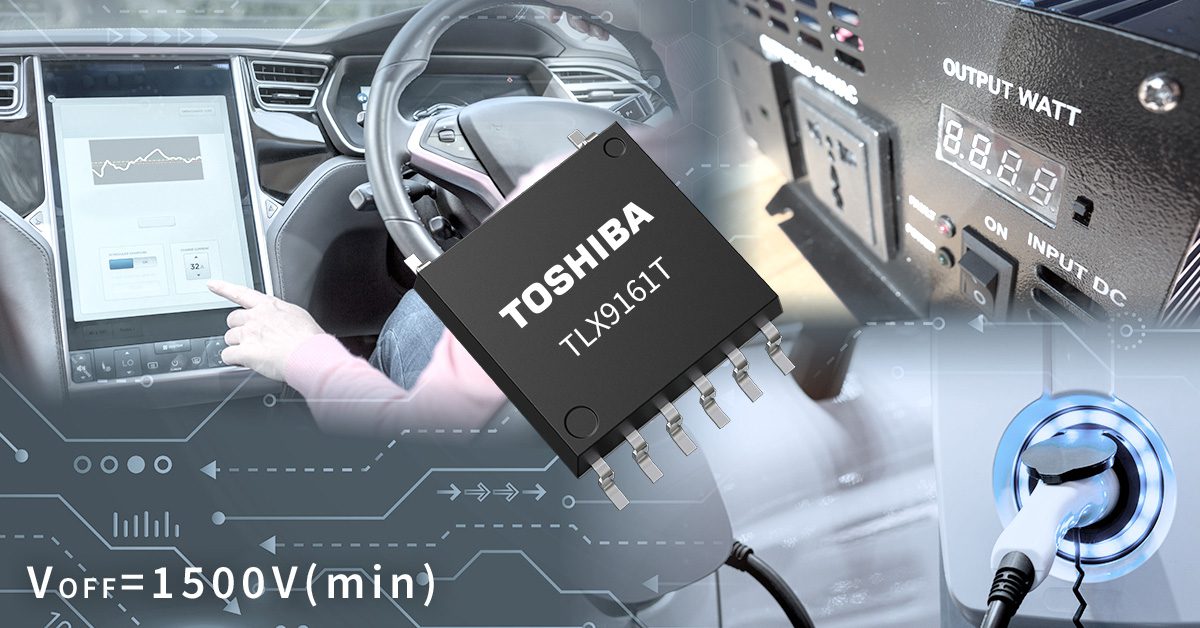

Toshiba Electronic Devices & Storage has introduced the TLX9161T automotive photorelay, designed to help EV manufacturers and battery system suppliers manage high-voltage battery packs. The TLX9161T, housed in a compact SO12L-T package, delivers a minimum output withstand voltage of 1500 V to meet requirements for high-voltage automotive batteries. Volume production has started.

The TLX9161T targets battery management systems in EVs, including functions such as battery voltage monitoring, mechanical relay sticking detection, and ground fault detection, where isolation and compactness are critical. Photorelays like the TLX9161T provide electrical isolation between control circuits and high-voltage switching components, supporting safer and more efficient battery system operation.

The TLX9161T achieves its high voltage performance in a footprint approximately 25 percent smaller than the previous TLX9160T (SO16L-T) model, with dimensions of 7.76 × 10.0 × 2.45 mm. This footprint reduction enables more compact and potentially cost-effective BMS designs. The pin pitch and layout match those of the SO16L-T package, allowing drop-in replacement on established circuit board designs.

Technically, the TLX9161T features a 1500 V minimum output withstand voltage, 5000 V root mean square (RMS) minimum isolation voltage, 0.6 mA avalanche current, and uses a resin with a Comparative Tracking Index (CTI) greater than 600—corresponding to Material Group I classification per IEC 60664-1. The pin configuration ensures a creepage distance greater than 5 mm on the detector side, supporting safe operation up to 1000 V in applicable environments. The device is AEC-Q101 qualified, addressing the needs of automotive-grade applications.

Source: Toshiba Electronic Devices and Storage Corporation

Topics: Toshiba Electronic Devices and Storage Corporation, Power Electronics