Battery manufacturer Amprius has demonstrated a new system for inline, continuous, and roll-to-roll production of three-dimensional silicon nanowire anodes that it says will enable it to scale up manufacturing more quickly.

Silicon is widely considered to be the next big thing in anode technology – battery-builders and automakers (including Tesla) are working on ways to take advantage of its high theoretical charge capacity.

According to Amprius, its batteries, with silicon anodes, achieve significantly higher energies per unit volume (800-1,000 Wh/L, depending on cell capacity and form factor) and per unit weight (325-400 Wh/kg) than today’s commercially available carbon-anode designs.

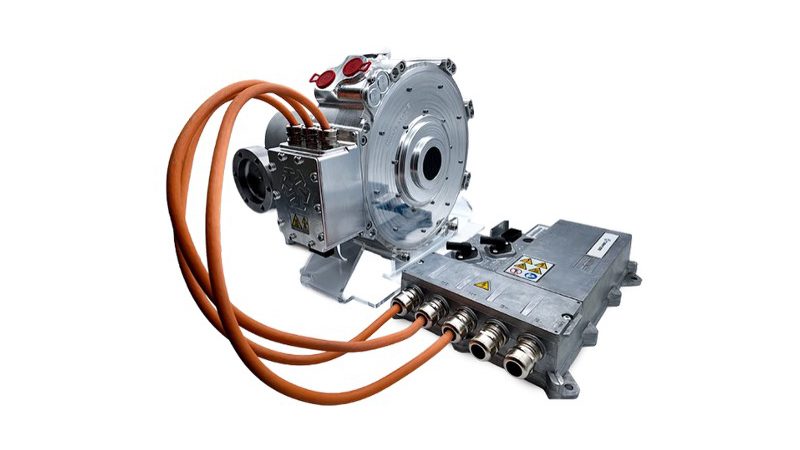

The new manufacturing tool, which Amprius developed in partnership with the Dutch firm Meyer Burger, uses a multi-step Chemical Vapor Deposition (CVD) process to produce Amprius’s silicon nanowire anodes.

“Inline, continuous, and roll-to-roll manufacturing will enable Amprius to transition high-energy batteries from lab to market, and from batch processing to pilot production,” said Dr. Kang Sun, Amprius CEO.

“Amprius’s manufacturing demonstration is a very big step forward,” said former Secretary of Energy and Amprius Board Member Steven Chu. “In recent years, Amprius’s silicon anode technology has enabled batteries with ultra-high energy. This year, Amprius’s new tool is a significant advance towards high-volume and high-quality manufacturing.”

Source: Amprius