German chemical company BASF has started the commercial operation of its battery black mass recycling plant in Schwarzheide, Germany. The facility has an annual processing capacity of up to 15,000 tons of end-of-life lithium-ion batteries and production scrap. This is equivalent to 40,000 electric vehicle batteries per year. The black mass contains high amounts of… Read more »

Search Results Found For: "BASF"

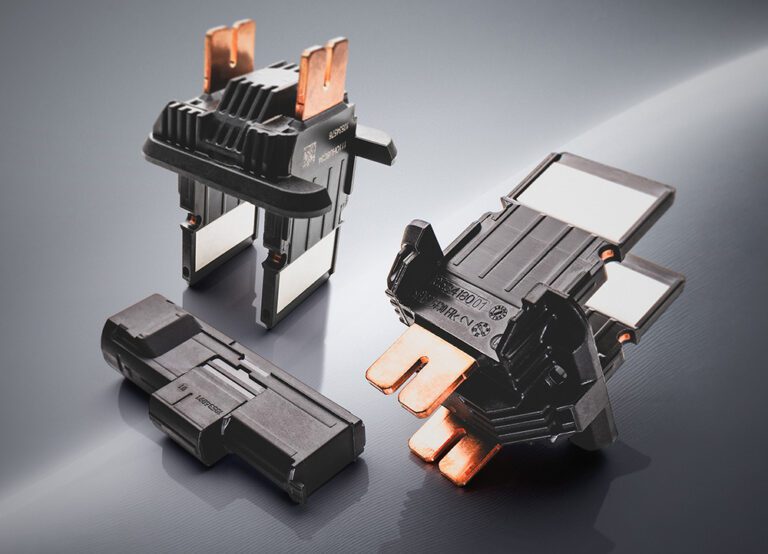

BASF’s new Ultramid Advanced N for high-voltage connectors in EVs boasts reduced corrosion

Chemical industry giant BASF has added a new product to its portfolio of PPAs (polyphthalamides, a type of thermoplastics). The new Ultramid Advanced N3U42G6, a polyamide 9T with non-halogenated flame retardant, is designed to minimize electro-corrosion of metal contacts in electric and electronics parts for e-mobility. BASF says its new PPA increases the safety and… Read more »

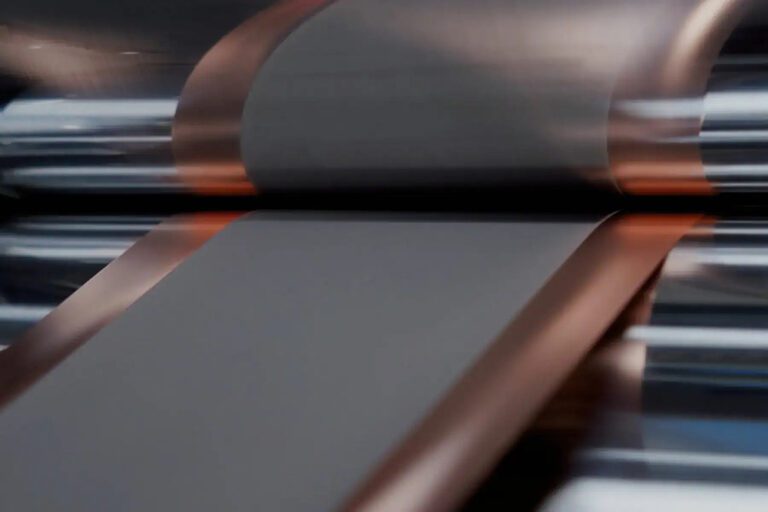

BASF and Group14 collaborate on silicon anode battery durable at extreme temperatures

German chemical manufacturer BASF and US silicon battery materials manufacturer Group14 Technologies have collaborated on a market-ready silicon battery solution using commercially available materials: BASF’s Licity 2698 X F binder and Group14’s silicon battery material, SCC55. BASF and Group14 claim they have developed a drop-in-ready solution that enhances the performance of batteries with silicon-dominant anodes,… Read more »

BASF scales up US manufacturing of anode binders for EV batteries

German chemical manufacturer BASF has expanded its manufacturing capabilities in the US to include the production of Licity anode binders for EV batteries. With this new production capability, BASF now offers its Licity portfolio across all regions. The company said it anticipates access to local supply of raw materials as well as global availability to… Read more »

BASF unveils new PPA housing material for IGBT semiconductors

The world’s largest chemical producer, Germany’s BASF, has developed a polyphthalamide (PPA) for manufacturing housings of insulated-gate bipolar transistor (IGBT) semiconductors for next-generation power electronics. The Ultramid Advanced N3U41 G6 is designed to meet the growing demand for high-performance, reliable electronic components for EVs, as well as high-speed trains, smart manufacturing and renewable electricity generation…. Read more »

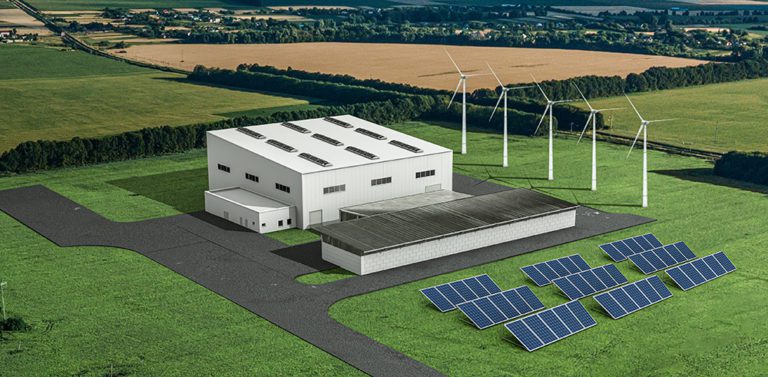

BASF begins operations at prototype metal refinery for EV battery recycling

Chemical producer BASF has started operating its prototype metal refinery for battery recycling in Schwarzheide, Germany. The plant is focused on the development of operational procedures and the optimization of battery recycling technology, processing end-of-life lithium-ion batteries and battery production scrap. This will facilitate the optimal recovery of metals such as lithium, nickel, cobalt, manganese… Read more »

BASF offers engineering plastics for EV motors

German chemical manufacturer BASF offers a portfolio of engineering plastics that can be used in co-creation partnerships with the automotive industry to develop next-generation EV motors. The compounds are available in different colors, from colorless to orange and laser-markable black, and feature short-glass, long-glass or mineral fiber reinforcement as well as various heat stabilizers. The… Read more »

BASF establishes a co-located battery material production and recycling center

BASF, a chemicals firm, has opened a battery material production and recycling site in Schwarzheide, Germany. The automated production plant makes cathode active materials, and mechanically processes end-of-life batteries and battery production waste for the production of black mass, which contains lithium, nickel, cobalt and manganese. The factory will provide European cell manufacturers and automotive… Read more »

BASF to build black mass plant in Germany to recycle batteries

BASF has announced it will build a black mass plant for recycling batteries in Schwarzheide, Germany, where it already has a cathode active materials production and recycling facility. The company says the new plant, which is expected to begin production in early 2024, will be built to the highest environmental, health and safety standards. BASF… Read more »

BASF introduces a new rubber binder for silicon anodes

BASF has introduced a new rubber binder designed for anodes, part of the company’s Licity product line. Licity 2698 X F is a styrene-butadiene rubber binder for anodes that have more than 20% silicon. The company says it has “excellent stress-strain properties and elasticity.” “Hurdles such as low range and long charging times can be… Read more »