Researchers at Pacific Northwest National Laboratory (PNNL) claim to have increased the conductivity of copper wire by about five percent. That may seem like a small amount, but it could make a big difference in motor efficiency. Higher conductivity would also mean that less copper would be needed for the same efficiency, which could reduce the weight and volume of various components that power EVs.

The laboratory teamed with GM to test the souped-up copper wire in motor components. As part of a cost-shared research project, the team says it validated the new copper composite’s increased conductivity and also found that it has higher ductility—the ability to stretch farther before it breaks. In other physical properties, it behaved just like regular copper, so it can be welded and subjected to other mechanical stresses with no degradation of performance. This means that no specialized manufacturing methods are necessary to assemble motors.

The technology can be applied to any industry that uses copper to conduct electricity, including power transmission, electronics, wireless chargers, electric motors, generators, under-sea cables, and batteries.

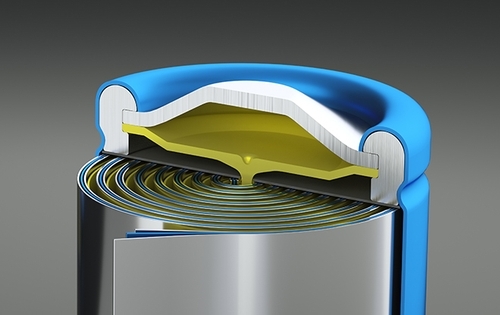

Using a new manufacturing platform developed at PNNL, researchers added graphene—a highly conductive, nano-thin sheet of carbon atoms—to copper and produced wire. The increased conductivity is made possible by a machine that combines and extrudes metal and composite materials, including copper.

PNNL says its Shear Assisted Processing and Extrusion (ShAPE) process can improve the performance of materials. Oppositional, or shear, force is applied by rotating a metal or composite as it is pushed through a die to create a new form. According to PNNL researchers, this approach creates internal heating by deforming the metal, which softens it and allows it to form into wires, tubes, and bars.

“ShAPE is the first process that has achieved improved conductivity in copper at the bulk scale, meaning it can produce materials in a size and format that industry currently uses, like wires and bars,” said Principal Investigator Glenn Grant. “The benefit of adding graphene to copper has been investigated before, but these efforts have primarily focused on thin films or layered structures that are extremely costly and time consuming to make. The ShAPE process is the first demonstration of considerable conductivity improvement in copper-graphene composites made by a truly scalable process.”

Adding graphene to copper has proved difficult because the additives do not blend uniformly, creating clumps and pore spaces within the structure. PNNL scientists say the ShAPE process eliminates pore spaces while also distributing the additives within the metal uniformly, which may be the reason for improved electrical conductivity.

“ShAPE’s uniform dispersion of the graphene is the reason only really tiny amounts of additive are needed—about 6 parts per million of graphene flakes—to get a substantial improvement of 5 percent in conductivity,” said PNNL material scientist Keerti Kappagantula. “Other methods require large quantities of graphene, which is very expensive to make, and still have not approached the high conductivity we’ve demonstrated at a bulk scale.”

“To further lightweight motors, advances in materials is the new paradigm,” said Darrell Herling of PNNL’s Energy Processes and Materials Division. “Higher conductivity copper could be a disruptive approach to lightweighting and/or increasing efficiency for any electric motor or wireless vehicle charging system.”

Source: PNNL