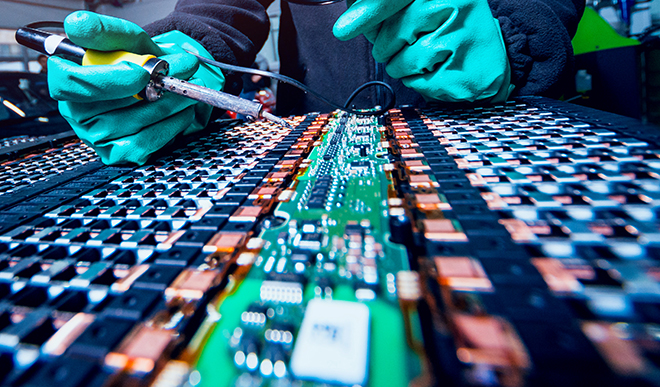

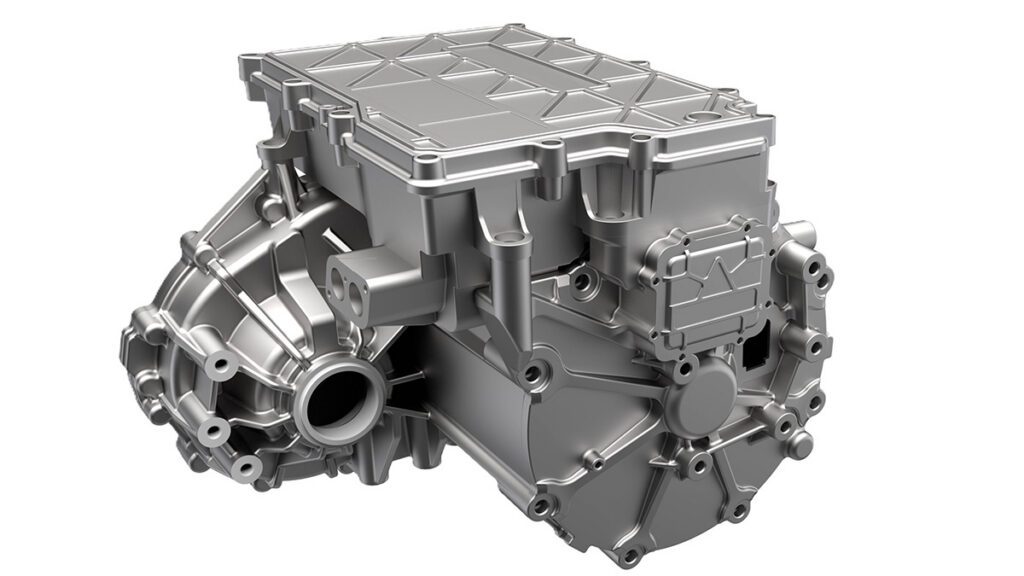

Circular economy and resource recovery specialists Axion, Aspire Engineering and Aceleron have launched an initiative to tackle the growing number of end-of-life EV batteries. They are currently providing a recovery service that begins with Aspire processing the batteries for remanufacturing, reuse and recycling. Next, Aceleron tests and repurposes the batteries. If the batteries cannot be reused, Axion will then collect them for recycling.

All three companies will leverage their specialized talents for the project. Axion was a part of the AMPLiFII (Automated Module-to-pack Pilot Line for Industrial Innovation) project, in which it developed techniques to recover metals from automotive battery packs. It is currently a partner in the CALIBRE project with several analysts and carmakers to demonstrate UK-based supply chains for spent batteries. Aspire took part in OEM R&D for battery systems and was a partner in the H1perbat consortium along with Williams Advanced Engineering and Aston Martin. Together with Aceleron, Aspire is a part of the remanufacturing research initiative VALUABLE, along with several universities. Using this combined experience, the companies intend to provide a profitable service based on the “Three Rs.”

“Combining the skills of all three companies opens up a more cost-effective end-of-life route by recovering batteries that still have a useful life, and extracts more value that can be passed on to clients,” says Axion Head of Engineering and Research Sam Haig. Aceleron CEO Amrit Chandan added, “Applying Aceleron’s battery testing and repurposing technology with Aspire’s remanufacturing knowledge and Axion’s ability to efficiently recycle really provides single-point-of-service value for battery users and vehicle OEMs across the UK.”

Source: Axion