Ionic Mineral Technologies, a US-based producer of nano-silicon battery anode technology, has announced the grand opening of its new production facility, technical center and headquarters in Provo, Utah.

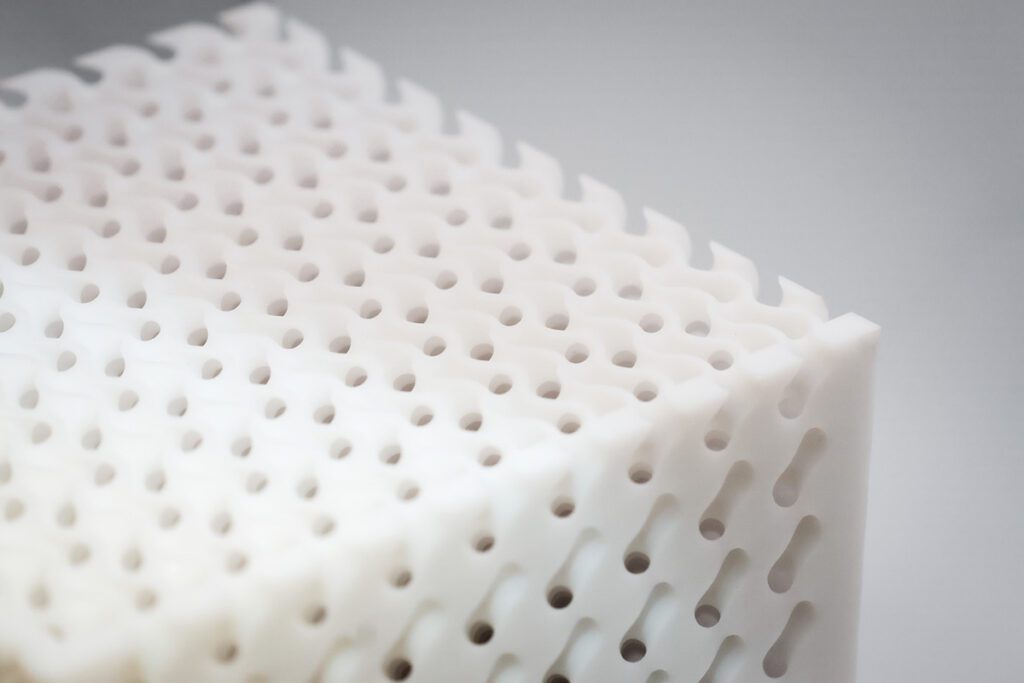

Ionic MT says the new facility will enable it to rapidly expand production of its Ionisil high-purity nano-silicon powder. Ionic says that, when incorporated as a 15% partial substitution for graphite, Ionisil can deliver a 100% increase in anode capacity. Ionisil also offers seamless compatibility with existing lithium-ion battery cell production lines.

Ionic MT uses a patented continuous production process that enables low-impact, high-capacity operations. The company also uses chemical recycling techniques to transform waste into value-added by-products, which it says results in a substantially reduced carbon footprint compared to conventional EV battery materials.

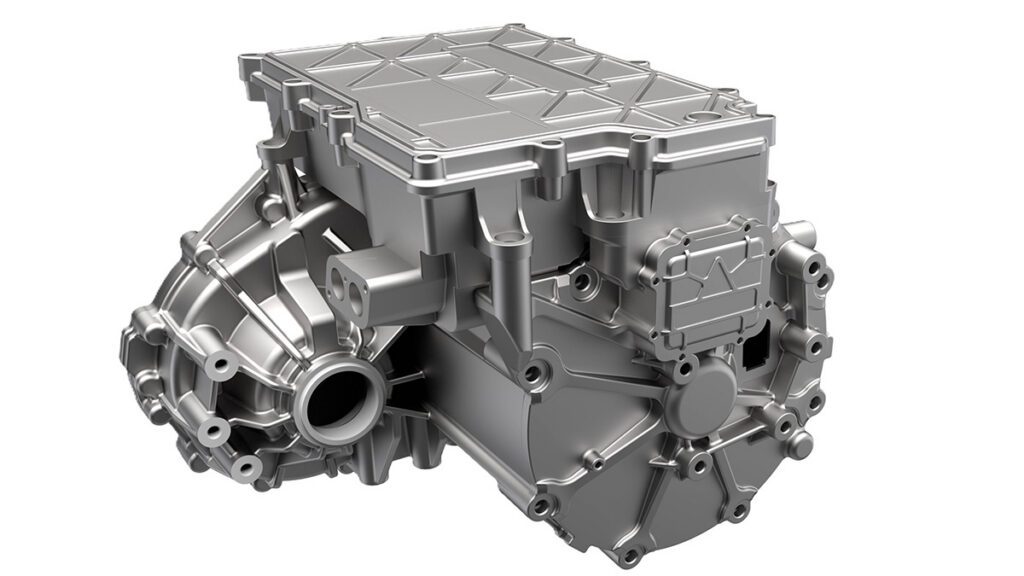

Commissioning of Ionic’s 37,000-square-foot facility is already underway. In Phase 1 of the development plan, the plant will be able to supply 2,000 tons of Ionisil per year—enough to energize approximately 300,000 EVs—by the second half of 2024. In Phase 2, the company will scale up to a total of 5,000 tons per annum (TPA) within the same building. Phase 3 involves collaborating with “a prominent global industrial partner” to engineer a greenfield production facility with an additional capacity of 20,000 TPA.

“At Ionic MT, we’re not just filling in a critical material supply gap; our Ionisil product technology is a material innovation that provides US EV manufacturers with a substantial competitive edge in addressing the requirements of high-performance, rapid-charging EVs at a more cost-effective rate,” said Andre Zeitoun, CEO and founder of Ionic MT.

Source: Ionic Mineral Technologies