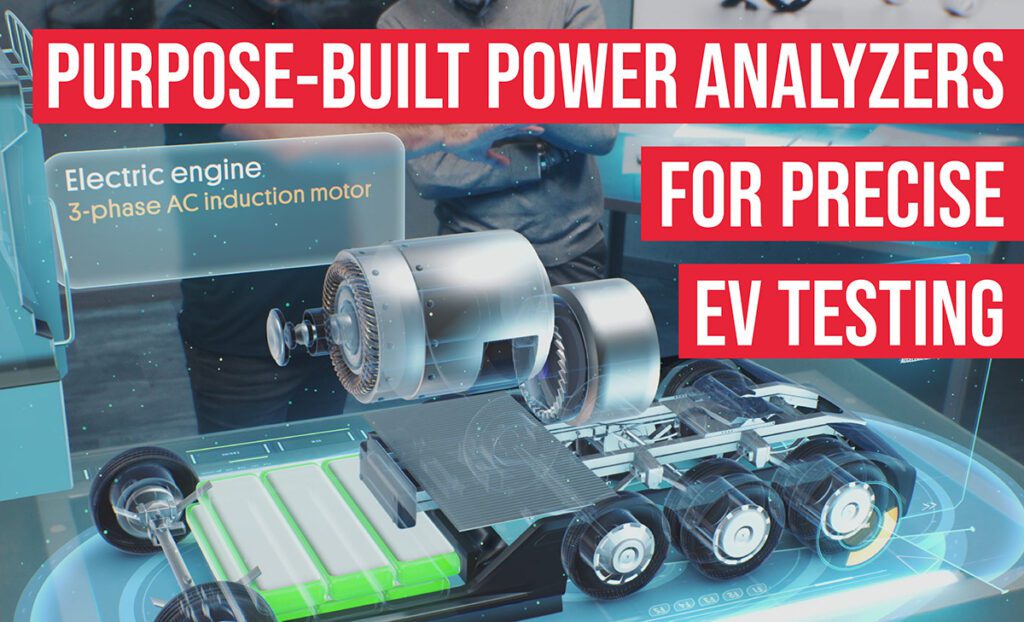

ANSYS’s new release enables engineers to blend system simulation with a computational fluid dynamics approach.

We’re not suggesting that EVs should don a pair of bunny ears and a bass drum, but for electric cars to truly break through as the prevailing mode of transportation, they need to keep going, and going, and going. Whether or not typical driving habits justify it, fear of fizzling out, aka range anxiety, plays a major role in the public’s hesitance to accept pure EVs into their hearts and garages. Also starring in the EV no-show: cost. Simple economics drives prospective EV owners back home toward ICE-running vehicles with predictable regularity.

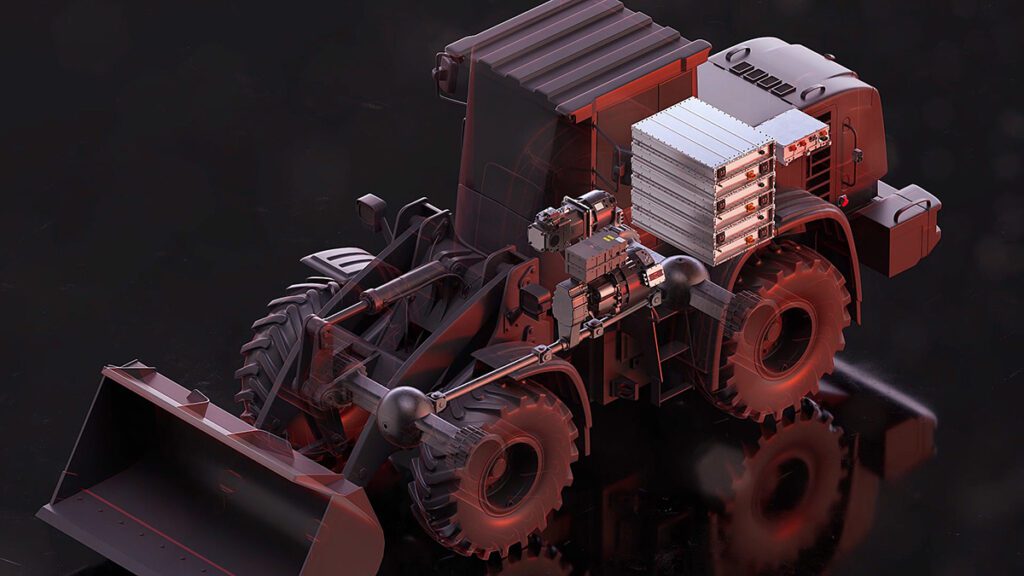

At least we know that in both cases of EV cost and EV range, the most direct route to salvation goes through the battery pack. A less expensive, more energy-dense battery represents the Holy Grail of a thousand technological pilgrimages. Yet the “game-changers” promised in press releases and industry events always seem to be years away from commercialization, a common theme related to the notoriously laborious battery-making process.

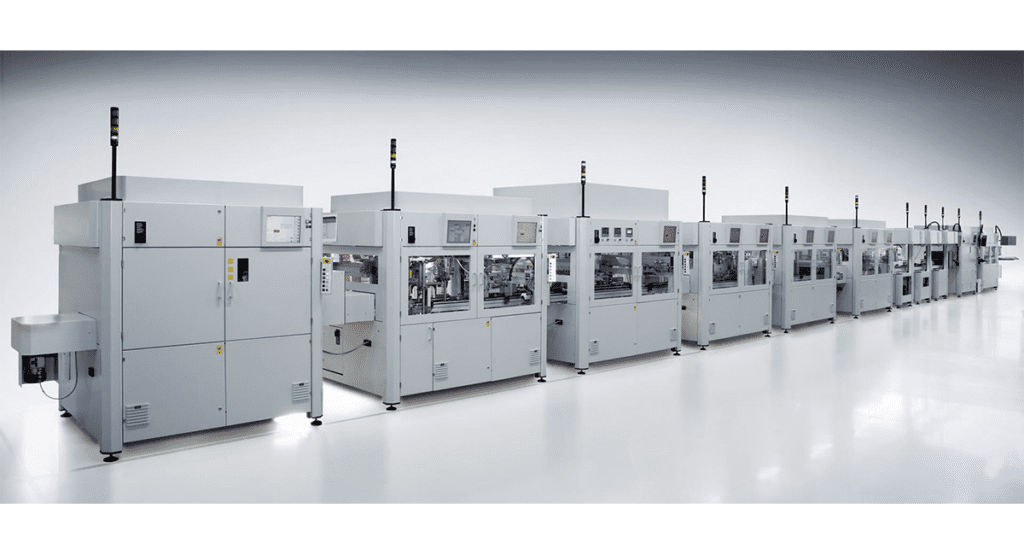

The headaches caused by range anxiety cry out for more immediate relief. Well, take these two battery innovators and call us in the morning. Both ANSYS, Inc. and Wildcat Discovery Technologies use very different techniques to build better batteries faster. The former company deals in computer simulations, while the latter claims its proprietary systems can synthesize new energy-storage materials up to 100 times faster than standard labs.

The soft cell

In 2010, the US Department of Energy (DOE) launched the Computer Aided Engineering for Electric Drive Vehicle Batteries (CAEBAT) program to promote design and simulation tools for battery development, because such tools were not as advanced and accepted as they were for conventional vehicle parts. The National Renewable Energy Lab (NREL) took charge of the program seeking simulation technology for maximizing electric vehicle battery output.

ANSYS teamed with General Motors and ESim to win a key award from NREL under the program. The 2,000-strong CAE simulation software company – out of Canonsburg, Pennsylvania – would contribute existing and newly developed battery modules to the CAEBAT project that can simulate battery performance both at the individual cell level and for an entire battery pack. ANSYS’s modules aim to shorten design cycles while addressing not only battery cost and energy density, but also life cycle, operating temperature, and safety.

ANSYS teamed with General Motors and ESim to win a key award from NREL under the program. The 2,000-strong CAE simulation software company – out of Canonsburg, Pennsylvania – would contribute existing and newly developed battery modules to the CAEBAT project that can simulate battery performance both at the individual cell level and for an entire battery pack. ANSYS’s modules aim to shorten design cycles while addressing not only battery cost and energy density, but also life cycle, operating temperature, and safety.

ANSYS is an engineering simulation software provider and developer in the area of CAE, bringing together mechanical, electrical, chemical, and aerospace engineering into the common theme of virtual assessment of product performance. It also provides services for supporting the software, consulting with the software, and training people on the software. Its targeted program of collaborative R&D has ANSYS working with other companies, government labs, and academics to attack technical problems in many areas, batteries being one of them. The ANSYS mission is simulation-driven product development and design, focused on systems-level engineering in multiphysics.

“You need to keep the big picture in view when you’re designing complex systems,” says Lewis Collins, Development Director at ANSYS. “If you’re just developing things on the component level, and you put all those components together – like in electronics – , you can have a lot of problems.”

That was one reason for the DOE’s CAEBAT program in the first place: to reduce the problems of component-level battery development. “What [the DOE] found is that there’s a lot of trial and error in battery design,” Collins says. “We use simulation as a really intelligent way to cut down on that sort of blind, trial-and-error development. The DOE could see that existing tools out there didn’t have the capabilities needed to scale up and optimize batteries for electric vehicles. So they incentivized the software providers to fill in those gaps, as well as to make the tools easier to use and more effective for battery design studies.”

A tale of two sims

After a little more than a year into a three-plus-year project, the CAEBAT team has developed and validated three electrochemistry modeling methods and a simulation prototype that blends two ANSYS specialties – systems-level simulation and multiphysics – for batteries. ANSYS will gradually release new CAEBAT-related tools to the project partners and that will eventually result in a commercial version. While still in the first round of developing, validating, and enhancing these tools, according to Collins, there are already some features in beta that should be commercially available by the end of 2012.

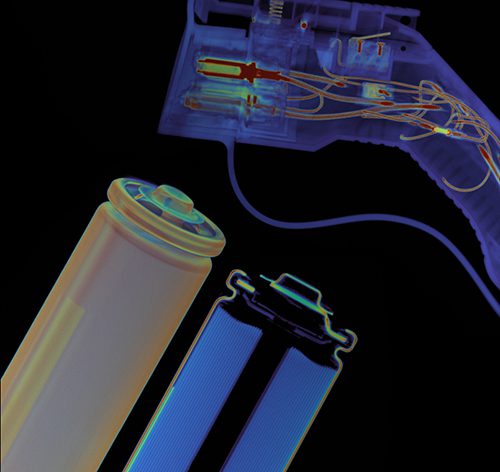

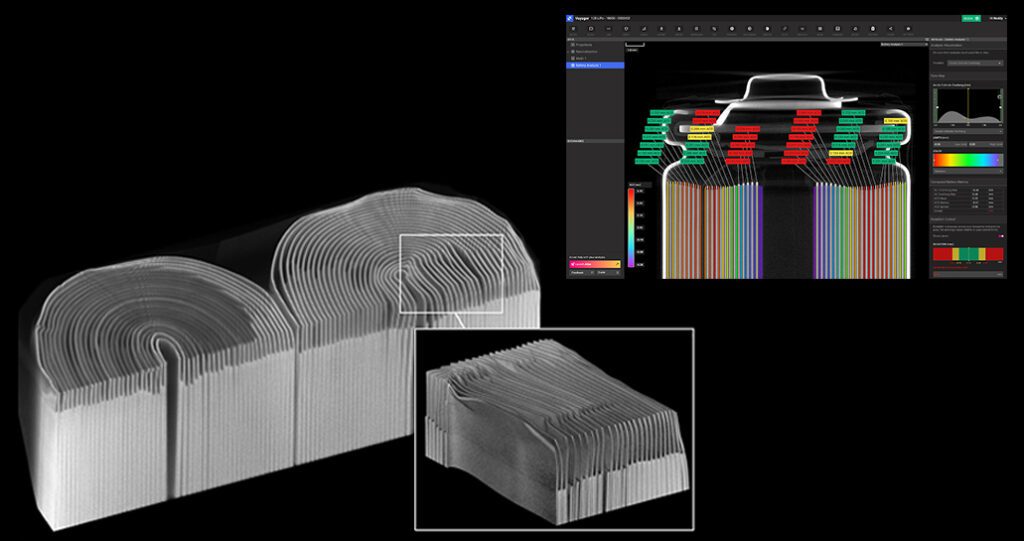

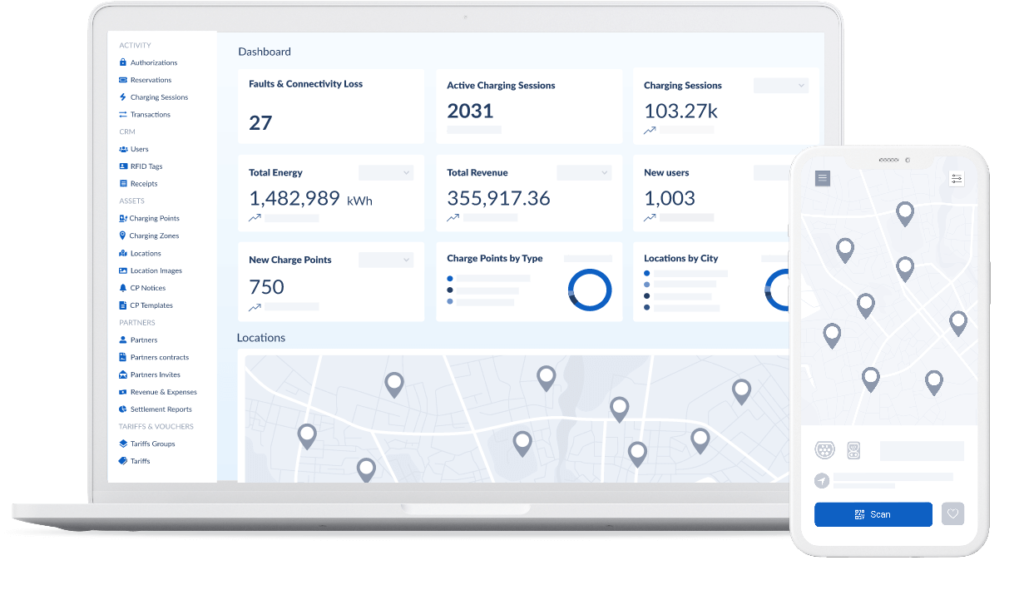

That release enables engineers to blend system simulation with a computational fluid dynamics (CFD) approach. Collins says, “in the traditional lumped-parameter system approach, one battery cell might be a node in an electrical circuit diagram. The problem was, CFD was very rigorous and gave you great detail of the temperature patterns, and system simulation was not so rigorous, but was much faster. What we’ve done is blend the two together and create what we call a co-simulation link. You can actually run them both at the same time, and you can selectively use the high-fidelity method and then embed that into the system model to have the best of both worlds.”

That release enables engineers to blend system simulation with a computational fluid dynamics (CFD) approach. Collins says, “in the traditional lumped-parameter system approach, one battery cell might be a node in an electrical circuit diagram. The problem was, CFD was very rigorous and gave you great detail of the temperature patterns, and system simulation was not so rigorous, but was much faster. What we’ve done is blend the two together and create what we call a co-simulation link. You can actually run them both at the same time, and you can selectively use the high-fidelity method and then embed that into the system model to have the best of both worlds.”

According to Collins, battery researchers are an ideal target for this new approach, because there may be hundreds or even thousands of cells in a battery pack. “They would like to look at maybe one cell or a ‘worst-case’ cell with CFD,” he says, “but they can’t afford to do that. They really need the system-level modeling for the pack.”

According to Collins, battery researchers are an ideal target for this new approach, because there may be hundreds or even thousands of cells in a battery pack. “They would like to look at maybe one cell or a ‘worst-case’ cell with CFD,” he says, “but they can’t afford to do that. They really need the system-level modeling for the pack.”

ANSYS joined CAEBAT despite having no software products that specifically target batteries, nor does it plan to make such a product.

“That may be surprising to some people,” Collins says, “but really the secret of ANSYS’s success has been figuring out what’s the root engineering and simulation that needs to be done, and what’s the commonality between batteries, electronic circuits, internal combustion engines, and all the different applications that can be provided in a way that’s useful to a lot of people. Having said that, we also have ways to tailor or verticalize some of our general tools to make them easier and more automated for batteries. There’s this balance between the generic and highly verticalized software that we’re pursuing. One of the ways we do that is to utilize the scripting and user-programming capabilities of our products, to quickly create a ‘killer app’ for predicting battery performance.”

The core of ANSYS’s product suites is called ANSYS Workbench™, and the company’s other products are based on it and connected to it. For example, there’s ANSYS Mechanical™ for structural analysis, ANSYS Fluent® for fluid flow and thermal analysis, ANSYS Simplorer® for systems-level simulations, and many others. ANSYS was attractive to the DOE as a player in CAEBAT because these general-purpose software tools are already in widespread use, backed by ANSYS expert support, at most of the world’s major automotive, battery, and electronics companies.

Collins explains, “battery breakthroughs are going to require research and development involving several disciplines and scales. For example, if you’re interested in thermal, you might have thermal stress concerns, or on the other hand, you might be interested to drill into the electrochemistry inside the battery. If you’re interested in the very coarse-grained, pack-level results as opposed to a very fine-grained result inside an individual battery electrode, we have tools to do really the whole spectrum.”

Within the CAEBAT project, Collins says, “we’re driving the core products forward in ways that are necessary to handle the right physics for the batteries, and also trying to customize them in a very targeted way for batteries, with scripting and programmability.”

For CAEBAT, the DOE is not focusing on molecular-level simulations that materials scientists looking for different electrode compounds may be interested in. And that is not what ANSYS does, either. “We are focused on macroscopic design,” Collins says. “How you would lay out the individual stack of electrodes and how you would package it in its cell. Further, how you would cool those cells and package those in a module or a pack for an electric vehicle.”

With its current suite of tools and those that it is developing through CAEBAT, ANSYS expects to predict most of the important factors for automotive batteries, including volume, weight, energy density, optimal operating temperature, lifetime, and safety concerns, such as reaction to crash events and electrical abuse. They can also simulate a drive cycle and a pulse charge or discharge.

The one thing ANSYS software does not directly predict is cost, but that factor will come as part of the larger collaborative project. Collins explains that overall, CAEBAT is asking “how can we make better performance batteries and at the same time bring the cost down to where it’s really competitive in the marketplace when they put them in electric vehicles?”

As ANSYS incrementally releases its simulation software resulting from the CAEBAT project over the next couple of years, we’ll begin to see just how useful and cost-effective it can be to model high-tech products like batteries in order to speed up development.

Meanwhile, software simulation will be racing against real-world rapid materials synthesis to see which method reaps the largest gains in battery development.

Accelerating battery development: part 2 – Wildcat Discovery Technologies >