At the upcoming Battery Show North America in Detroit, material handling specialist Coperion will highlight its new K-Tron Loss-in-Weight Roller Feeder, a gravimetric solution for dry electrode coating in battery manufacturing. The new K-Tron feeder is designed to ensure uniform application, enhance process stability, and improve overall efficiency.

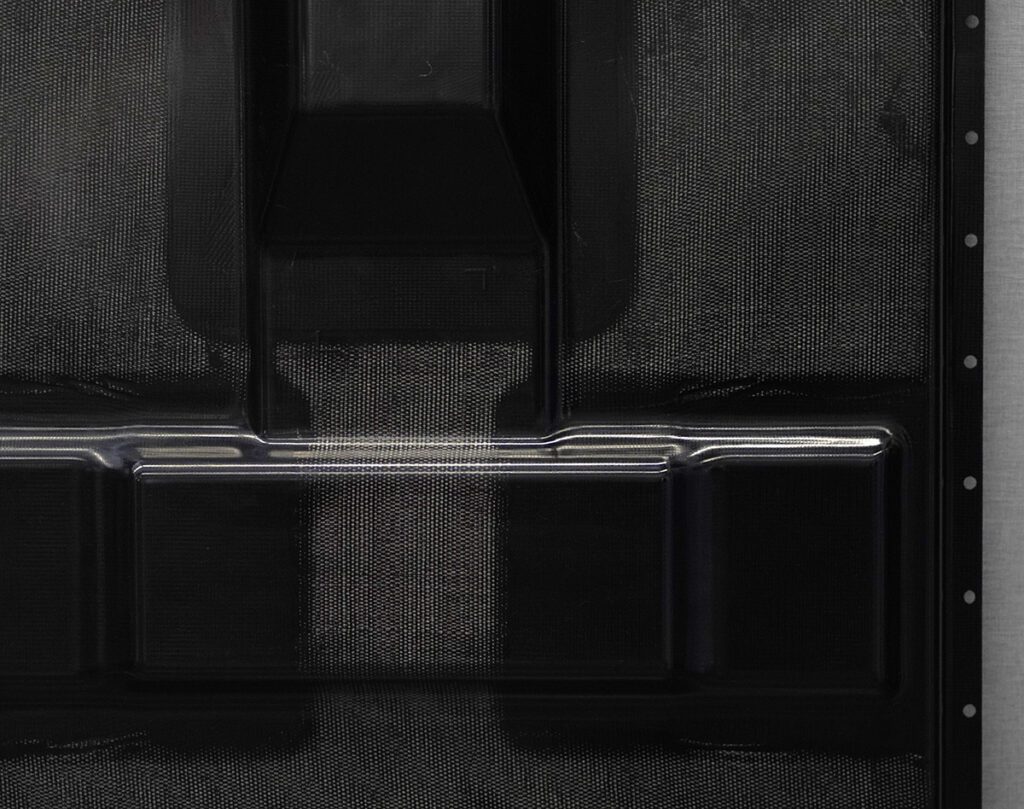

Coperion’s K-Tron Loss-in-Weight Roller Feeder supports continuous feeding of dry electrode coating powder blends directly into the calender gap in dry coating processes. The feeder, which is designed primarily for laboratory and pilot-scale production, is mounted on a robust platform scale that uses highly accurate SFT weighing technology. Its dual roller design, housed within a compact enclosure, features a dynamic feeding gap designed to ensure gentle, consistent material handling while preventing bridging. This ensures uniform and repeatable mass distribution across adjustable widths up to 400 mm.

Coperion’s ZSK extruder, in combination with K-Tron screw feeders, enables continuous extrusion of battery masses in dry coating applications. Its design allows for the simultaneous fibrillation of binders and homogenization of raw materials. The shorter residence time in the extruder, along with precise temperature control of individual barrel sections, allows thermal energy management to be tailored to the specific needs of battery electrode production.

The ZSK twin screw extruder has several features designed to improve the efficiency of electrode manufacturing. Automated operation ensures consistent product flow while reducing space requirements and personnel needs. The ZSK extruder produces highly homogeneous materials, resulting in better product quality even when incorporating difficult-to-mix ingredients, according to the company.

Coperion K-Tron twin screw feeders are designed to ensure accurate feeding of dry electrode materials, such as active powders, conductive additives and binders, which is critical for maintaining quality and consistency in electrode layers. They offer real-time weight measurement, allowing for precise control of material feed rates and minimizing batch variability. They can handle the challenging powder blends and sticky materials that are common in electrode production. By maintaining a steady and accurate material supply, they optimize process efficiency and reduce material waste.

Coperion operates dedicated facilities where customers can test various process steps, including pneumatic conveying, raw material handling and feeding, filtration, and continuous extrusion of battery masses. Supported by Coperion experts, customers can optimize process design to maximize product quality, safety and efficiency. The test centers accommodate all common raw materials and offer extensive simulation and scale-up expertise.

Nick Giefer, Batteries Business Unit Leader at Coperion says, “Our latest innovations, including the Loss-in-Weight Roller Feeder and advanced continuous extrusion capabilities, are designed to improve process stability, material efficiency and scalability in battery manufacturing. These technologies help manufacturers produce high-quality, solvent-free electrodes more sustainably and cost-effectively.”

Source: Coperion