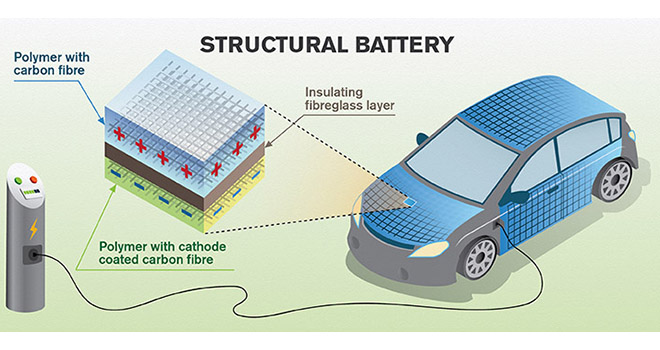

Sweden’s Chalmers University of Technology has been experimenting with carbon fiber as a structural electrode. The team has studied the relationship between carbon fiber’s microstructure and electrochemical capacity, and is working to develop a combination that is both mechanically sound and energy dense. In short, they would like to use an EV’s body as its battery.

The team’s research has discovered that carbon fiber’s electrical and mechanical properties can be carefully controlled by rearranging its graphitic order and crystallite sites. Fibers with small, disorganized crystals have better electrical characteristics with a stiffness slightly greater than steel. Large, highly-oriented crystals provide better stiffness (over twice that of steel), however, the reduction of electrochemical properties becomes too great for practical use as a battery. The team is exploring carbon fiber’s aviation potential as well. They suggest that increasing the composite thickness would overcome the mechanical challenges of structural electrodes while boosting total energy storage capacity.

“The key is to optimize vehicles at system level – based on the weight, strength, stiffness and electrochemical properties. That is something of a new way of thinking for the automotive sector, which is more used to optimizing individual components. Structural batteries may perhaps not become as efficient as traditional batteries, but since they have a structural load-bearing capability, very large gains can be made at system level. In addition, the lower energy density of structural batteries would make them safer than standard batteries, especially as they would also not contain any volatile substances,” says Chalmers Professor Leif Asp.

SEE ALSO: Predicting the properties of lightweight carbon fiber composites

Source: Chalmers via Green Car Congress