Littelfuse helps the auto industry navigate new electrical engineering challenges

When engineers design a battery pack, they tend to focus first on its core functionality and value proposition. For a high-end energy storage device, those core attributes are typically things like total pack energy density, cost minimization, packaging efficiency, peak power and state-of-the-art thermal management.

It’s human nature to first narrow in on many of those design choices, and then, down the road, start to think more about compliance and circuit protection issues such as electromagnetic compatibility (EMC), electrostatic discharge (ESD), transient voltage and overcurrent protection requirements.

In the automotive world, where reliability and compliance requirements are very strict, many of these complex electrical engineering issues have recently become stumbling blocks for design teams. The fact is that this level of electrical expertise is practically brand-new in automotive – only about a decade old, as opposed to the various mechanical engineering specialties which have been around for a hundred years.

Jim Colby, Senior Business Development Manager at Littelfuse, has a front-row seat to the changing tide. Littelfuse has been providing circuit protection products to the automotive industry since the 1930s, and there is no one who can better describe the challenges of the transition to battery power.

“If we look at the bigger picture, we can see exactly what customers are challenged with as automotive changes from internal combustion cars to EVs,” Colby told Charged. “Everything is changing from mechanical/electrical-based systems to ones that are much more electronic in nature. So, the automakers’ internal expertise on the electrical side needs to expand to understand all the complex circuit protection concerns related to advanced electronic circuits and systems (microcontrollers, microprocessors, sensors, etc.). Our auto customers have a lot of questions about what to take into account, what kind of products can be used in different situations, for things like overcurrent, transient voltage and ESD. In some ways, now we’re acting a bit like a consulting business, which is similar to our normal sales process but now with more technical advice for automotive than for other industries.”

If you think about how a battery pack is similar to a gas tank, it helps to illustrate these new challenges. The pack brings in energy, stores it, then delivers it to the propulsion system. But because it’s electronic, it needs to be connected to the main processor so the vehicle’s brain can communicate with the pack. This means that problems that originate somewhere else can affect the pack, or vice versa.

Transient voltage

In vehicles, the leading communication architectures are the legacy systems CAN bus and LIN bus, which communicate with the main processor in the car.

“Every time you turn a motor on – like the windshield wiper or a window lift – there’s an inrush of current,” said Colby. “When you turn it off, you’re breaking an inductive load, so there’s a release of energy that shows up as transient voltages.”

These transient voltages could be tens of volts or hundreds of volts. It’s not a lot of energy, but it will show up in every single system of the car that’s connected to the power rail or the CAN bus and LIN bus communication lines. At the cell level, for example, you have sensor communication lines that connect each cell in a string to local processors that can control the cells. All the way down to that level, engineers need to design protection systems to be able to survive all the transient voltage events.

Additionally, in hybrid-electric vehicles, an event that is called “Load Dump” can occur if the battery leads from the alternator are broken, causing large amounts of energy to be dumped into the vehicle’s power system. This is another type of transient event that needs to be taken into account at the power input to the electronic modules that are found in a growing number of locations around the vehicle.

ESD

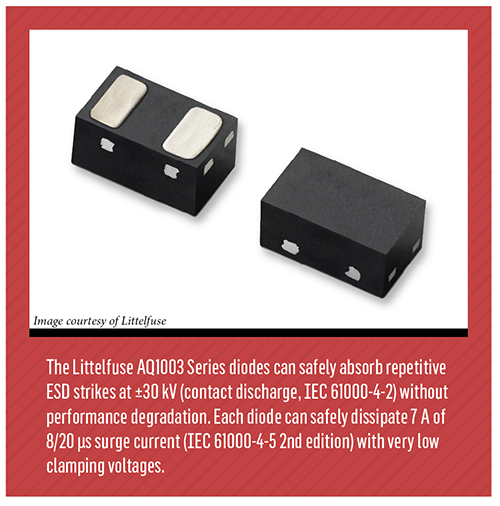

Static electricity has been known to cause problems at every stage of manufacturing and assembly. “If a factory is not well designed for mitigation of static electricity, you can see ESD problems on a circuit board when it’s first plugged in, well before it gets out of the manufacturing facility,” said Colby.

In addition to ESD damage during manufacturing, any systems that the vehicle’s passengers have access to, like USB ports, need to be protected from static electricity.

“Basically, what you’re trying to protect are the ICs,” explained Colby. “All of these chips will have some level of on-chip ESD protection, because they need to go to the wafer fabrication and then back into assembly, but usually it’s just for a few hundred volts. You need higher ESD protection in the field for things like the CAN bus transceiver, for example, to protect it from being damaged or destroyed. ESD will cause problems like oxide punch-through on the chip, or the actual traces in the IC that connect everything together can open up like a fuse. Then the chip is either immediately destroyed, or you have a walking wounded situation, with a shorter lifetime than usual.”

Obviously, this is a huge concern for the OEMs, because CAN bus and LIN bus are considered part of the core safety architecture of any vehicle, whether it’s electric or ICE-powered. So much so that automakers will essentially mandate that there’s ESD protection on both of those buses.

Colby explained that this protection is typically provided by a single small device. “CAN bus is a two-wire system, for example, so we have a SOT-23 3-lead device that connects to both lines and a reference ground nearby to shunt any ESD through the device to ground.”

Overcurrent

Modern automotive battery packs contain anywhere from a few hundred to a few thousand individual cells. If there is an accident and the battery pack gets deformed or punctured, there could be the opportunity for a low-voltage line connecting a string of cells to come in contact with the high-voltage line that’s nearby. So the cells need to be disconnected as soon as possible, which typically means that every single one of those lines is protected by a fuse.

Also, the main pack itself has to have some way to disconnect, so there are typically high-voltage, high-current fuses – as well as a high-voltage TVS diode to protect the entire pack against transient voltages, Colby explained.

Change is the only constant

As the market for EVs develops, battery capacities continue to grow. Therefore, charging levels are increasing as well, so that charging times can be decreased and driving distances increased.

To that end, many automakers have indicated an inevitable switch from battery packs operating at about 450 volts to 800 volts and above. We can see the effects rippling out to the electronics – for example, there is a flurry of activity around silicon carbide products (another EV technology that Littelfuse has been heavily investing in). One of the reasons many are looking to switch from standard silicon IGBT modules to silicon carbide is that the latter is more optimized for high voltage – it can switch more quickly, and it’s a more efficient power conversion device.

In terms of circuit protection, higher-voltage packs mean that all the R&D that Littelfuse and others have been doing to produce new automotive-grade protection products will surely continue. Because of the strict reliability requirements of the automakers, developing some of these relatively simple devices has been a ground-up endeavor.

“If you look at a transient-voltage-suppression (TVS) diode, for example, it’s a fairly straightforward PN-junction device that goes in the DC circuits,” said Colby. “Billions per year are manufactured that are commercial-grade. But to bring that into the automotive-grade world, we had to start from the ground up. While the design is fairly simple – a copper lead frame, the die itself, the leads and then the molding compound – literally every single one of those components had to be redesigned for us to meet automotive standards. So in our factory we actually have one set of production lines for the commercial-grade TVS diodes and another set of lines to produce automotive-grade units that include more automation and tighter reliability concerns.”

“The transition from the era of internal combustion vehicles to the developing e-mobility will bring with it design challenges at all levels – from the core powertrain and energy storage systems to the components that support and protect them,” continued Colby. “It is an exciting time to be involved in this evolving market. Companies like Littelfuse will continue to provide improved protection and power control products to the OEM and Tier 1 companies as they look to bring out more-efficient vehicles that meet the demanding reliability requirements that have been set over the previous hundred-plus years.”

This article originally appeared in Charged Issue 37 – May/June 2018 – Subscribe now.