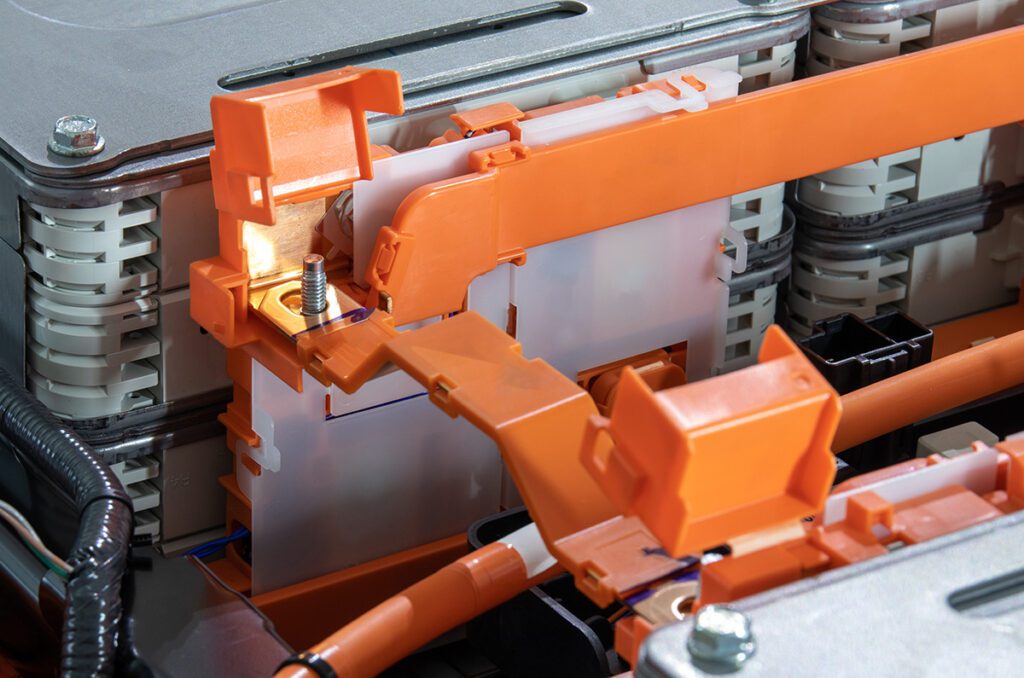

SABIC has introduced LNP THERMOCOMP WFC061I, a glass fiber-reinforced polybutylene terephthalate (PBT) compound designed for use in electric vehicle control unit (EVCU) covers. The specialty material offers non-brominated and non-chlorinated flame retardance, expanding options for engineers seeking to enhance fire safety in EV components without halogenated additives.

SABIC says LNP THERMOCOMP WFC061I enables significant weight reduction compared to traditional metal covers while enhancing design flexibility. The compound delivers structural protection for internal electronics against fire, smoke, impact and moisture. Other listed advantages include colorability, low warpage for improved yield and especially high optical transmission—20 percent at 3.0 mm thickness—supporting precision laser welding processes.

According to SABIC, this product as the world’s first flame-retardant PBT material suitable for laser welding. Laser welding compatibility enables manufacturers to join plastic components without the need for adhesives, fasteners or vibration—streamlining assembly and potentially accelerating throughput.

“The EVCU, which manages an EV’s electrical systems to ensure peak efficiency and a safe and enjoyable driving environment, relies on high-performance materials,” said Jenny Wang, SABIC’s Director of Formulation and Application. “Specialty resins must provide flame retardancy, strength, stability, light weight and precision manufacturing. Based on our broad understanding of automotive power engineering trends and requirements, SABIC developed its new LNP THERMOCOMP WFC061I compound to help protect the EVCU and optimize its reliability and functionality.”

Source: SABIC