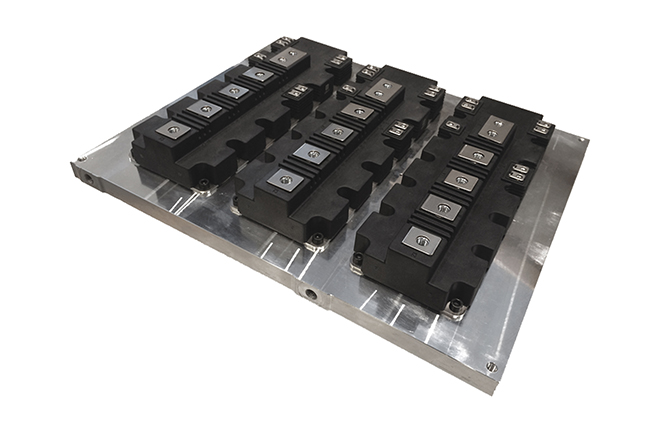

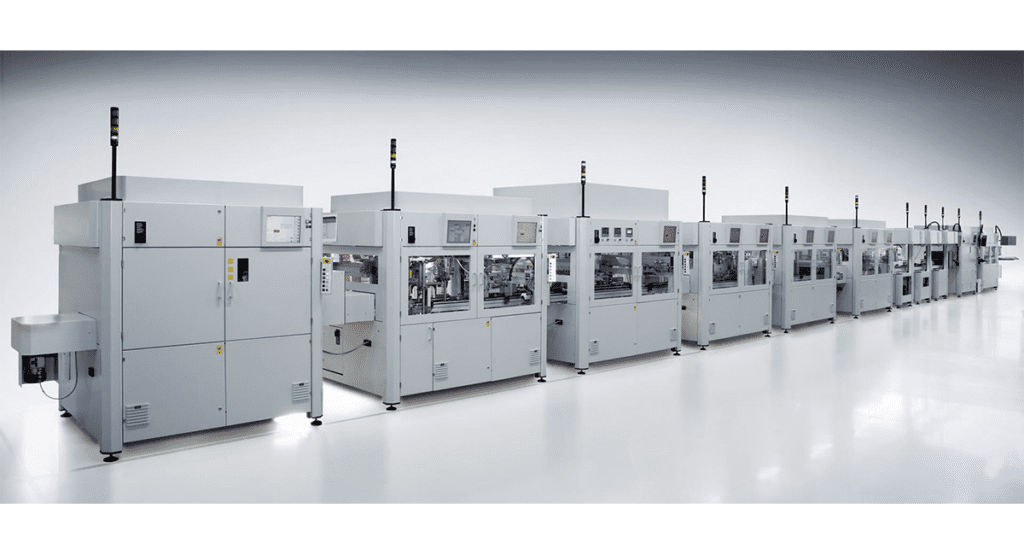

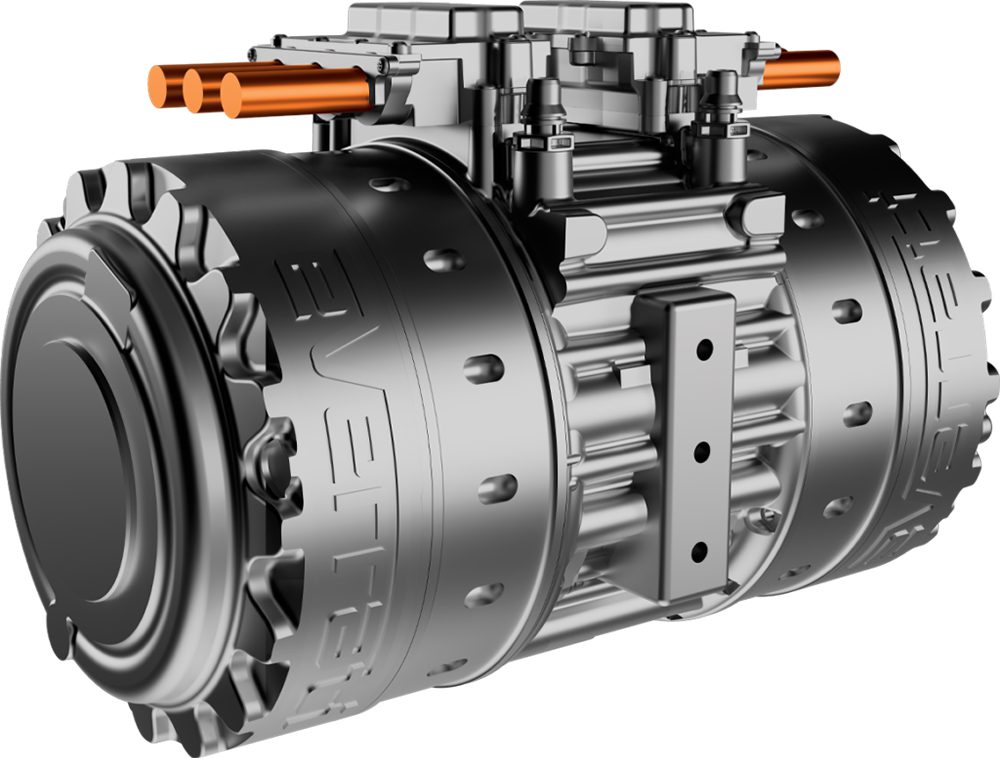

Electrical component manufacturer Mersen has developed a new cold plate product designed to provide high cooling capacity with minimal pressure drop. According to the company, its new IsoMAXX cold plates are designed to meet the high demands of modern power electronics, and have been specially developed for the latest SiC, GaN or IGBT power modules.

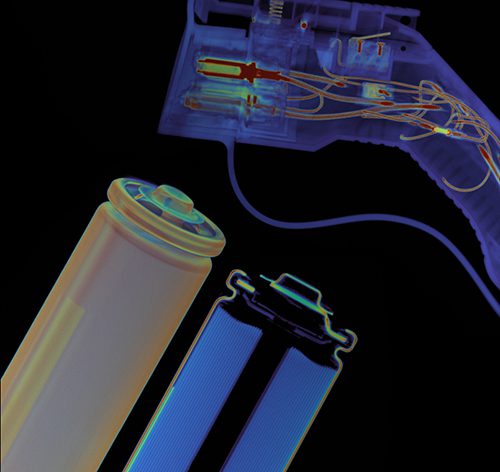

Modern EVs and renewable energy generators increasingly use wide-bandgap electronics, which are optimized for operation at high switching frequencies and temperatures. According to Mersen, conventional heat sinks cannot meet today’s high cooling requirements.

That’s why Mersen developed IsoMAXX, a vacuum-brazed cold plate with an average thermal resistance (Rth) of 6° C per kW and a pressure drop of ~600 mbar, substantially lower than that of the company’s previous models. IsoMAXX cold plates ensure an optimal temperature range for power electronics, in which all single chips and modules on the cold plate remain at the same temperature. No minimum clearance is required between modules, which allows versatile integration regardless of the number of modules needed for a particular application.

Source: Mersen