Sandeep Sovani on the evolution of computer-based engineering simulations.

Before actually creating any physical prototypes, engineers build a three-dimensional virtual model of a component, and can use computer simulations to test how the design will perform in the real world. Computer-based engineering simulation early in the development process allows them to refine and validate designs at a stage where the cost of making changes is minimal. Simulations are highly efficient virtual tools, and ANSYS is a clear leader in the space. As Fortune pointed out, ANSYS products are used around the world by 96 of the top 100 industrial companies on the Fortune Global 500 list.

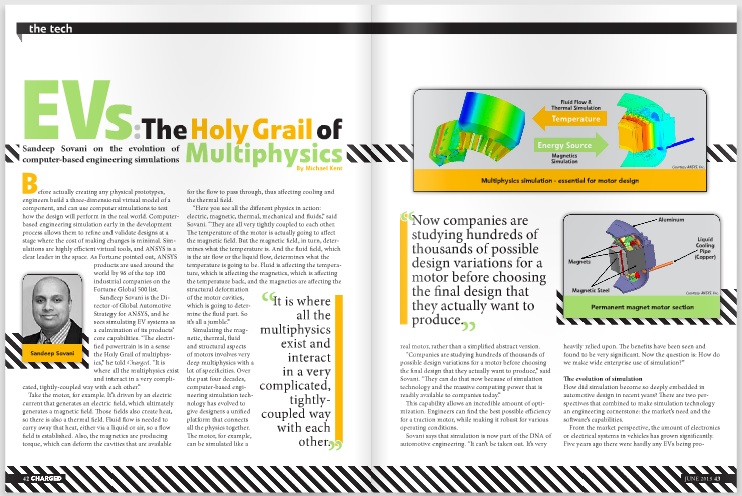

Take the motor, for example. It’s driven by an electric current that generates an electric field, which ultimately generates a magnetic field. Those fields also create heat, so there is also a thermal field. Fluid flow is needed to carry away that heat, either via a liquid or air, so a flow field is established. Also, the magnetics are producing torque, which can deform the cavities that are available for the flow to pass through, thus affecting cooling and the thermal field.

“Here you see all the different physics in action: electric, magnetic, thermal, mechanical and fluids,” said Sovani. “They are all very tightly coupled to each other. The temperature of the motor is actually going to affect the magnetic field. But the magnetic field, in turn, determines what the temperature is. And the fluid field, which is the air flow or the liquid flow, determines what the temperature is going to be. Fluid is affecting the temperature, which is affecting the magnetics, which is affecting the temperature back, and the magnetics are affecting the structural deformation of the motor cavities, which is going to determine the fluid part. So it’s all a jumble.”

Simulating the magnetic, thermal, fluid and structural aspects of motors involves very deep multiphysics with a lot of specificities. Over the past four decades, computer-based engineering simulation technology has evolved to give designers a unified platform that connects all the physics together.

“Companies are studying hundreds of thousands of possible design variations for a motor before choosing the final design that they actually want to produce,” said Sovani. “They can do that now because of simulation technology and the massive computing power that is readily available to companies today.”

This capability allows an incredible amount of optimization. Engineers can find the best possible efficiency for a traction motor, while making it robust for various operating conditions.

Sovani says that simulation is now part of the DNA of automotive engineering. “It can’t be taken out. It’s very heavily relied upon. The benefits have been seen and found to be very significant. Now the question is: How do we make wide enterprise use of simulation?”

The evolution of simulation

How did simulation become so deeply embedded in automotive design in recent years? There are two perspectives that combined to make simulation technology an engineering cornerstone: the market’s need and the software’s capabilities.

From the market perspective, the amount of electronics or electrical systems in vehicles has grown significantly. Five years ago there were hardly any EVs being produced, and the amount of electronics content in a vehicle was much smaller than it is today. Over these years the need for multiphysics simulations has increased steadily, because new vehicles are now seeing increased electrical currents, magnetic fields and electromagnetic radiation, along with the accompanying thermal, structural and fluid flow considerations. Vehicles are much more tightly packed with electronics and different electrical attributes, and there is no end in sight, either from an electric powertrain or a consumer electronics perspective. In turn, multiphysics simulations have become more important.

From the software-capability perspective, ANSYS’s recent product development serves as a good example of the shift in technology focus. About 10 years ago, Sovani explains that ANSYS realized there was a need for multiphysics coming. “We started out as a structural company, but we did strategic acquisitions to add different physics into our portfolio. And while we were doing those acquisitions, we did strategic development investment in a platform that brings all these physics together in a seamless way. So you can take one motor model and do structural analysis, computational fluid dynamic analysis, electromagnetic analysis – all on the same model.”

The company’s vision is clearly seen now, and ANSYS’s “strategic investments” seem to be money well spent. As the development of electric drives increases, the need for multiphysics platforms will only grow.

To predict what’s next for simulations, Sovani suggests we look at how it has evolved, starting in the beginning of the 1970s. “I like to classify the four decades of simulation using four questions that companies were asking, like auto companies that encountered simulation and wanted to use it.”

The first was: What is simulation? “People were trying to deal with all these numbers coming out of those fledgling computers that were around in those days,” said Sovani.

In the second decade, the 1980s, the question was: Does it really work? “We now understand what simulation is, but does it really give answers that compare with experiments?”

Then, in the 1990s, they were asking: Does it work in my application? “We now know that simulation works in generic problems, such as simple square beams and shells, but does it work for my real-life problem like a traction motor or aerodynamics? And again, all of the answers were yes,” said Sovani.

And in the last decade, the 2000s, the question was: We know it works for my application, but how do we use it in production? “The last decade in the auto industry was spent creating processes and practices for systematic use of simulations in the product development process.”

And now, in this decade, it’s all about: How do I make massive use of simulation, or enterprise-wide use of simulation?

Coming trends in simulation technology include things like high-performance computing – using very large computers to significantly cut down the amount of time required to do a simulation or extensive design exploration, like studying thousands of motor variations.

Scaling the details

So, apart from the complicated interaction of multiphysics, there is a problem with doing multi-scale simulations in batteries.

“If you think about doing a high-fidelity simulation for an electrode pair, on the one millimeter dimension, you can’t do that simulation for every pair in the entire battery pack,” explained Sovani. “That would be a huge computation, it would require thousands of computers to run on. But we do require that deep simulation to characterize the behavior of the electrode and the electrochemistry. So, what is needed in a system simulation is the ability to do high-fidelity simulations for specific pockets. And then to abstract the results of those simulations and create what we call a reduced-order model. It is a simpler model that will run faster on the computer, but it will mimic the high-fidelity model. Then put that reduced-order model in a detailed model of the next higher level object in the system.”

In other words, create a reduced-order model for an electrode and put that in a cell. Then do a cell simulation, create a reduced-order model of that cell and then put that in a module level simulation. Then again for the module and put it in a pack simulation.

“That way we can maintain good accuracy throughout the system, and accurately simulate the pack as a whole system with all its electronic controls, as well as the behavior of the physical objects inside of the system.”

Ultimately, there is a lot of opportunity to improve fuel economy and the range of an EV just by optimizing the battery, traction motor and power electronics in conjunction with the whole vehicle system. Currently, automotive engineering is very components-based. The problem is that 20 optimized components don’t create an optimized system when put together. The system has to be independently optimized, and the components have to be optimized with respect to the system.

“It’s about changing culture. I would say the biggest challenge in simulations is not really about technology, it’s about culture of automotive product development. Today, the battery and the motor are developed separately. There is not as much effort as could be done to develop them as a system. Because things are done this way, there is a loss in efficiency which is so critical for EVs.”

ANSYS’s success has come from keeping a constant eye on what’s next, and taking the right steps as a company to lead the trends. Ten years ago, it started to invest in multiphysics platforms and now those simulations are a required, invaluable engineering step.

As an automotive strategist, a big part of Sovani’s job description is looking forward. “I envision a world 10 years from now where model-based system engineering is very prevalent. When we start creating a car at that time, we create a functional architecture of the car, and it’s all managed through one coherent piece of software. All the way from that point, to the point where the vehicle’s components are designed in detail and then integrated. I see the world in the next decade as a high-level system optimization world.”

Engineering notes: Model-based system engineering

Model-based system engineering is a new design technique that is now just beginning to be implemented in the automotive development culture.

It starts by constructing a virtual model – not a geometric model but a model of the system – taking in the requirements and laying out a rough architecture. It uses a functional design of various parts of the system with, essentially, block diagrams. Each block has certain inputs and functions that it has to do. One could be a motor, one could be a battery, one could be power electronics, etc. For each of those functional attributes there is a more detailed design. You take the battery box and expand it further into functional designs of different modules, different controllers, etc.

Then, the rough architecture goes into creating different physical models, like 3D CAD models of the different systems and FEA models for testing those systems. In a sense, it is a hierarchy of models that are increasingly more complex and detailed.

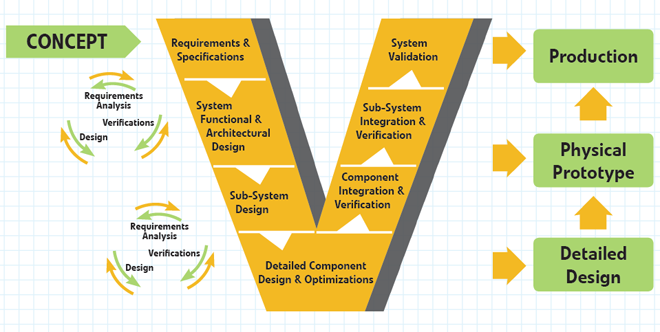

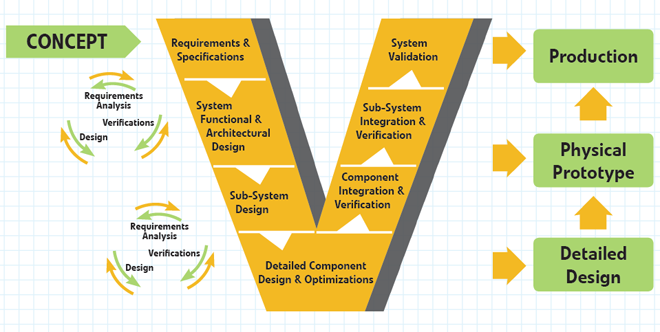

The V-model, or system-V, is a terminology used in this model-based product development approach. On the top left side of the V, the process begins with the rough concepts and requirements. As you go down the left side you make a more detailed design of the product. A functional architecture of the main system, then functional architecture of the sub-components and systems, and at the bottom of the V are the detailed CAD, FEA, and CFD models and multiphysics analysis. So essentially it goes from requirements to the detailed design at the bottom.

On the right side of the V is the opposite, where we go from the detailed models to subsequent higher levels of implementation and testing. Starting with testing of components and subsystems, and ultimately testing of the whole system as one. At all levels there is a comparison of the right side to the left side, verifying that the whole system and its performance matches the original requirements that were set on the left side of the V.

So, model-based system engineering is a way of doing computer models that can take a complete product down from the left side of the V and up the right side.

This article originally appeared in Charged Issue 8 – JUN 2013 ![]()

![]()