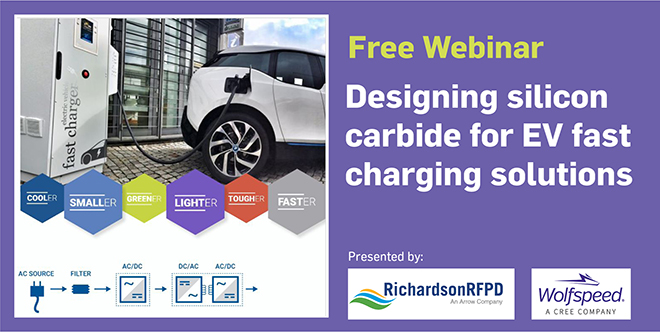

EV fast chargers bypass the vehicle’s on-board chargers (OBCs) for rapid direct battery charging. This allows batteries to be charged in just 30 minutes versus 4+ hours from OBCs. But the demands of these systems are significant. Design goals for fast chargers call for highly efficient power electronics and very high power density that’s possible with the use of wide-bandgap materials.

Wolfspeed’s silicon carbide (SiC) solutions help create smaller, lower-cost, energy-efficient fast chargers. With higher power conversion capabilities, faster switching speeds, and improved thermal performance, SiC is an ideal material to meet the extreme power demands of modern fast-charging stations.

Tune in to this webinar presented by Wolfspeed and Richardson RFPD to learn more about designing SiC solutions for EV fast-charging, including:

- Designing fast charging systems with simpler topologies utilizing Wolfspeed SiC MOSFETs, diodes, and power modules

- Optimizing your system to achieve up to 30% lower losses, 2-3x faster switching speeds, 65% increase in power density, 30% fewer components, and a lower overall cost

- Meeting fast-charging infrastructure requirements, including a 150 kW max for single-car charging, reliability for global environments, and ruggedness for weather conditions

- Addressing the diverse range of voltages and package sizes that EV platforms require

- Reducing time to market and R&D costs with scalable designs

- Achieving higher output power and higher output voltage required by today’s latest 800V and bidirectional battery systems

The webinar was hosted by Charged on July 15, 2020, at 2:00pm EST, and included a presentation and a live Q&A session.