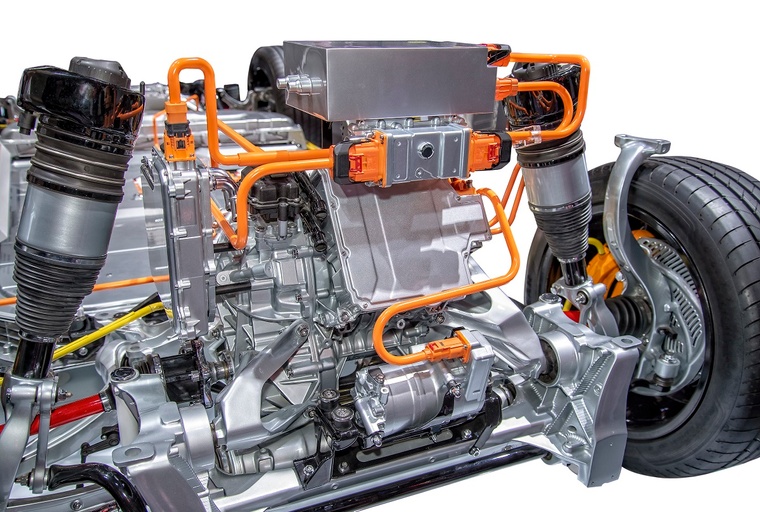

Predicting motor electromagnetics, noise, heat transfer, stresses, or simulating specific phenomena on an electric drive is technologically challenging and requires new fields of expertise and mindsets.

Join this webinar, at our Spring Virtual Conference on EV Engineering, where Sudhi Uppuluri and Benoit Magneville from Siemens explain how a collaborative and flexible ecosystem connects the toolsets and allows data to flow seamlessly. Illustrated with examples and demos, they will explain how to design, engineer and optimize each subsystem (motor, inverter, transmission), as well as the integrated system to reduce cost and maximize product performance, range, reliability and driving pleasure.

Key topics and takeaways:

- Deploy an integrated workflow for electric drive engineering

- Gain valuable insights into trading off attributes and developing the optimum design

- Rapidly re-design the electric drive and its components and reuse workflows

- Use the latest data version by staying connected to a PLM platform

Other sessions at our Spring Virtual Conference include:

Open Air Advantages And Applications Of Bidirectional DC Contactors

With the increased deployment of electric vehicles comes an increased demand for DC fast charging. What originally started with 400 V moved to 800 V and is now targeting 1200 V.

High voltages pose very specific challenges to the safety devices capable of reliably insulating and galvanically separating the DC power sources within a charging station from the vehicle or the on-board battery from the remaining vehicle network. Self-sustained arcing causing contacts to melt together is only one of many difficulties DC contactors must overcome.

Join this session, presented by Schaltbau, to learn about the open-air advantages and applications of bidirectional DC contactors.

Other sessions at our Spring Virtual Conference include:

Principals Of Thermal Management To Improve Battery Safety And Performance

Learn about the fundamentals of heat transfer and its impact on thermal management in a battery pack. Thermal management is critical in EV batteries to improve performance, safety, durability, and prevent battery fires. Next-generation battery designs can benefit from thermal interface materials and thermally conductive adhesives and coatings to help manage heat transfer.

Join this session to learn about H.B. Fuller’s innovative materials that will help achieve your thermal transfer goals.

See the full session list for the Spring Virtual Conference on EV Engineering here.

Broadcast live April 17 – 20, 2023, the conference content will span the EV engineering supply chain and ecosystem, including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.