In the quest for lighter and better batteries, companies are trying to think outside the box. But what about making the box itself into a battery? Volvo is developing a prototype material that can store and discharge electrical energy, and is also strong and lightweight enough to be used for car parts. The material can be shaped to fit around the car’s frame in various locations, substantially saving on space.

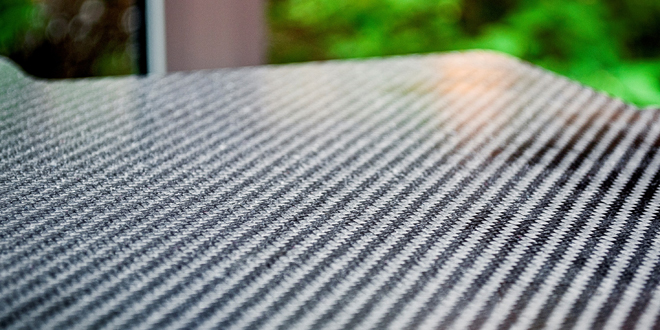

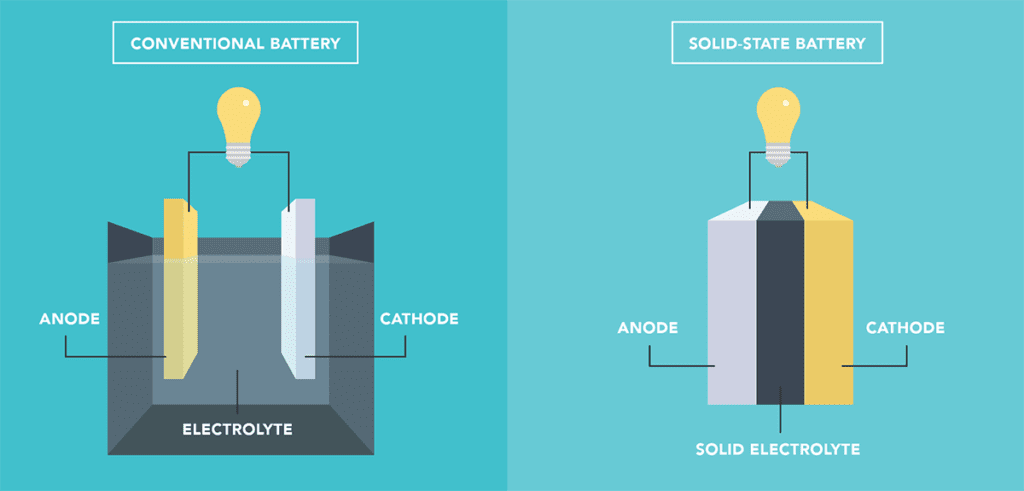

The new material, developed as part of an EU-funded research project, combines carbon fibers and a polymer resin, and structural supercapacitors. It is recharged and energized by the use of brake energy regeneration, or by plugging into the electrical grid. It then transfers the energy to the electric motor. The researchers have found that this material not only charges and stores faster than conventional batteries can, but that it is also strong and pliant.

Volvo has used the new material to build a trunk lid and a plenum cover, which it has installed in an S80 experimental car. The trunk lid is a functioning electrically powered storage component, and is lighter than a standard lid, saving on both volume and weight.

The new plenum can also replace both the rally bar, a structural piece that stabilizes the car in front, and the start-stop battery. This saves more than 50% in weight and is powerful enough to supply energy to the car’s 12 V system.

Volvo suggests that the complete substitution of an electric car’s existing components with the new material could cut overall weight by more than 15%.

Source: Volvo, Green Car Congress