Few have been working on human-machine interface (HMI) design for EV drivetrains as long as Brian Gallagher and Kevin Coelho. In 2007, Gallagher joined the startup Aptera Motors as employee number three. Shortly after, Coelho joined him as the seventh addition to the California company, which was building ultra-efficient three-wheeled electric vehicles. Five years later, in 2012, after peaking at over 100 employees, Aptera closed its doors.

That’s when Gallagher formed Andromeda Interfaces. The company provides instrumentation hardware and interface integration design to the growing market of specialty EV OEMs. “The growth of consumer EVs has been phenomenal,” Gallagher told Charged. “But there are also many niche OEMs that are adopting the technology in parallel.” The spread of lithium battery technology across specialty vehicle segments has created a great opportunity for suppliers like Andromeda to share their expertise. Emerging segments include applications like materials handling, delivery, transit, mining, construction, off-road utility, e-motorcycles, and small vehicles like golf carts and NEVs.

Trees, leaves and butterflies

There are some important display parameters that obviously don’t change when switching from gas to electric – the vehicle’s speed for example. However, EVs present new challenges that aren’t so obvious to a specialty OEM designing an electrified vehicle for the first time. In fleet applications, minimizing the learning curve is critical to safe and efficient operation.

The silent operation of an EV when first powered up, for instance, can take some getting used to. If a new driver of a delivery or transit vehicle is confused about the mode of operation, bad things could happen. Andromeda urges its fleet customers, particularly those with high operator turnover, to design EV driver interfaces with prominent symbols and sounds that indicate when a vehicle is first turned on and/or yet to be turned off.

Efficient operation is also far more important in EVs than in traditional vehicles. For the foreseeable future, the technology bottleneck for EVs will continue to be the cost and limited energy storage capacity of lithium-ion batteries, so it’s important to get the maximum range for the available energy. However, Andromeda explains that the design process for an intuitive interface that encourages efficient and safe driving habits is very complex due to all the variables that need to be considered.

“We spent a lot of time and effort at Aptera learning how to measure our efficiency accurately and then provide those metrics to the driver,” said Gallagher. “But in the end, it seemed like nobody ever cared about the data on instantaneous efficiency during driving. It didn’t provide any value to the driver at all. In fact, some found it to be a bit of a distraction.

” The Andromeda team explains that, while engineers love to “geek out” on data, only a small fraction of drivers respond to it. They found that both instantaneous efficiency and average efficiency over time is not that valuable to drivers in terms of altering behavior. Many consumer hybrids and EVs have attempted to bridge this data-to-driver gap with creative graphical interfaces that change with your driving efficiency – trees that sprout leaves is one commonly used theme. But Andromeda believes the problem is that drivers lack the ability or know-how to change behavior.

“The data becomes relevant and effective only if the operator has the ability to change something,” said Gallagher. “For the most part, we believed that efficiency data should be processed internally to try to come up with ways to improve it. Then, whenever possible, the system should provide suggestions back to the driver or operator. As an engineer designing the system, we’re very conscious of efficiency and trying to optimize it. But when you get behind the wheel, that tends to go out the window when you realize how fun EVs can be to drive.”

Andromeda urges designers to focus on finding effective ways to communicate suggested changes in behavior, and how the choices could translate into usable driving range and fuel consumption. The goal is take full advantage of EV technology by providing the right information to drivers, to encourage behaviors like dialing down the HVAC systems or switching to “eco” driving modes to reduce energy consumption. “In the end, the data doesn’t mean anything if you don’t adapt,” said Gallagher.

Design considerations

Andromeda walked us through some of the most common EV HMI design considerations and what they recommend to their specialty OEM customers.

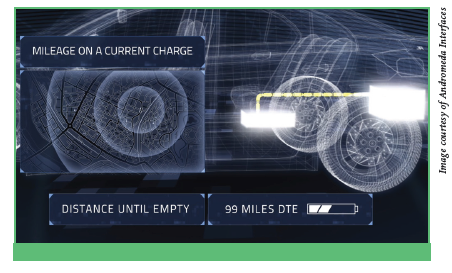

Distance to empty (DTE):

- Confusion: If users do not understand how DTE is dynamic due to driving methods in an EV, they will often be confused by a rapidly shifting parameter.

- Solutions: DTE can be represented in a simple dial gauge with the miles-to-zero range. It can also be shown dynamically with a shrinking or expanding circle on a map representing the current available range. It’s most commonly displayed as a horizontal meter combined with text – e.g. “50 miles to empty.” In any case, DTE calculations that change quickly with regard to driving patterns should be avoided.

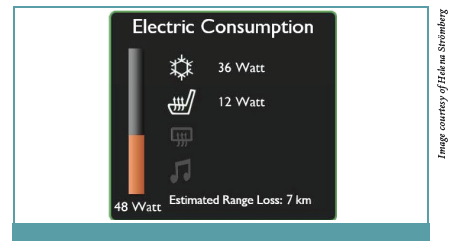

Auxiliary load (electricity consumption):

- Confusion: What is an auxiliary load? Which are the major contributors to energy loss?

- Solutions: It’s important to be precise when reporting the particular auxiliary load that is consuming energy. This can be done using common symbols for each load: a chair for heated seats, a music note for the stereo, a snowflake for HVAC, etc. Combining symbols, text descriptions and exact values for consumption will help to fully convey the losses that are due to each load.

Tell-tales and warnings:

- Confusion: In addition to minimal noise at start-up, the possible problems with an EV drivetrain will differ from those of conventional vehicles. Developing new tell-tales, indicators or signals is necessary to convey what maintenance may be needed.

- Solutions: A recognizable tell-tale needs to be clearly visible when the vehicle is powered on, in order to deliver the important “power on” message. Other maintenance or fault warnings need to leverage symbols that are meaningful to the average person. Combine symbols with text descriptions whenever possible.

State of health (SOH):

- Confusion: The SOH, or reduced storage capacity, of the battery pack is not easily understood because many people don’t realize that batteries degrade over time.

- Solutions: Consider showing the SOH as the vehicle gets older and indicate how this could potentially impact the EV’s performance over time.

Regenerative braking:

- Confusion: The concept of regenerative braking can be difficult to understand, and encouraging proper use is critical to increasing range and significantly improving the life of the friction braking system.

- Solutions: The regenerative braking force can be harsh or gentle depending upon the amount of motoring current allowed. Consider offering a rotary dial in the cabin to easily adjust regenerative braking. Drivers often need to experience this force first-hand, so give them the opportunity to dynamically adjust to a high default setting that maximizes the benefits of the system.

EVIC

To help engineers at the specialty OEMs cope with the new streams of data, Andromeda developed a customizable software and hardware display solution for EV systems that it calls Electric Vehicle Interface Controller, or EVIC. “It’s designed to collect and interpret the data coming from all key components that make up the electric drivetrain – the motor, controller, battery management system, charger, etc,” explained Gallagher. “Depending upon the specific target market, how that info is displayed to the driver is unique, which is why we designed it to be configurable.”

The company’s unique proposition is that its system will interface and gather data from all of the most popular electric drive systems on the market. “That’s our best selling point to customers – we know how to combine the data from many different devices,” said Gallagher.

As the world continues to transition vehicles of all shapes and sizes to battery power, Andromeda recognizes the importance of creating a nimble solution that can fit into many different niches. “The goal is to be the global leader for EV instrumentation. There are many segments of the market, and we’re dabbling in all of them.”

This article originally appeared in Charged Issue 19 – May/June 2015.