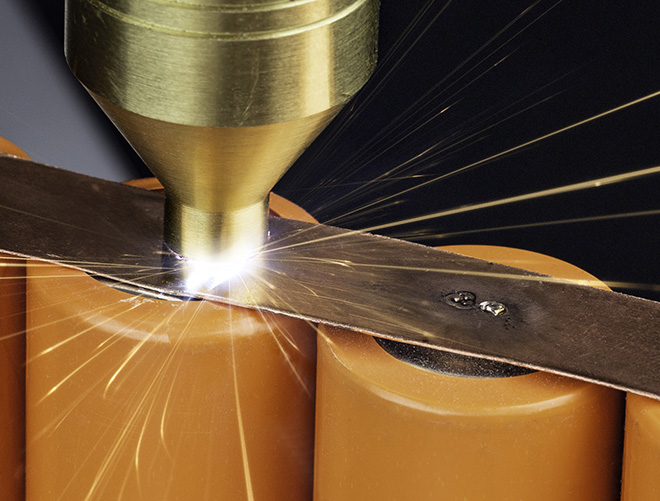

Sunstone Engineering, a manufacturer of high-tech micro-welding and engraving solutions, has developed a new battery welding system that’s capable of welding copper and nickel tabs to power cells.

Sunstone’s Omega PA250i includes new welding technology that clears a path for battery manufacturers to use pure copper or nickel tabs in the production of power cells. The high conductivity of copper tabs can improve the performance of a power cell. However, until now, battery manufacturers have been limited to mixed metal tabs, which are easier to produce but offer less efficient conductivity.

The Omega PA250i can be configured in three different ways to match the needs of the manufacturer. For R&D, the stylus configuration provides the lab with 5X optics and pulse arc welding technology. For mid-size production facilities, a weld held configuration may be more suitable. For large-scale production facilities, the Omega PA250i, with its PLC capabilities, connects to a CNC-mounted weld head.

As are many of Sunstone’s micro-welders, the Omega PA250i is controlled by a mounted touchscreen interface. The operator can digitally control all aspects of the weld, from power to waveform to agitation. When the operator enters the type and thickness of the metals to be welded, the Omega will automatically set the weld parameters for an optimum weld for that combination of metal and thickness.

The Omega’s digital control also offers the ability to save welds, then load and apply those settings to similar jobs in the future. Weld settings can also be cloned from one unit to another, which saves time in setting up production processes.

“The Omega opens up new possibilities for battery manufacturers,” says Sunstone Engineering President Jonathan Young. “They can take advantage of the conductivity benefits of copper or nickel tabs without affecting production levels. With an Omega, our customers can develop a significantly more efficient power cell and produce it just as easily as any other.”

“The specificity of the Omega is the key to why it is able to consecutively produce optimum welds,” Young continues. “Sunstone has advanced weld control far beyond what our clients expected even a year ago. A successful weld, for any type of metal or combination of metals, is the result of being able to adjust and tinker with every known contributing factor. And now, with the Omega, the technology is automatically adjusting the welder based on the materials involved to create an optimum welding result.”

Source: Sunstone Engineering