In the holy quest for a better battery, engineering simulation software is a key tool, helping battery developers to shorten the time-consuming cycle of prototyping and manufacturing. Software developer ANSYS (NASDAQ: ANSS) has now incorporated battery models in the latest release of its Fluent software, thanks to the efforts of a team that also includes GM and the DOE’s National Renewable Energy Laboratory (NREL).

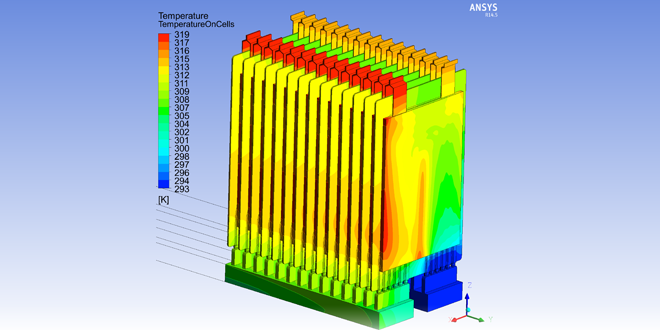

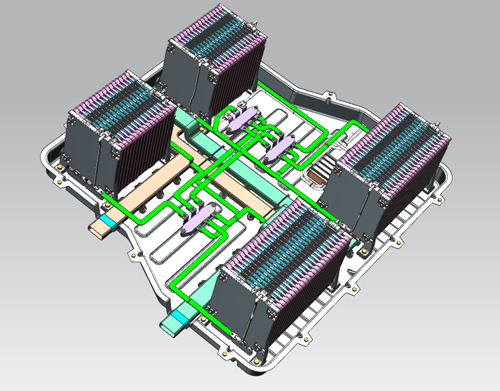

Over the last couple of years, the team worked on a DOE-funded project, Computer-Aided Engineering for Electric Drive Vehicle Batteries (CAEBAT), to combine new and existing battery models into simulation software. The team is modeling thermal management, electrochemistry, ion transport and fluid flow.

“The emphasis in the software integration has been to provide a flexible array of modeling choices that can support several categories of battery researchers, cell manufacturers, pack integrators and vehicle manufacturers that deliver fast and accurate results,” said GM’s Jan Aase. “With a concise plan for rapid deployment to the industry, the software solutions created through this project are already helping designers and engineers at GM to accelerate the pace of battery innovation and development for future electric-drive vehicles.”

The collaborators integrated several physical battery scales (electrodes, cell, pack and full vehicle) and physical phenomena (electrochemical, thermal, fluid and structural), and blended detailed 3-D field simulation technologies with systems-level simulation.

“The CAEBAT project has been a great opportunity for ANSYS,” said Sandeep Sovani, the company’s Director of Global Automotive Industry. “We are partnering with other recognized leaders in EV battery technology to develop and deliver powerful modeling tools that can be used by all battery manufacturers to accelerate production of safe, reliable, high-performance and long-lasting EV batteries.”

The team will continue to refine automation techniques and validate the models with experiments. Future features will include cycle-life and abuse (such as overheating) models, as well as NREL’s multi-particle model, with the ability to model a mixture of active materials with different particle sizes.

Source: ANSYS