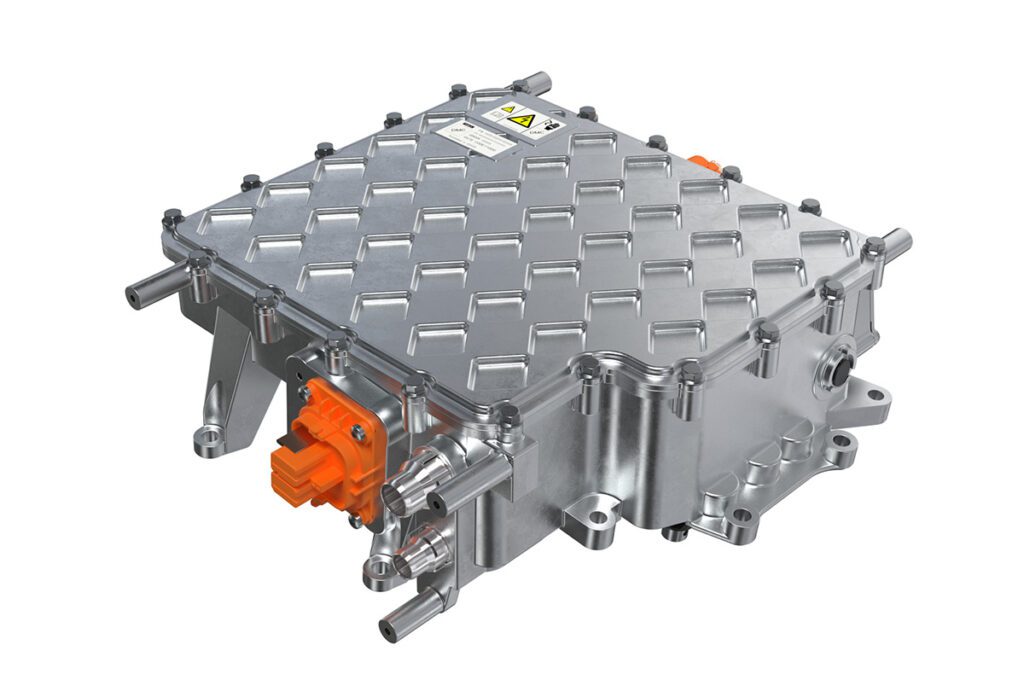

Michigan-based test system company SAKOR Technologies has delivered a new dynamometer test system to Carpenter Technology. The system will be used to test the effectiveness of new alloys in inverters and electric motor parts.

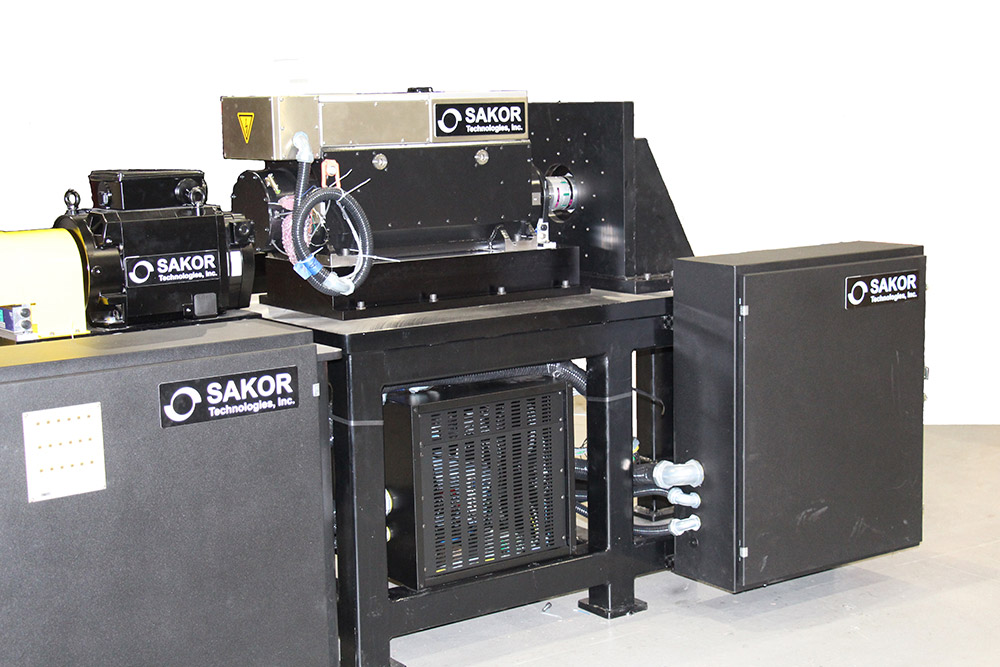

The system is composed of an AccuDyne 250 kW four-quadrant AC dynamometer, an AccuDyne 12 kW four-quadrant AC dynamometer, a 250 kW / 800 VDC battery simulator, two universal inverters, SAKOR’s DynoLAB test automation controller and a cooling system for air- and water-cooled motors and inverters.

“The AccuDyne four-quadrant dynamometers are capable of full bidirectional loading and motoring of the device under test,” says SAKOR. “They can also provide full rated torque at stall. Each dynamometer, as well as the battery simulator, provides regenerative power recapture. This makes the test system itself extremely power-efficient and greatly reduces operating costs.”

“The customer needed a machine that could test a very broad range of motor sizes and powers, and this new system allows them to test new motor technology with or without customer inverters, making it extremely versatile,” says SAKOR President Randal Beattie. “This single system will take the place of as many as four independent test stands.”

Source: SAKOR Technologies