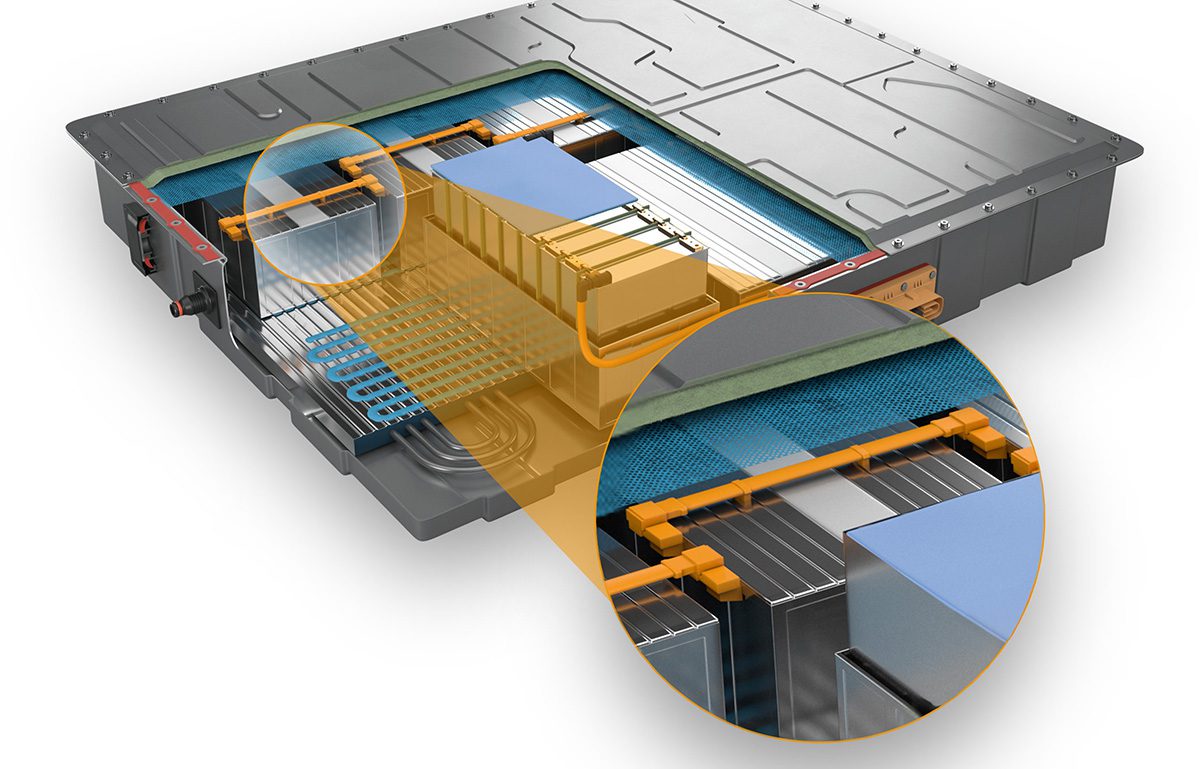

Wacker has announced a new extrudable silicone rubber designed to insulate busbars in high-voltage traction batteries for electric vehicles. The new material, ELASTOSIL R 531/60, addresses increased electrical and thermal demands resulting from rising EV battery voltages, with nominal system voltages commonly ranging from 300 to 900 volts. The company says the material’s processability by extrusion makes it a cost-efficient solution for large-scale component insulation.

According to Wacker, ELASTOSIL R 531/60 provides flame resistance and robust protection against leakage currents and energy losses. The insulation reportedly remains effective at continuous operating temperatures up to 205 °C. In the event of a fire, the cured silicone rubber forms a ceramic shell around the busbar, creating an electrically insulating layer that maintains protection and prevents short circuits at temperatures from 800 to 1,000 °C.

The silicone rubber features a hardness of 60 Shore A and can be extruded directly onto busbars, streamlining the sheathing process. Wacker says the material’s flexibility and tear strength enable insulated busbars to be bent and fitted into compact battery architectures without cracking or damage, even after impact testing. Additionally, the material maintains flexibility at temperatures as low as minus 40 °C, which helps dampen vibrations and impacts from vehicle operation, offering mechanical protection for traction batteries.

Wacker is presenting the new material at the K 2025 International Trade Fair for Plastics and Rubber, which takes place in Düsseldorf, Germany, from October 8 to 15, 2025.

Source: Wacker