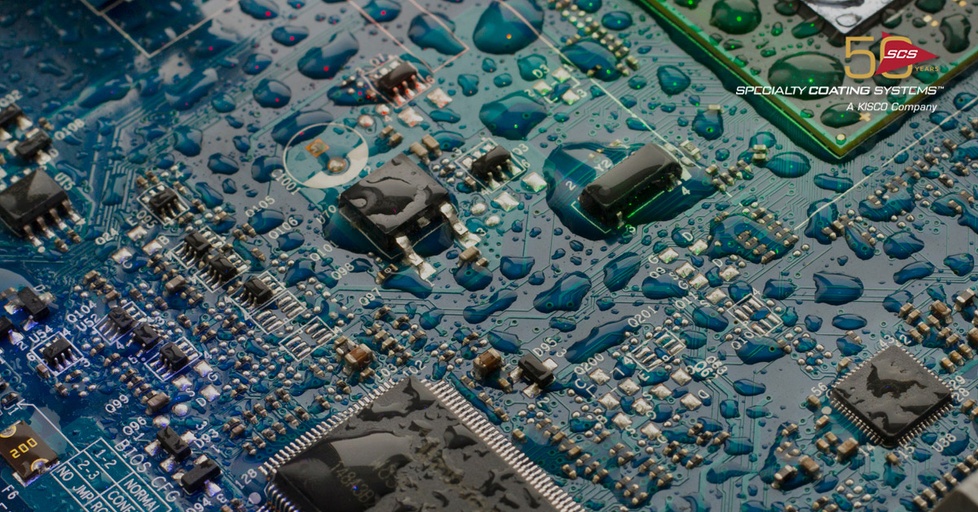

Introducing the right materials early in the design phase of an EV system helps to optimize cost and design. One common challenge is protecting vehicle electronics, PCBs, sensors and components from moisture, electrical shorts, corrosion and more. OEMs and Tier 1 product designers have turned to conformal coatings to optimize their systems to handle these real-world challenges.

Join this webinar session at our Spring Virtual Conference on EV Engineering, presented by Specialty Coating Systems, where we will explore various conformal coatings to help you select the right material for your product design and early design testing.

Other sessions at our Spring Virtual Conference include:

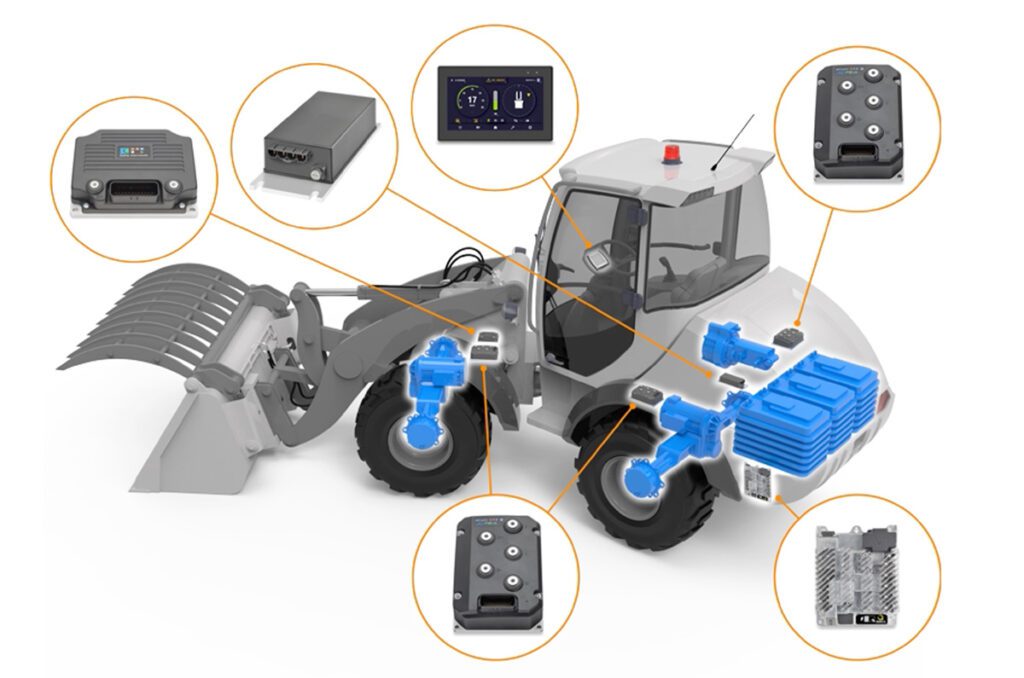

Flexible R&D Sintering System For Cu Materials: PINK SIN 20

The SIN 20 was developed to support R&D and evaluate and set up sintering processes for power electronics manufacturing. The universal Softtool of PINK allows processing of different designs without investments and developments of new top sinter tools. This results in fast development cycles and highest flexibility in the sample manufacturing process. It also provides a tooling interface for fast turnover of different tooling. Different sizes of Softtools are possible as well as the installation of a hard stamp device.

In addition, the complete process is done inside a hermetically sealed chamber, allowing perfect control of the O2 content during processing. Sintering on Cu surfaces or also the use of Cu-sinter pastes can easily be realized. The system provides a pressure and position control of the press during the process at pressures up to 30MPa.

The intuitive user interface supports the process engineer setting up and analyzing different process steps. Based on its size and flexibility the equipment is suited for R&D as well as small-scale manufacturing of a wide range of components.

Register here to learn more—it’s free!

See the full sessions list for the Spring Virtual Conference on EV Engineering here.

Broadcast live April 4 – 7, 2022, the conference content will span the EV engineering supply chain and ecosystem including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.