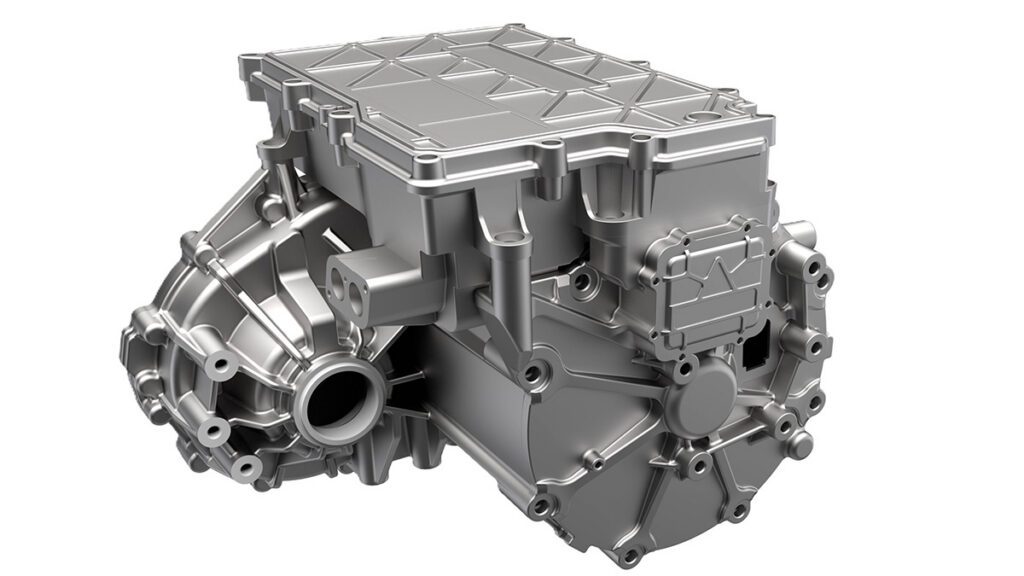

US battery technology developer Sion Power has taken a step toward commercializing its Licerion battery technology by installing a new large-format battery cell production line, which it developed in partnership with Germany’s Muhlbauer.

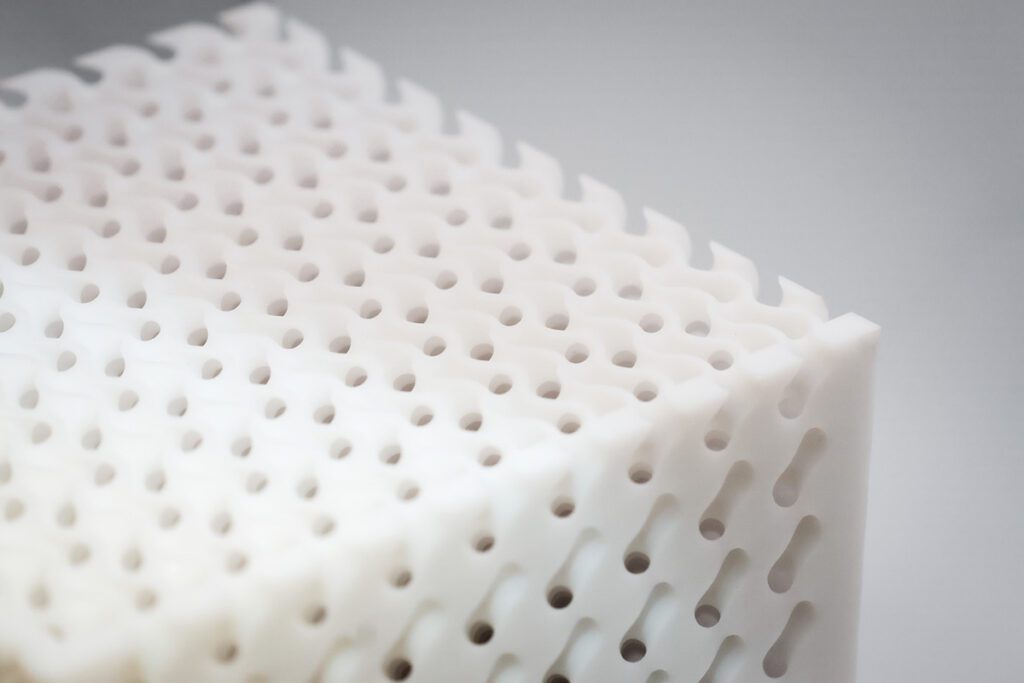

The new fully automated manufacturing line will be capable of producing 75 MWh of 56 Ah lithium metal cells annually. It will produce large-format battery cells exceeding 50 amp-hours, advancing Licerion technology to meet automotive standards.

Sion Power previously used an automated assembly line to produce a variety of cell formats, including lab-scale and six-amp-hour cells, while using a semi-automated line for larger-format cells. Adding the new line increases throughput and improves stacking, sealing, and anode preparation precision—enhancing the company’s production efficiency and quality control for larger-format cells.

The new line supports Sion Power’s continued innovation and testing across various cathode chemistries, provides high-capacity cells for strategic partners to conduct their own testing and supplies potential customers with large-format cells to evaluate Licerion technology in various applications.

Sion Power expects Licerion to reduce the cost of a 200 kWh pack by 35% through a 15% cut in cell material costs and a 20% reduction in cell count. It also enables charge times comparable to a gas station’s eight-minute average refuel time.

At over 400 Wh/kg, Licerion batteries offer twice the energy of traditional lithium-ion batteries in the same size and weight, according to the company.

“The ability to scale performance from small prototype cells to large-format cells is often where battery technologies face the greatest challenge,” said Tracy Kelly, President at Sion Power. “Our new manufacturing line bridges that gap, demonstrating the capability of our lithium-metal battery technology in formats applicable to real-world applications.”

“Our Licerion technology unlocks the potential of lithium metal to leapfrog current graphite and silicon anode solutions,” said Pam Fletcher, Sion Power CEO. “With this new cell production capability, we will provide large-format test cells with both LFP and NMC cathodes for our US and global customers, including our strategic partners like LGES as well as global battery cell manufacturers and automotive OEMs, at a much higher rate while maintaining the quality standards required for next-generation battery development. This is a significant step in developing lithium metal chemistry and helps ensure we will be volume production-ready in 2028.”

Source: Sion Power