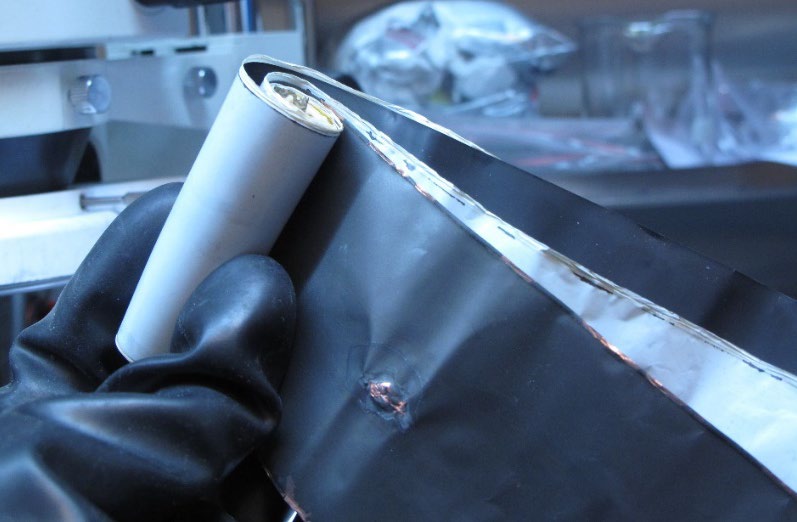

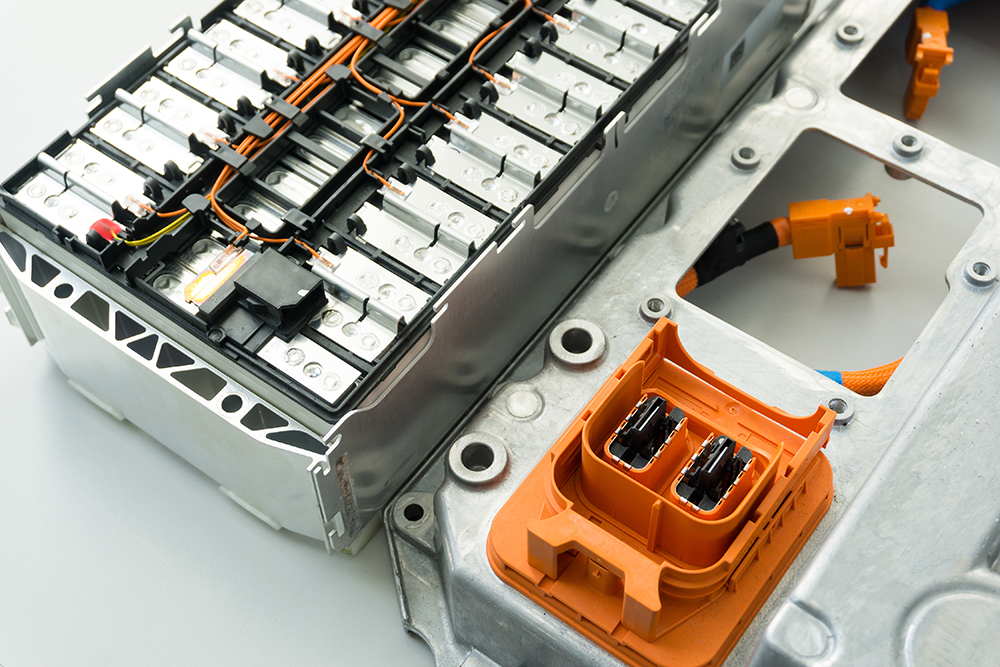

BASF is expanding its range of engineering plastics for electric and hybrid vehicles. Tailor-made Ultramid and Ultradur materials are now available for equipping vehicle-interior and -exterior high-voltage plug-in connectors with precisely fitting characteristics.

Plastics used for connectors in vehicles must meet stringent requirements regarding flame retardancy, color stability and electrical isolation. High-voltage connectors are typically orange in color, and that color needs to remain highly visible for at least ten years. BASF’s polyamide is color-stable and resistant to thermal aging.

BASF’s Ultramid and Ultradur grades conform to IEC standards 62196-1 and 60695-2-11, are resistant to high temperatures and coolants, and are designed for low warpage, impact strength and creep resistance.

“Components for battery-powered vehicles are evolving all the time, and each automotive manufacturer has special requirements,” says Wolfgang Balles of the Swiss firm TE Connectivity. “That is why for us, as a company that operates globally, it is vital to have a partner like BASF with which we can find the ideal combination of material and part. This is the only way that we can deliver safe and reliable components to the mass market,” adds TE’s Franz Janson.

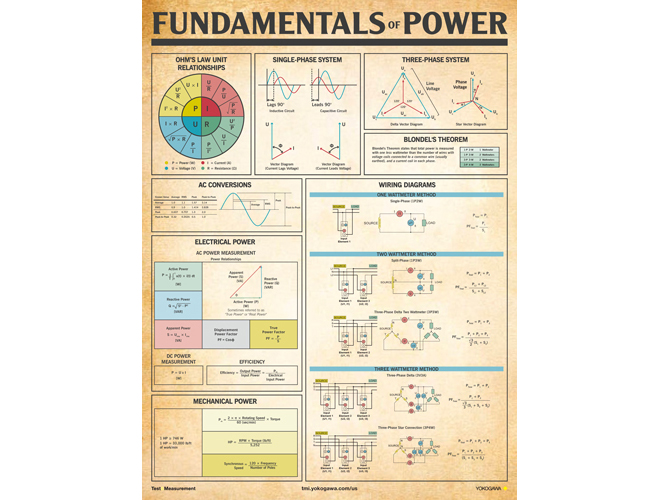

Source: BASF via Green Car Congress