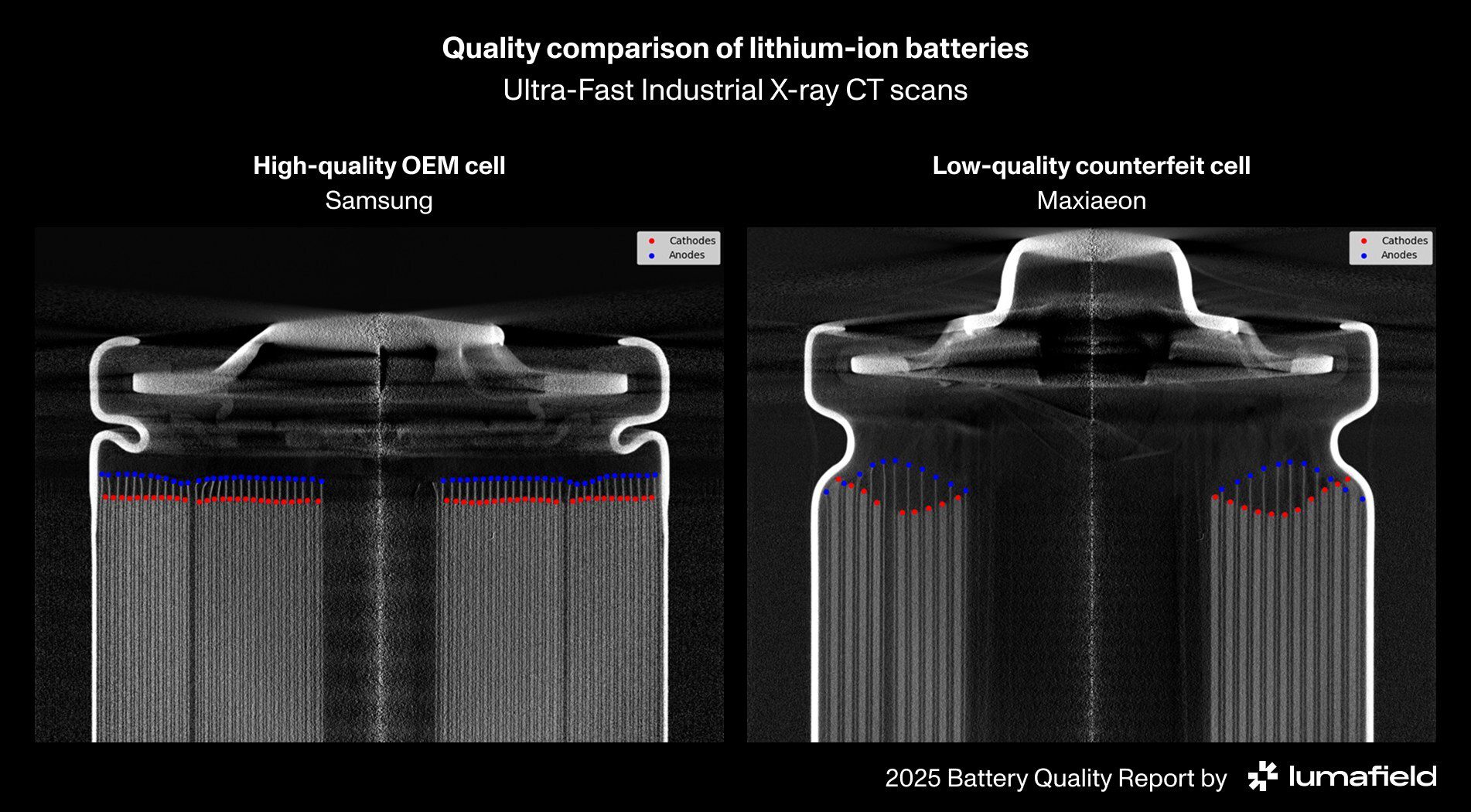

Industrial X-ray CT technology provider Lumafield has released the results of a study evaluating the safety and quality of lithium-ion batteries. The study found that 1 in 13 low-cost or counterfeit batteries could have a dangerous defect known as negative anode overhang.

The study also found that key indicators of quality in low-end batteries are seven times worse compared to those of name-brand manufacturers, introducing further risk.

OEM batteries exhibit high quality control. They are designed to have tightly aligned layer edges and even anode-cathode overhang. Cheap, off-brand batteries may have highly variable anode-cathode overhang and a dangerous defect called negative anode overhang.

The research evaluated more than a hundred 18650 lithium-ion battery cells from each of ten brands, using industrial X-ray CT scans from Lumafield’s CT scanner and Battery Analysis Module. The results indicated a wide gap in quality between brand-name batteries and cheap cells that are widely available through online marketplaces.

Of the 1,054 battery cells scanned, 33 had negative anode overhang, a manufacturing defect that accelerates aging and increases the risk of internal short-circuiting and battery fires. All 33 of the defective cells came from low-cost or counterfeit brands.

Don’t miss next week’s webinar presented by Lumaflied:

How industrial CT scanning provides EV battery reliability insights

One low-cost brand had a 15% rate of negative anode overhang defects, a high risk to consumers who may be tempted to buy inexpensive batteries online.

“The quality of these battery cells varies significantly between brand-name OEM cells, re-wrap cells that have had their plastic wrapper removed and replaced (often with inflated specs) and low-cost or counterfeit cells that are increasingly flooding online marketplaces like Temu and Amazon,” Lumafield stated.

Low-cost or counterfeit 18650 cells had 50% worse edge alignment, referring to the winding of the internal layers of the cylindrical battery, compared to cells manufactured by OEMs.

Battery defects like negative anode overhang and alignment misregistration significantly increase the risk of failure, impeding performance of the devices they power, or even causing catastrophic fires in certain cases.

The risks in individual cells are compounded by the fact that many products include multiple 18650 cells—from 5 in a typical cordless drill to 39 in an e-bike battery pack that Lumafield CT scanned for the study.

“Non-OEM batteries are a minefield,” said Eduardo Torrealba, co-founder and CEO of Lumafield. “We’re seeing dangerous defects at a scale that should alarm every manufacturing leader. If you’re not policing your supply chain, you’re gambling with your brand and your customers’ safety. With trade barriers shifting weekly, risk compounds. Rapid industrial CT isn’t optional; it’s the best way to enforce safety and stop bad parts before they reach people.”

Source: Lumafield