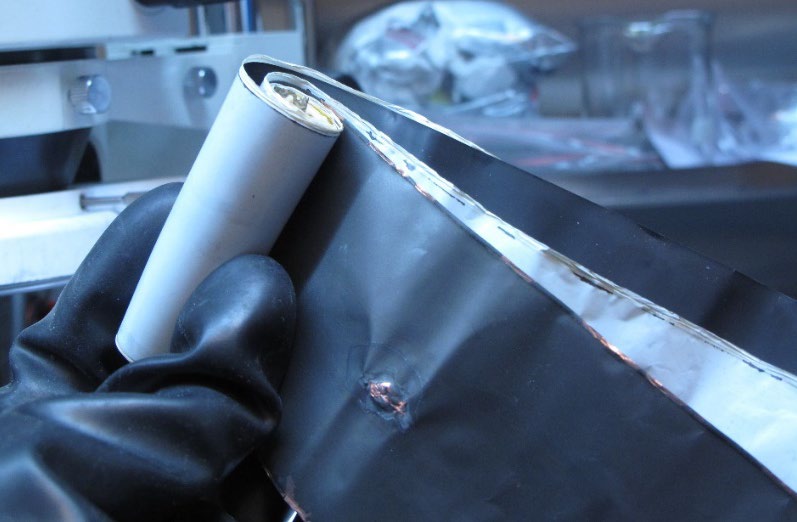

Nanostructure specialist Xtalic has created new nanostructured metal alloys and coatings for EV applications, including:

• Extending the life of charging connectors

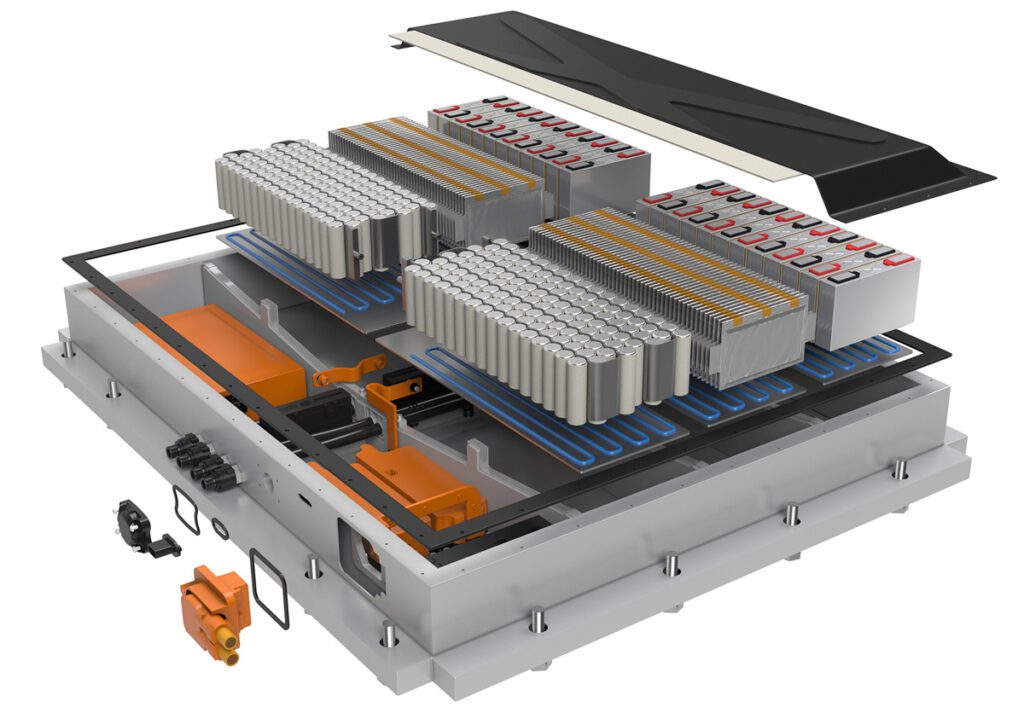

• Producing stable components for high-temperature environments

• Lightweighting

• Improving corrosion resistance

Equipped with Xtalic’s nanostructured allows, XTRONIC and LUNA, charging connectors achieve more than 10,000 charge cycles in real-world conditions, according to the company.

LUNA allows for extended operation at temperatures exceeding 200° C. XTALIUM offers improvement to temperature stability compared to traditional nickel and aluminum materials, and increases durability and corrosion resistance of lower-cost, lighter-weight materials, such as magnesium.

“EV suppliers are designing next-generation components that require the hardness, strength, corrosion resistance, and durability that traditional materials cannot provide,” said Tom Clay, Xtalic CEO. “Utilizing our proprietary Dynamic Nanostructure Control and patented Rapid Alloy Design toolkits, we are creating breakthrough alloys and coatings that meet the specific challenges of each application – and deliver a solution at the desired level of performance, economy, and environmental responsibility.”

Source: Xtalic