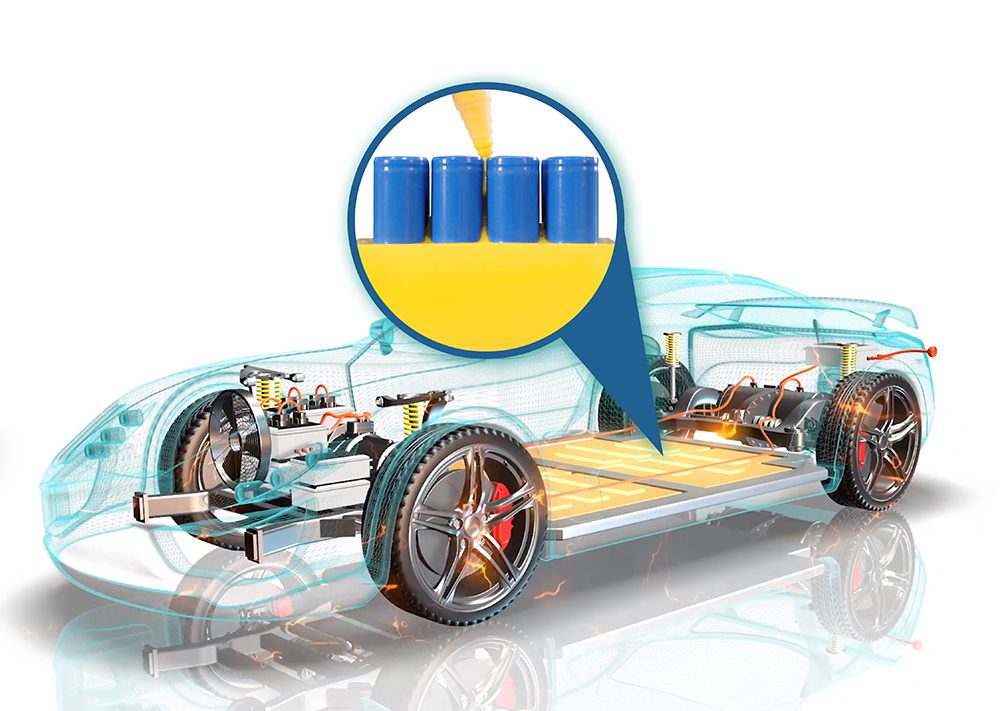

Finland-based Kalmar has introduced a second-generation lithium-ion battery system for its range of electrically powered counterbalanced equipment, including reach stackers, empty container handlers and forklifts.

The new battery system delivers enhanced energy capacity, improved thermal stability, and a longer, more predictable performance curve across a wide range of operating environments, according to the company. The technology is now available globally to meet the European standard, while versions for the US and Chinese standards will follow in 2026.

Building on the success of its previous Li-ion solution, Kalmar’s Gen 2 technology features a new cell chemistry that extends battery life cycle. Delivering more energy throughput than the previous generation, it provides consistent and reliable performance over the long term. This results in reduced battery replacement costs and easier shift planning, contributing to lower total cost of ownership.

Kalmar electric reach stackers will be able to operate for up to 10 hours in a heavy-duty application, allowing for greater flexibility and uptime in demanding terminal environments. The battery also offers improved thermal resilience for enhanced operational safety and stability, especially in hot climates.

“Our second-generation battery is a major step forward in helping our customers transition to fully electric fleets without compromising performance. The enhanced safety, longer lifespan and improved operating times provide a high level of predictability and peace of mind when it comes to managing their operations,” said Peter Berndtson, Vice President, Counterbalanced Product Line at Kalmar.

Source: Kalmar