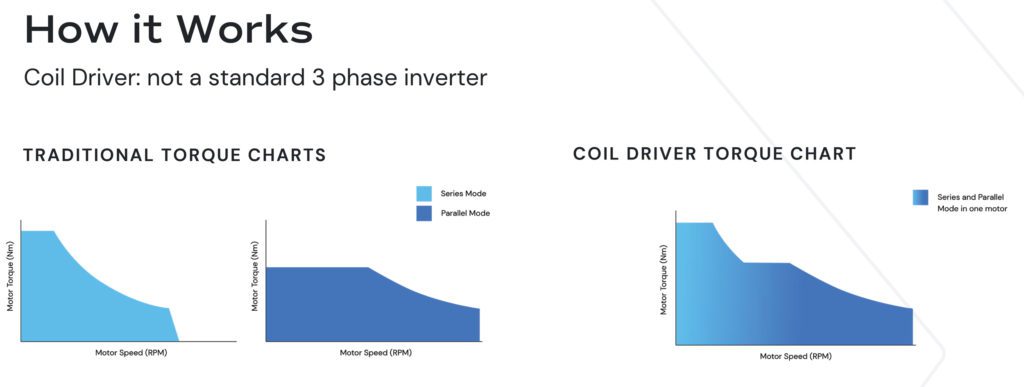

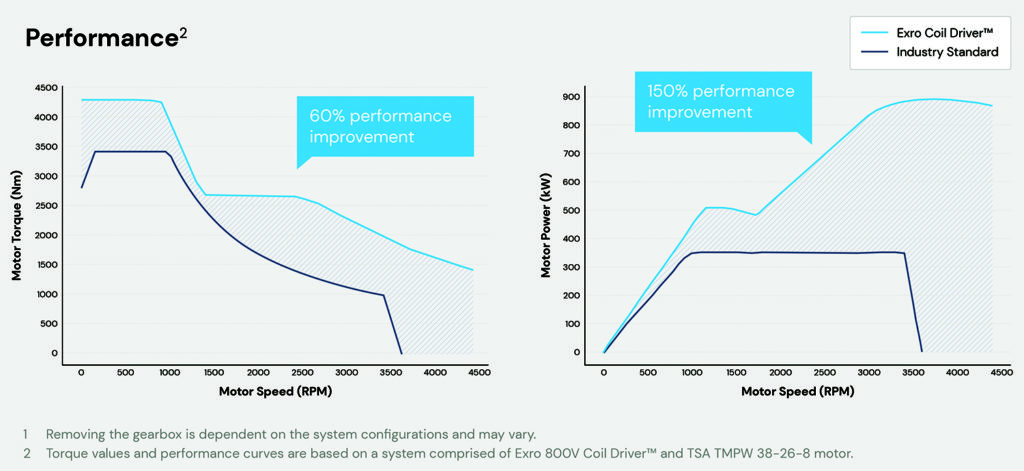

Josh Sobil: Electric motors are designed to deliver either high torque or high speed, depending on the way in which the coil windings are configured. Applications that need both torque and speed usually require either a motor/gearbox combination or more than one motor, adding weight, cost and complexity to the system. Exro’s core technology is a unique motor control system, the Coil Driver, in which the motor coils are wound so that they can be reconfigured on the fly to efficiently provide the requisite torque or speed, without the need for a gearbox or multiple motors.

You can start the machine in a series configuration, which provides a high current density and a very high torque. Then it can switch to a parallel situation, which reduces the impedance of the coils and delivers more power while maintaining the motor’s efficiency.

The theory behind the Coil Driver is the ability to drive the machine in two different configurations. You can start the machine in a series configuration, which provides a high current density and a very high torque. Then it can switch to a parallel situation, which reduces the impedance of the coils and delivers more power while maintaining the motor’s efficiency. The key advantage is the ability to expand that efficiency map or that torque envelope, and get more out of the same frame, so we can reduce the machine’s cost and improve its performance. The Coil Driver gives the engineer another option to tweak the design of the powertrain and get more out of the machine.

There are cases where we use smaller machines to get the same amount of power and torque that’s required out of a given drive cycle, or we get rid of components like the two-speed gearbox in applications that only need a low gear to provide five to ten seconds of very high starting torque. We see a lot of that in the commercial vehicle space. Any time you can remove components and improve efficiency, it’s an advantage to our customers [because] they can either reduce the size of the battery or remove other components that might be more costly.

Charged: Can you feel the shift when you switch the topology of the drive, like shifting gears?

Josh Sobil:It shifts in about ten milliseconds. We have noticed a little kick, but in a commercial vehicle or a car, it wouldn’t even register because the inertia would just absorb it. On a motorcycle or something small, there might be a little kick, but we can program it so you don’t feel it. That’s part of our secret sauce—the ability to switch very quickly without a torque interruption, especially in commercial vehicle applications. Having a torque interruption is quite a big deal because you’ve got so much inertia to overcome. Anytime you’re on a hill and you interrupt the torque it’s just more work that you have to do, and more stress and strain on the actual system. So, the faster you can switch, the more advantageous it is.

Charged: Where did the Coil Driver idea come from? What’s the history behind it?

Josh Sobil: It’s kind of your classic startup story. The founder, Jonathan Richie, was a garage inventor, as they say, with an interest in wind power. He was looking at the fact that windmills generated power at various torques and speeds, only a few of which would be at the optimal setting. At one time, it might only be working at 85% efficiency, versus 96% efficiency at exactly the right load. So he thought, “If I could change the circuit inside the machine [on the fly] then maybe I could get different operating points to have higher efficiencies [across the whole operating curve]. If I could start to meld those together, then I could see an overall increase in generator efficiency.”

As a startup in a garage, the challenge was breaking into a wind generation market that’s working with megawatt-level machines. Designing products for that market was prohibitive from the start. That’s not to say that it’s not a good use case—I think it will be, but there was also an EV market opportunity that was building. An EV motor has a profile where, if you look at a machine’s torque curve and then plot all of the operating points that an EV actually operates under, it almost fills the entire torque map. So we determined that this is probably a more accessible market, just from a commercialization standpoint. For example, we could design a hundred-kilowatt inverter for an off-highway application, which is a lot less stringent than even an automotive application or a wind power application. So there are ways to get into the EV market, although the barriers to entry are absolutely massive. We’re looking to our partners to help bring us into the bigger automotive sector.

Charged: There must be a cost-benefit analysis that you work through with the different applications, like off-highway or commercial trucks. What’s the main application that you’re working on right now?

Josh Sobil: We’re looking at urban and highway applications, which require a very high peak efficiency across the entire operating range—what’s called an efficiency island—and that’s exactly what the technology does. So if the vehicle is operating at low speed, we can deliver the torque to get started, maybe to climb a very steep incline. That might provide a new route that a garbage truck can take in the city, improving the efficiency of the overall operation. And there’s an expansion of that curve so that the efficiency is better at highway speeds as well. That’s definitely where we see the Coil Driver shine.

We’re looking at urban and highway applications, which require a very high peak efficiency across the entire operating range—what’s called an efficiency island—and that’s exactly what the technology does.

There are applications that require a lot of torque down low, but they also need power at highway speeds. That’s a very typical trade-off in any electric machine. A gearbox gives high torque, but it can’t increase power. So we’ve seen a lot of interest in the off-highway sector, and even in motorcycles, which need a lot of power at the high end, but also want to be light.

The powertrain is a key component of the vehicle’s weight—the battery and the motor are going to be very heavy components. If we can lightweight the motor and still deliver the power and torque, then it’s a good application. We’re also working with partners in the passenger car sector. By removing the onboard charger and integrating three-in-one configurations, we’re reducing both cost and weight. And that’s what we’ve seen the OEMs wanting. When you show an efficiency benefit, they’re going to ask, “How much smaller can I make my battery?” That’s the dollar factor that they’re going to apply.

Battery charging

Charged: You mentioned removing the onboard charger. How does Exro’s technology affect battery charge control?

Josh Sobil: That feature was a byproduct of the way the topology was built up. What’s interesting is the ability to do this with an AC frequency, so you don’t need a DC supply to charge quickly. If you have a very high continuous power that you can send through the powertrain, you can charge at a considerably higher power than what you might get out of a DC fast charger. It’s something that we’ve been testing and proving out, and we’re expecting to release it in our second generation of drives. We’ve now got a patent pending for the ability to charge through the Coil Driver.

All of our high-voltage products can accept this, so you could use it in a passenger vehicle as well. We’ve demonstrated charging above 20 kW right now, just with the standard Coil Driver. Once we move to the higher powers, then we have continuous power ratings up into the hundreds of kilowatts, so this is something you could put on a passenger car. You would need to look at the infrastructure and ensure that the plug was appropriate, but it would replace the EV’s onboard charger.

Effectively we’re using the drive itself as the onboard charger. It’s a four-quadrant drive, so we can run power in both directions. The same way you would regenerate while you’re braking, you can convert AC power to DC power through the drive.

Effectively we’re using the drive itself as the onboard charger. It’s a four-quadrant drive, so we can run power in both directions. The same way you would regenerate while you’re braking, you can convert AC power to DC power through the drive. And that’s fundamentally all we’re doing. An inductive component is needed to do that, so we use the motor’s inductance.

Charged: Why doesn’t everyone design a motor drive that can also be used as the onboard charger?

Josh Sobil: Good question. Fundamentally, because the motor would produce torque, so you can’t use the machine unless it produces no torque. If you were to apply the current through a typical motor, it would naturally start turning. With the Coil Driver, since we can control the individual coils, we apply the current in an opposing fashion, so the torque cancels itself inside the machine. You have to make sure to cool the drive, obviously, because you’re going to have current and you’re going to have losses, but those are the main differences.

And I should also [point out that] there are others that have looked at doing this with a six-phase drive by opposing three of the phases. So we’re not the only ones that can do this, but it’s an added feature to what we’ve been able to do with just the topology of the drive itself and the way that we connect it to the machine. We don’t change anything in the drive, and fundamentally a drive can connect as a rectifier in that same way, but it’s the way that we connect that allows us to produce zero torque out of the machine. That’s a native advantage to the technology that, in all honesty, we realized a bit after the fact. We were focused on the torque envelope and efficiency and then we thought, “There’s discussion out there about using the drive as a charger, so could we use this?” So we made sure it worked and about a year ago we applied for the patent. Now it’s becoming a focal point because it’s a huge cost-saving feature.

Powertrain optimization

Exro offers engineering services to help its customers design or modify motors to accommodate its Coil Driver technology. The company provides a co-development platform to customize inverter controls that reduce the need for multiple motors and/or gearboxes and optimize battery usage.

Charged: So when you call it a three-in-one system, what three components are you referring to exactly?

Josh Sobil:The term three-in-one system refers to the drive, motor and gearing as an integrated drive unit. They’re known as e-axles or integrated drive units on the automotive side. And then you can imagine how much more compact it is without the charger, so you can do everything with that integrated drive system. That’s our vision—our roadmap for the future is really around being able to integrate everything in the EV’s powertrain. Trying to lightweight, downsize and make everything more compact at a system level has a desirable impact on cost.

Charged: Suppose you’re talking to a potential customer and they just want to increase the efficiency of an electric garbage truck. As a general example, how would you estimate the potential efficiency gains with your Coil Driver system?

Josh Sobil: What we’ve been simulating—and it obviously depends on the drive cycle a little bit—shows that commercial trucks tend to have around a 3-4% range increase. If you can remove 4% of a 200 kWh battery, at $135 a kilowatt-hour, then you’re saving roughly $1,000. Or you can keep the same size battery and get 4% more range at no extra cost.

We’ll be starting some real-world drive cycle testing this winter. We’re excited about that. It’s coming with one of our partners for an e-axle on a commercial truck.

Charged: So, you have the custom power electronics design and you couple that with a custom-wound motor. Will you always supply that combination as a package?

Josh Sobil: Depending on the customer, yes, we’ll sell it as a system. Some customers will design their own machine and we will couple the inverter to their motor. Fundamentally, we are not a motor manufacturer, but the technology requires that in some cases we have a machine to sell. We are not changing the magnetic design of the machine—we’re changing the way we connect to its coil groupings. It’s more of a mechanical interface for the cables. The drive itself just replaces a standard inverter, but what you would see are twelve connections—four per phase—going into the machine.

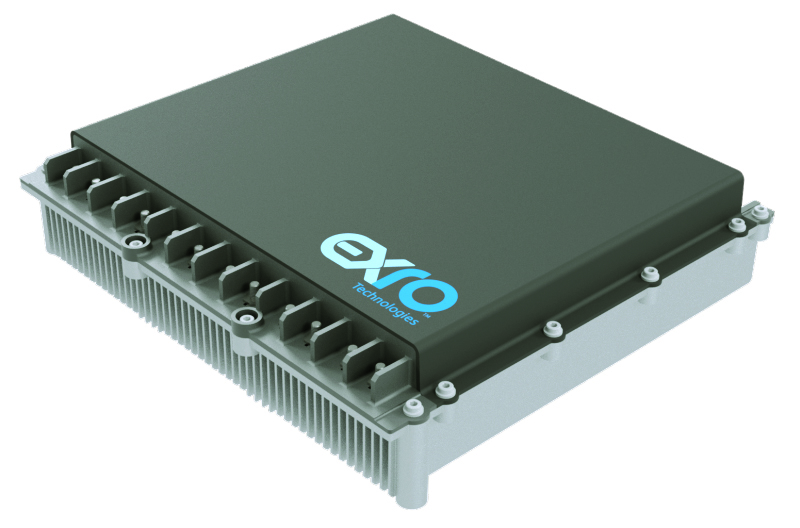

Charged: The fundamental hardware difference is that you have an inverter with a lot more switches than a standard one, right?

Josh Sobil: Exactly. We’re still using standard switching devices—the topology of the drive is what’s different. The circuit is unlike any other drive that’s out there because we’re driving individual coils, so it doesn’t look like a typical three-phase drive. But we still use silicon carbide (SiC) devices. In our high-voltage inverter, we’re using a standard PCB design and manufacturing methods. Eventually, we’ll get to a bare die construction on the drives.

The circuit is unlike any other drive that’s out there because we’re driving individual coils, so it doesn’t look like a typical three-phase drive.

Charged: What phase of commercialization are you in now? What are the next steps for Exro?

Josh Sobil: Right now, we’re in our launch phase starting in ‘23. We have some early partners that have placed orders for equipment. They want to see samples at the end of this year so they can start to validate into the next year. We’re building a drive manufacturing facility in Calgary and plan to produce drives for commercial and off-highway applications by the third or fourth quarter of next year.

Charged: Do you have any other products in addition to Coil Driver?

Josh Sobil: Fundamentally, the company is focused, obsessed and passionate about power electronics. We are also working on ways to optimize power on the battery side. We’ve developed a battery control system that manages individual cells, very similar to managing individual coils, so it’s taking that granular philosophy and transferring it over to the storage side. It’s in our R&D pipeline, and we’re going through the UL approval process on that storage unit.

This article appeared in Issue 62: Oct-Dec 2022 – Subscribe now.