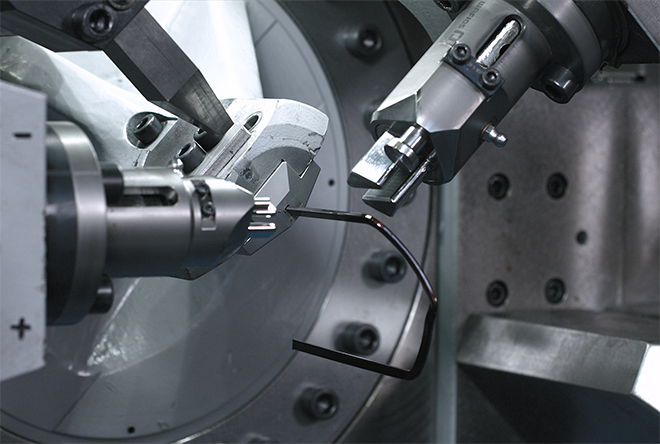

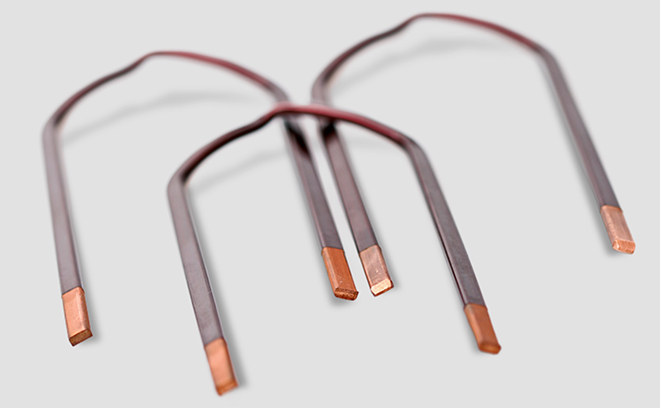

WAFIOS has introduced the SpeedFormer, a new approach to the production of hairpins for electric motors, which unites three wire and tube bending techniques into one system.

WAFIOS modified and optimized a previously used technique for simple hairpin bends in order to improve production speeds.

The company developed and patented a second bending technique, based on the rotary-draw method used in tube bending machines. It is used for making complicated bends with overlapping geometry elements as they occur at the head of hairpins (i.e. S shapes). This new technique is designed to improve bending qualities and continuous process reliability as the processed material is actively clamped during the bending process.

In the twisting process—the third of the three techniques—the feed unit is rotated in such a way that a defined twist of the hairpin legs can be produced.

WAFIOS says the SpeedFormer reduces series production cycle times from 6-10 seconds per hairpin to 1-1.5 seconds per hairpin.

Also, the hairpins are programmed based on their geometry. The operator enters the bending angle, leg length and twisting angle into a table in the order specified by the geometry of the hairpin. Based on this table, the system automatically calculates the axis movements in real-time.

Source: WAFIOS