In times of great change, Marposs is taking up the challenge to remain a strong partner for the automotive market in the e-mobility era. The unprecedented global growth of electric motor technology, especially within the automotive sector, brings a whole new set of component reliability expectations to manufacturers and end users. This new trend has implications on the quality control and the process control requests of the production chain.

To meet the high-quality requirements for an e-motor, both in mobile and stationary use, measurement and testing technology must be applied systematically in the production process: first to meet the demand for safety and performance, and second to shift the production towards higher quality.

Motor testing is designed to check the integrity of an electric motor through the use of equipment that identifies potential issues within the motor. The main objective of motor testing is to reveal latent problems and prevent unnecessary failure by evaluating static parameters like insulation, wire damage and electrical current leakage, as well as more dynamic parameters.

The insulating system of electrical machines is a critical reliability feature since an insulation failure may result in a system breakdown. The standard electrical tests, required by regulations, are not sufficient to identify all types of failure, because many defects produce just partial discharges and these can only be identified using the partial discharge test method.

e.d.c.: Partial Discharge Measurement

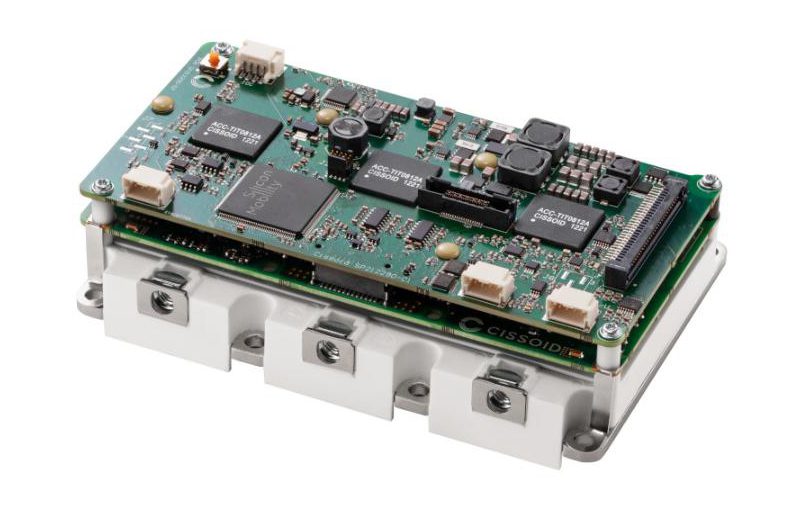

Established in 1964, e.d.c. is specialized in the design and production of testing systems for all kinds of electric motors and their components (stators and rotors), both in the laboratory and production environments. With the acquisition of e.d.c. srl, the first European company to integrate partial discharge into production environments since 1998, Marposs is able to offer a complete range of solutions dedicated to electrical and functional testing of any type of electric motor, including in-line and off-line applications for production and analysis activities in the laboratory. On the other hand, the entry in the Marposs Group will bring to e.d.c. enormous possibilities of development in the world market, thanks to the widespread presence of Marposs sales and service structure in 34 countries.

The Marposs e.d.c. partial discharge measurement system is based on capacitor coupling technology. As compared to antenna-type solutions normally applied in this market, the capacitor coupling technique is more sophisticated and less sensitive to external noise and, therefore, more suitable for applications in the production area. Since it does not use any external sensor, the coupling capacitor approach requires equipment able to detect the partial discharge just by connecting the terminals of the product under test with the same cables used to perform all other tests (winding resistance – AC High Pot tests – Surge Tests, …).

The effectiveness of Marposs e.d.c. technology in measuring partial discharge has been validated by some of the most experienced automotive and industrial companies, who selected Marposs e.d.c. as their supplier for electrical testing of e-motors using partial discharge measurement after more than a year of test comparisons against well-known German and American competitors.

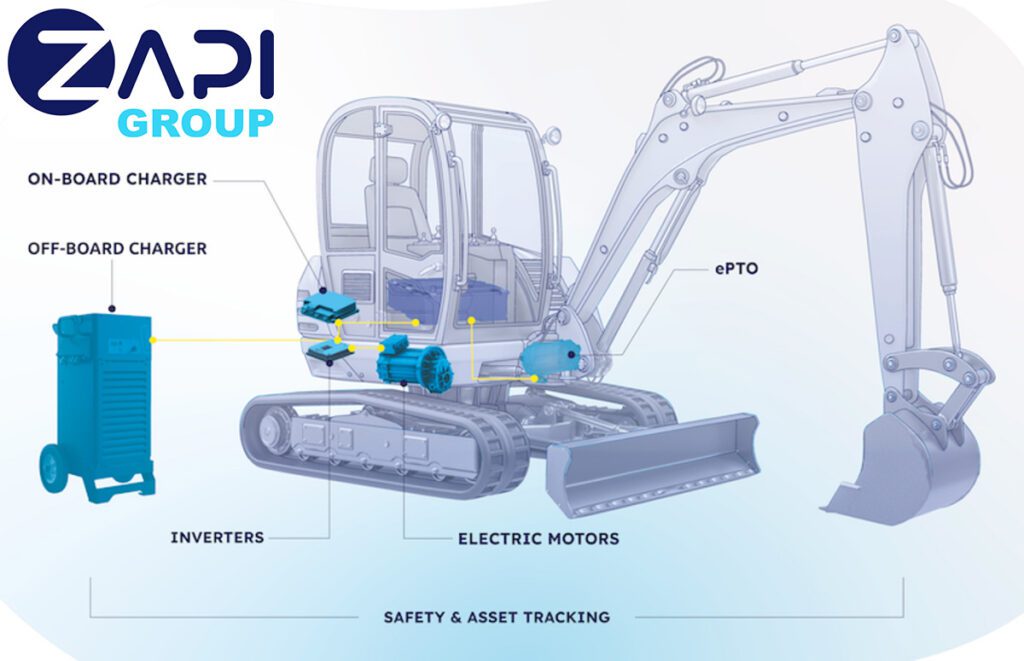

E-motors powered by an inverter

The e-motor insulation quality assessment is an important issue, particularly for e-motors powered by an inverter since their insulation is exposed to increased thermal/electrical stresses.

The most modern inverters have ever-higher switching frequencies, and this accentuates the reflection phenomena due to the impedance mismatch between the motor and the “cable / inverter” system. Large overvoltages can be observed at each voltage commutation, which could trigger partial discharge (PD), especially in phaseto-phase insulation which is subject to maximum voltage overshoot.

The PD Measuring method according to IEC 61934

The measurement and analysis of PD activity under pulsed voltages is, thus, an important task for preventing motor insulation failures. The IEC 61934 standard regulates the electrical measurement of partial discharge under short rise time and repetitive voltage impulses generated from electronic power devices, to verify the insulation quality of winding materials. The e.d.c. partial discharge measurement method, compliant to this standard, allows the determination of four characteristic voltage values as PDIV (Partial Discharge Inception Voltage), RPDIV (Repetitive Partial Discharge Inception Voltage), PDEV (Partial Discharge Extinguish Voltage) and RPDEV (Repetitive Partial Discharge Extinguish Voltage) through which the insulation of the winding is clearly qualified and can be provided with production tolerances.

The range of Marposs e.d.c. products also includes solutions dedicated to functional and end-of-line testing of any type of electric motor, for in-line and off-line applications or for laboratory analysis and characterization:

- Stator Tester for production lines (wound or hairpin) that includes partial discharge measurement,

- Rotor Tester for all kinds of rotors (with permanent magnets, squirrel cage, wound),

- Automatic EoL Motor Tester (with Load/No-Load tests) for production,

- Dynamometer for motor Load Test & Life Simulation Cycles for laboratory,

- Advanced Windings and Insulation Quality Analysers for laboratory.

Quality control of stators means checking various electrical characteristics along the entire production chain (wound or hairpin). In particular, the insulation tests with partial discharge measurementcarried out in different stages of the process represent a key operation in assessing the quality and reliability of the component.

Functional control of the rotors

The functional control of the rotors depends on the type of electric motor adopted and,therefore, on the rotor configuration. For squirrel cage rotors the quality control is carried out either manually or with fully automatic testing stations (for in-line integration), whose purpose is to identify defects inside the die-cast bars of the cage, such as interruptions in the material, porosities or defects in the connection to the end ring, geometric and shape errors.

In the case of permanent magnet rotors,manual benches or automatic stations are used to perform Back-EMF tests with FFT analysis.

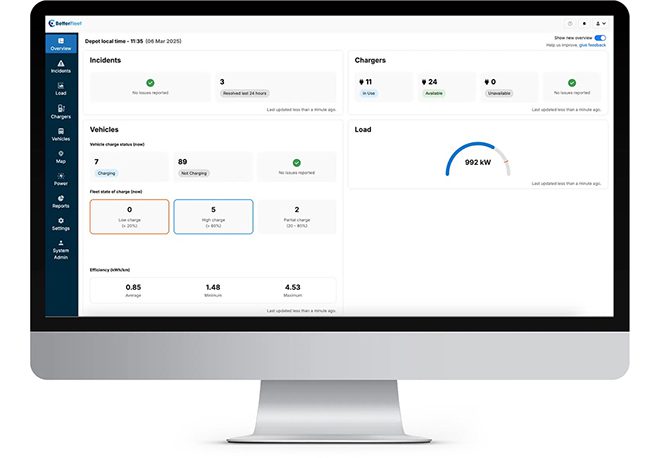

The end-of-line (EoL) functional test represents the key operation for quality control of the fully assembled electric motor and is responsible for the overall functionality of the product at the end of the manufacturing process.

The methods for carrying out the functional check may differ depending on the intended use for the testing station, for analysis activities in the laboratory during the product development and process set-up phase, or for the 100% quality control at the end of the assembly line.

During production, Marposs e.d.c. provides complete quality control of the electric motor including insulation tests to verify that the assembly operations have not compromised the perfect state of insulation, as well as a series of functional tests to evaluate dynamic parameters such as Vibration (NVH test), Dynamic or Passive BEMF with FFT analysis, Friction & Iron Losses, Zero Resolver Position and more.

In conclusion, for e-mobility to continue to grow at a rapid pace, the OEM as well as the end-user must be confident in the reliability of the vehicle functionality. As such, partial discharge measurement testing will play a crucial role as a standard testing process for electric motor manufacturers.