Chemical industry giant BASF has added a new product to its portfolio of PPAs (polyphthalamides, a type of thermoplastics). The new Ultramid Advanced N3U42G6, a polyamide 9T with non-halogenated flame retardant, is designed to minimize electro-corrosion of metal contacts in electric and electronics parts for e-mobility. BASF says its new PPA increases the safety and durability of high-voltage connectors in EV components including inverters, DC-DC converters and battery packs.

“Due to its high strength and stiffness over a broad temperature range, its outstanding chemical resistance and dimensional stability, the Ultramid Advanced N grade enhances the robustness and reliability of thin-walled high-voltage connectors, meeting growing industry needs for halide-free components used in warm and humid conditions,” says BASF.

Ultramid Advanced N3U42G6 is available uncolored with UL-certified masterbatches, or pre-colored. It boasts high color stability and excellent color retention after heat ageing.

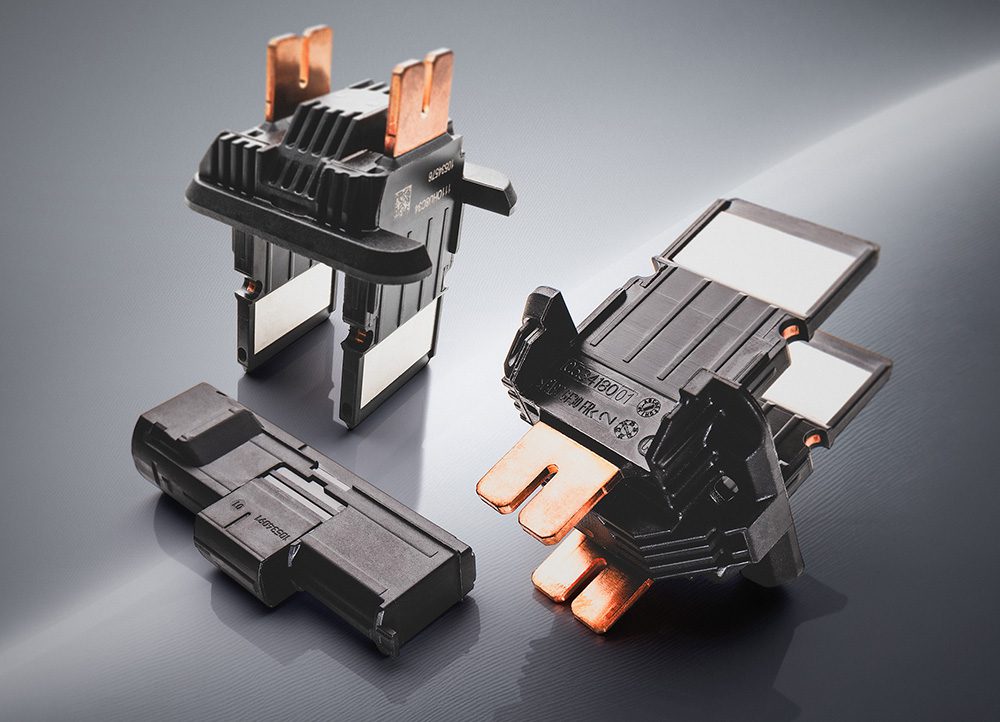

German automotive supplier KOSTAL Kontakt Systeme uses the new Ultramid Advanced N in several components in its high-voltage connector KS22 Class 4 for high-current modules. The company’s HV-connector, the smallest in its performance class, benefits from the BASF PPA in several ways: the new PPA enables miniaturization and saves installation space, as it shows good flowability at thin wall thickness; it provides the connector with very high electrical insulation—superior to that of aliphatic polyamides, especially at elevated temperatures. Finally, it has a high elongation at break so that there is no stress whitening when the different components are mounted.

Ultramid Advanced N3U42G6 is halide-free (according to EN 50642), so it prevents contact corrosion and extends the lifetime of electrical and electronic components. The PPA achieves fire protection class UL94 with V-0 at 0.25 mm. It also enables long-lasting color coding—in in-house tests, color stability was confirmed after 1,000 hours at temperatures of up to 150° C.

“Our new non-halogenated grade combines the excellent properties of our superhero Ultramid Advanced N with better colorability, long color stability and outstanding anti-corrosion effect,” says BASF’s Volker Zeiher. “With this optimized PA9T, our customers can develop innovative, best-in-class components supported by BASF’s proven flame-retardant expertise and material know-how for electronics manufacturing.”

Source: BASF