Ensuring circuit survival in the challenging automotive and electric vehicle environments.

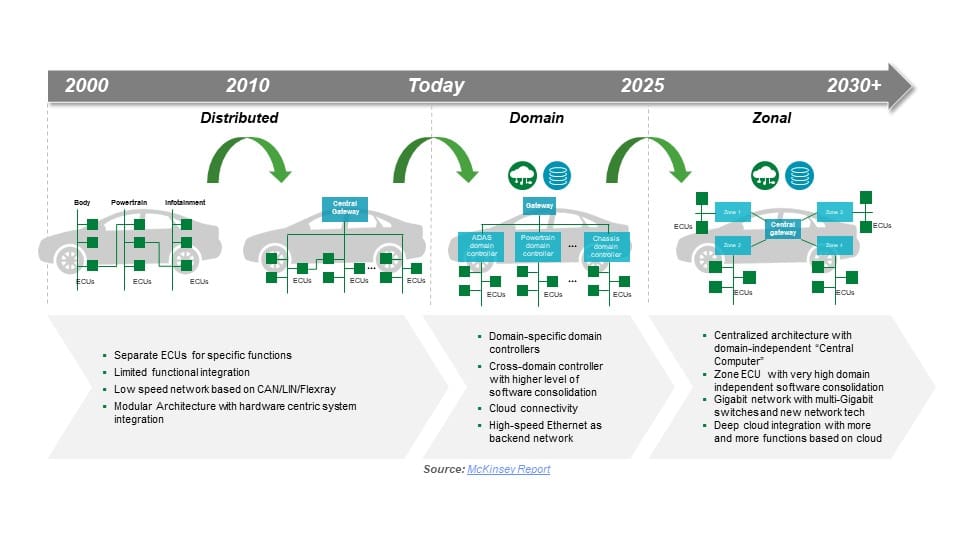

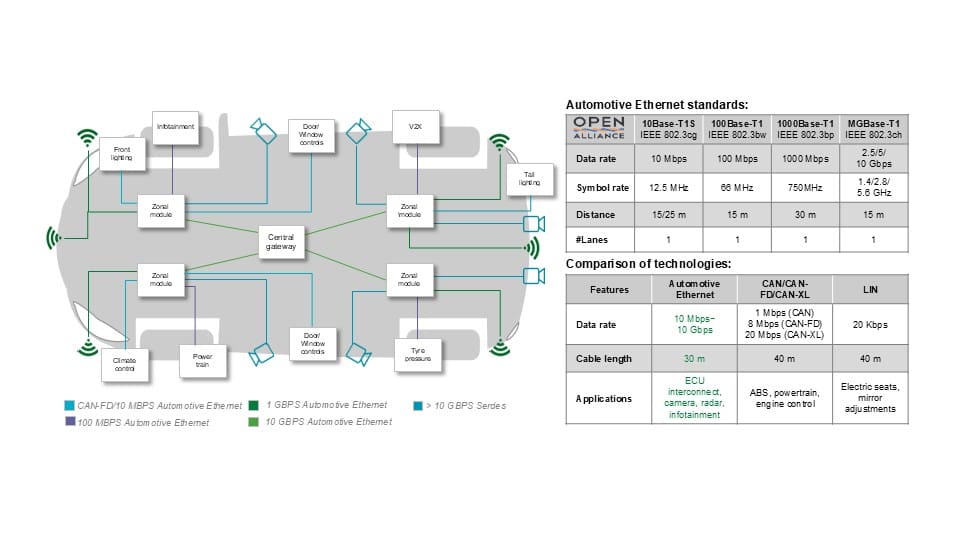

As vehicle electrification grows and adds functions, the electronic control architecture must evolve to manage operations efficiently, responsively, and safely. The architecture is shifting from a simple distributed system to a zonal control system, where zonal control units manage nearby ECUs, simplifying wiring and reducing vehicle weight. Automotive Ethernet is the main protocol for zonal control.

The zonal control unit is crucial for the entire vehicle, requiring robust protection against overcurrent, transient voltages, and ESD. Protecting Ethernet lines ensures reliable communication and data integrity. This article guides designers in selecting components to safeguard zonal controller circuits and communication lines, enhancing automotive electronics‘ reliability.

The evolution of automotive control architectures

Automotive architectures must adapt as automobile electrification grows. High-end vehicles may now have up to 150 ECUs, with features like autonomous driving adding more complexity. The rising number of ECUs strains the distributed control architecture, where each ECU communicates via a central gateway, creating bottlenecks.

To ease these demands, a domain structure was developed, grouping common functions like powertrain and lighting under domain controllers. However, this can complicate wiring due to the distance between functions.

The advanced zonal control structure uses zonal control units to manage functions within specific vehicle zones, enabling more software-defined functionality. Zonal control offers several benefits:

- Reduces wiring complexity and total wiring.

- Enhances modularity and scalability, allowing changes without affecting the entire vehicle.

- Enables faster, more efficient coordination through high-speed Ethernet.

- Improves response times, energy efficiency, and safety with distributed processing power.

Zonal control units must withstand electrical hazards like overcurrent, overvoltage transients, and ESD to remain operational. Adding appropriate protection components to the circuitry ensures robust performance.

Zonal Control Unit (ZCU) Description

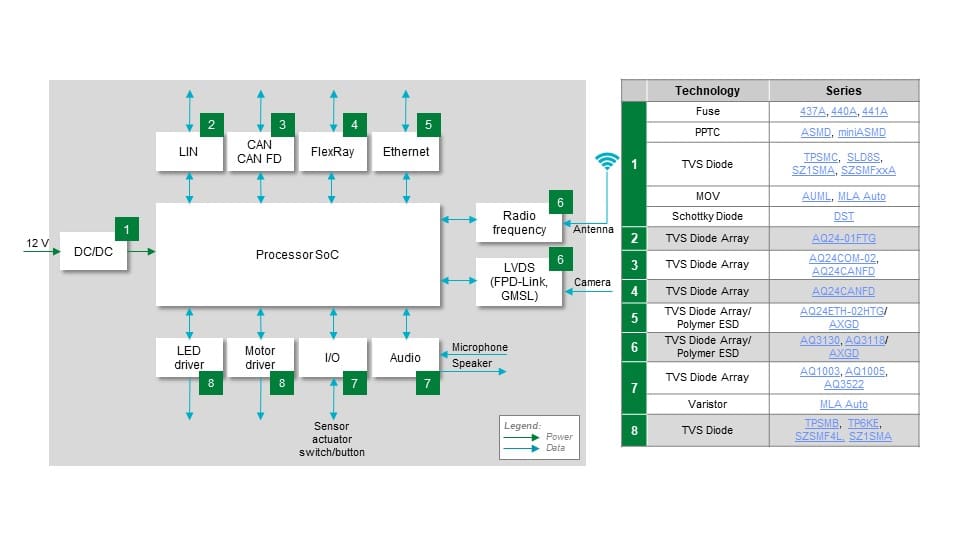

The ZCU interfaces with all types of devices in its zone of control. Thus, it can use many different types of communication protocols to interface with a wide range of devices. Figure 2 illustrates the circuit blocks of a ZCU. Hazards that could damage the ZCU include overcurrent conditions, transient voltages, and particularly ESD.

Protecting the DC/DC Converter

The DC/DC Converter down-converts the 12 V input to digital logic voltage levels. Since the DC/DC Converter is the power entrant to the ZCU, preventing damage from an overcurrent condition and keeping voltage transients out of the circuit is essential for reliable operation.

Either a one-time fuse or a resettable fuse can provide overcurrent protection. Consider a fast-acting, one-time fuse. Versions can open in less than 5 s to a 250% overload. A wide temperature range is essential for automotive applications. Fuses rated from -55° C to +150°C are available. To save space, select a surface mount fuse, which can be in a small 1206 package. Also, choose AEC-Q200-qualified components for automotive applications whenever possible.

A polymer positive temperature coefficient (PPTC) resettable fuse is an alternative to the one-time fuse. A benefit over a single-shot fuse is that PPTCs are resettable. Once the overcurrent condition has cleared, the PPTC will return to a low-resistance state and reconnect the power to the circuit. AEC-Q200 versions are available and come in space-saving surface-mount packages.

For voltage transient protection, particularly against inductive transients such as inductive energy discharges, either a metal oxide varistor (MOV) or a transient suppressor diode (TVS) can safely absorb their energy. MOVs:

- Can absorb load dump energy up to 25 J as required by SAE specification J1113

- Have a wide operating temperature range from -40° C to +125° C

- Are AEC-Q200 compliant.

The alternative component, models of TVS diodes, offer:

- ESD protection to strikes as large as 30 kV in accordance with IEC 61000-4-2

- Absorption of peak power pulses up to 1500 W or surge currents up to 200 A

- Response times from under 1 ps to under 1 ns

- A wide operating temperature range of -65° C to + 150° C

- Uni-directional or bi-directional models

- Surface mount packaging

- AEC-Q101 qualification.

Protecting the DC/DC Converter from overcurrent and transient voltage surges prevents these hazardous conditions from propagating to downstream circuits, ensuring the ZCU processor is shielded from damaging energy.

Protecting the ZCU interface circuits

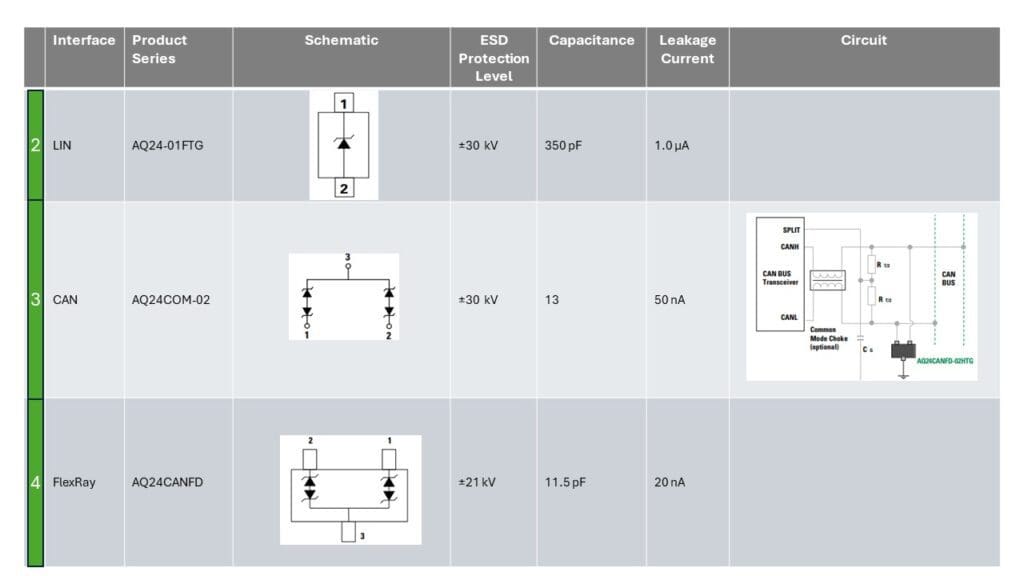

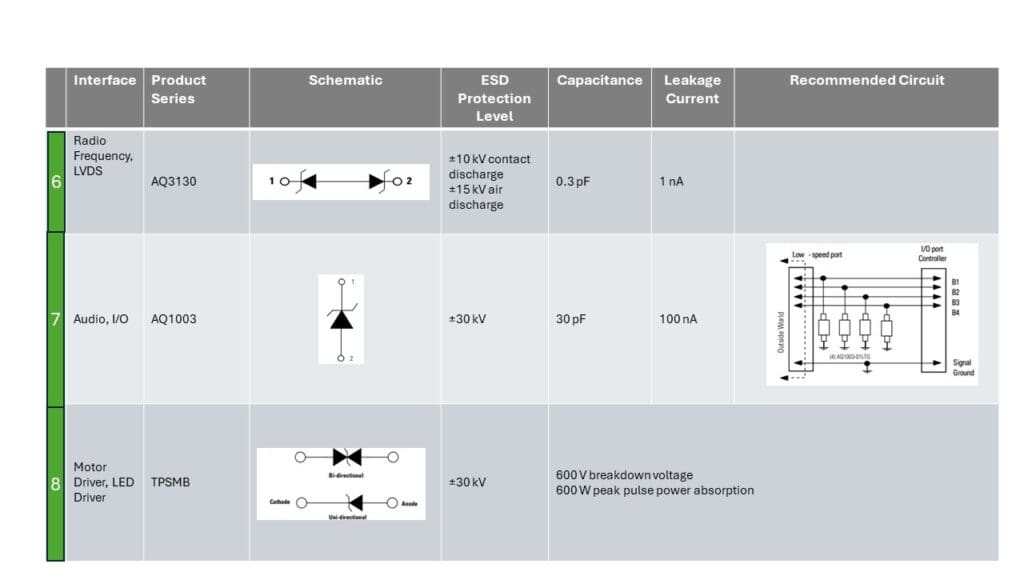

In the high-noise, high-transient automotive environment, ZCU circuits interfacing with external devices via communication protocols or control drivers require ESD protection. Littelfuse offers a broad range of ESD diodes and polymer components tailored to different protocols, optimizing signal integrity while providing robust protection. Tables 1 and 2 recommend ESD diodes for various interfaces, with schematics showing configurations. For RF circuits, the recommended ESD diode has the lowest capacitance and leakage current, minimizing signal distortion. Example circuits illustrate TVS diode implementation for CAN and I/O interfaces.

Protecting the Automotive Ethernet physical layer, the backbone of zonal architecture

Automotive Ethernet is now the main communication interface in zonal control architectures due to its high data transmission rates, reaching up to 10 Gb/s—far exceeding other automotive protocols. Current rates are typically 100 Mb/s and 1 Gb/s. Ethernet’s lightweight, two-wire twisted pair, robust error-checking, and scalability make it ideal for the harsh automotive environment and future requirements.

The push for Ethernet in zonal architecture comes from the OPEN Alliance SIG, a non-profit group of automotive and tech providers promoting Ethernet as the standard for automotive networking. The top table in Figure 3 lists various “flavors” defined by the alliance, while the lower table compares automotive Ethernet with CAN and LIN protocols.

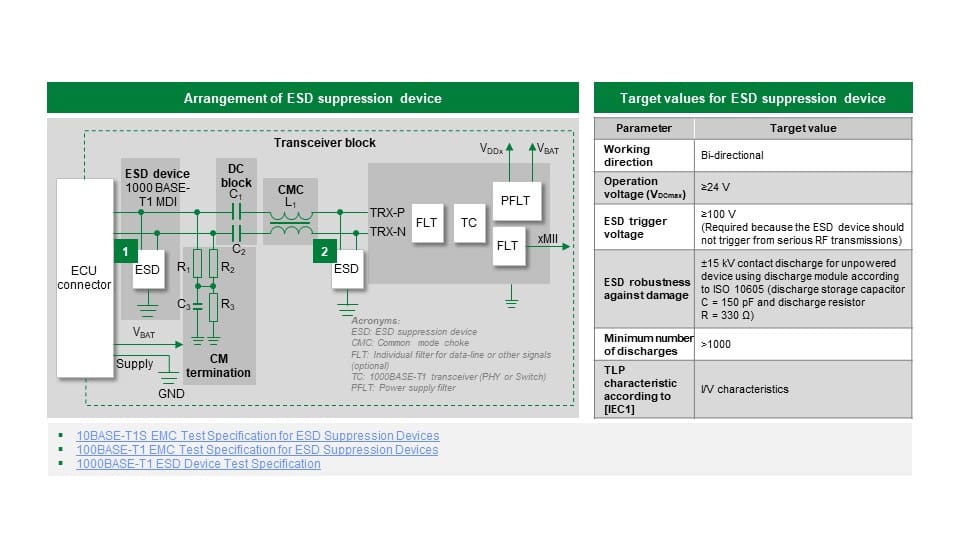

The OPEN Alliance has defined specific requirements for protecting automotive Ethernet circuitry from ESD. Figure 4 shows an Ethernet transceiver circuit with the ESD protection device’s recommended location called “1”. The adjacent table lists the OPEN Alliance’s requirements for an ESD suppression device. (The ESD protection “2” has no relation to the OPEN Alliance SIG.)

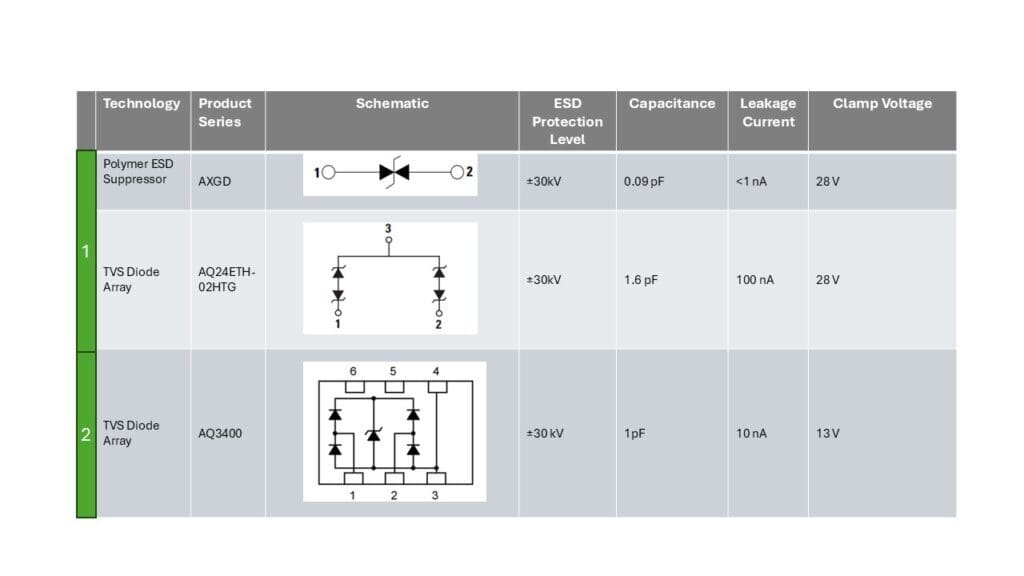

Littelfuse has developed numerous ESD suppression components for Ethernet protection, including one that specifically complies with the OPEN Alliance requirements. In addition to meeting the requirements of the OPEN Alliance for an ESD suppression device, the Littelfuse solution has low capacitance to minimize distortion of the Ethernet signals and low leakage to minimize energy consumption. Table 4 contains details on three options for Ethernet protection. The Polymer ESD suppressor has the advantage of the lowest capacitance and the lowest leakage current. The two TVS diode arrays protect two data lines in one package. All three components exceed the recommended ESD protection level called out by the OPEN Alliance SIG. They are all AEC-Q qualified; the Polymer ESD Suppressor to AEC-Q200 and the ESD Diodes to AEC-Q101. The AQ24ETH-02HTG is also certified to the OPEN Alliance specification.

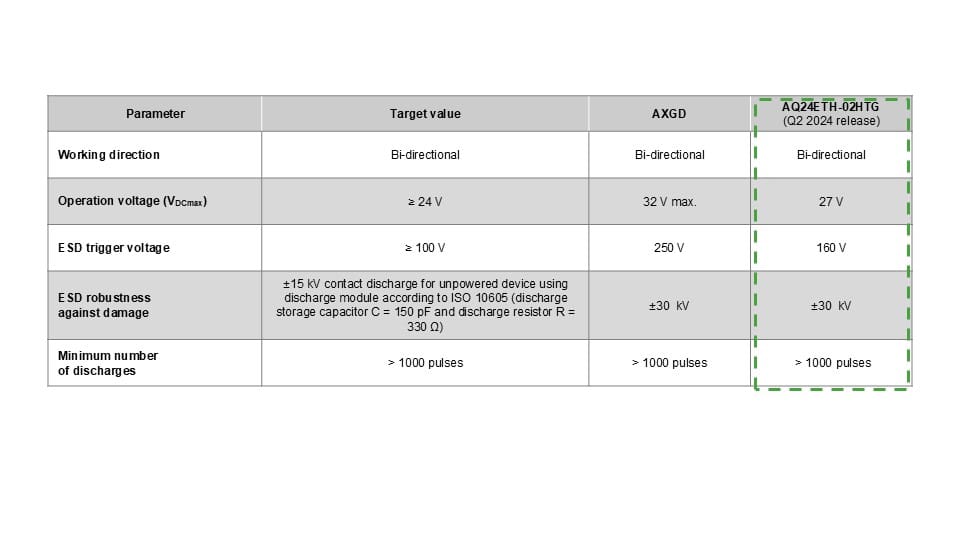

Table 5 compares the Polymer ESD Suppressor and one of the Diode Arrays with the OPEN Alliance requirements. Both exceed the OPEN Alliance’s ESD robustness against damage level. The OPEN Alliance has approved the AQ24ETH-02HTG TVS Diode Array to protect 100Base-T1 and 1000Base-T1 transceivers from ESD strikes.

Select optimum components for reliable and robust Zonal Control Units

The zonal control unit’s circuitry needs to withstand the electrical hazards inherent in the severe automotive environment. Designers can use the component recommendations for protecting the ZCU and all its interfaces to optimize their design process. By identifying protection components early, as well as consulting with a component manufacturer’s application engineers, designs can save development time and compliance costs. The application engineers can help with the following:

- Cost-effective components selection

- Compliance to the applicable safety standards

- Pre-compliance testing to avoid compliance failure and save on delays and costs for multiple compliance test cycles.

All the Littelfuse components presented are AEC-Q101 and AEC-Q200 qualified. Using these recommended components will ensure reliable and robust ZCUs with ESD-resistant interfaces.

Download the Automotive Electronics Applications Guide to learn more about evaluating these protection recommendations, courtesy of Littelfuse.