EV Battery validation demands innovation in multiple dimensions but there is no playbook or best practices. EV engineers must figure out how to meet expectations of safety and operation, and testing a battery feels like hitting a moving target. There’s one variable that matters the most to accomplish these demanding goals: performance.

Join this webinar session at our Spring Virtual Conference on EV Engineering, presented by NI, where we will discuss how to increase the performance of:

- Engineering teams: to improve communication and data-driven decision making between design and test groups and roles

- Test lab and equipment: to maximize utilization, traceability of results, and repeatability of test, from one test cells to multi-cell facilities

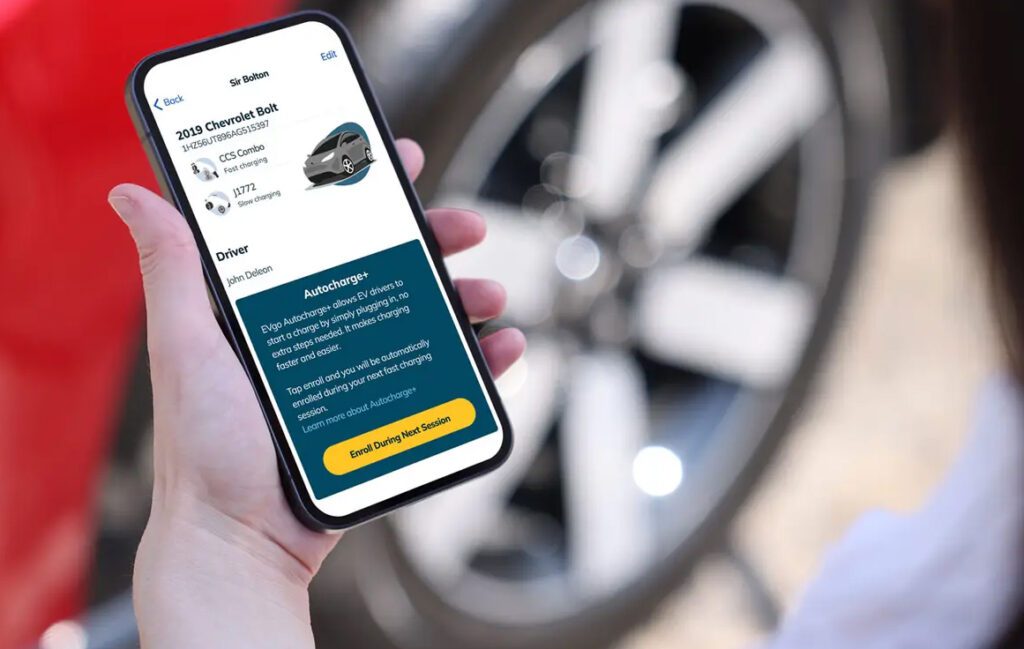

- Battery under test: to safely squeeze every mile out of the battery capacity and perform analytics to further improve the operation when deployed

Additionally, we’ll cover details on battery test software and analytics through demonstrations so that it’s clear how it is possible to hit the moving target, with uncompromising quality and safety.

Other sessions at our Spring Virtual Conference include:

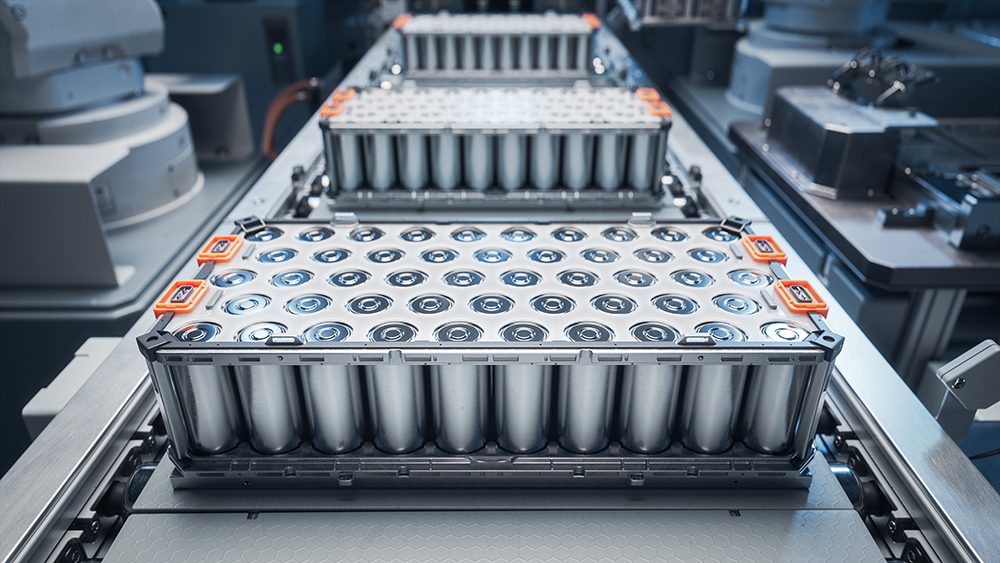

Mass Production Equipment For Li-ion Battery Products With Short Lifecycle Times

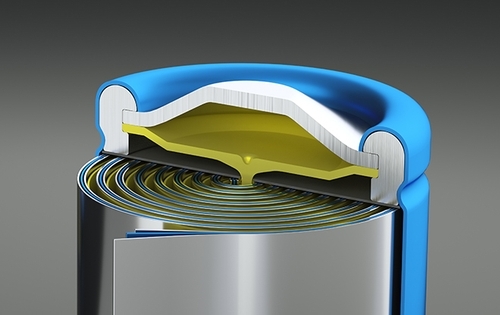

Whether power tools or stationary energy storage systems. The requirements on the battery modules are increasing rapidly and result in constantly changing module designs. One example of this is the variety of different cell designs. Yesterday cylindrical 18650 cells were used, today 21700 are common but what will happen tomorrow? Product life cycles are decreasing, but the modules have to be produced in high volumes.

Join this session to discuss how the result of these developments are big challenges for equipment manufacturers and forces them to develop modular, flexible and scalable solutions.

Register here to learn more—it’s free!

See the full sessions list for the Spring Virtual Conference on EV Engineering here.

Broadcast live April 4 – 7, 2022, the conference content will span the EV engineering supply chain and ecosystem including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.