Charged Electric Vehicles Magazine

Issue 37 – May/June 2018

Featuring

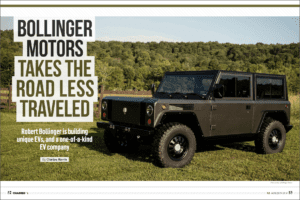

Robert Bollinger is building unique EVs, and a one-of-a-kind EV company

Bollinger Motors is not following the typical EV startup formula. Instead of building a luxury sedan, it’s building a rough and ready work truck. It has no strategy to evolve into a mass-market automaker, but intends to find a niche as a low-volume brand. As far as we know, the company has no former Tesla… Read more »

Top circuit protection requirements to consider when designing an automotive battery pack

Littelfuse helps the auto industry navigate new electrical engineering challenges When engineers design a battery pack, they tend to focus first on its core functionality and value proposition. For a high-end energy storage device, those core attributes are typically things like total pack energy density, cost minimization, packaging efficiency, peak power and state-of-the-art thermal management…. Read more »

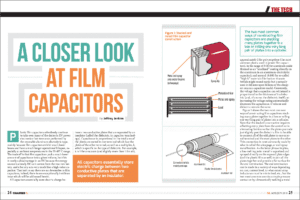

A closer look at film capacitors

Plastic film capacitors relentlessly continue to take over many of the duties in EV power electronics that were once performed by the venerable aluminum electrolytic type, mainly because film capacitors exhibit much lower losses and have a much longer operational lifespan, especially at ambient temperatures in the 75-85° C range. The tradeoff is that film… Read more »

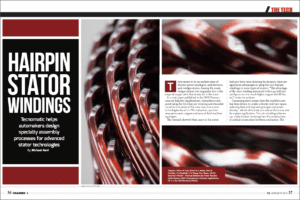

Tecnomatic helps automakers design specialty assembly processes for advanced stator technologies

There seems to be an endless array of electric motor topologies, architectures, and configurations. Among the many design choices that engineers face is the shape of copper wire that is wound in the stator. In a new paper published in the IEEE Transactions on Industry Applications, researchers compared using flat wire hairpin winding and stranded… Read more »

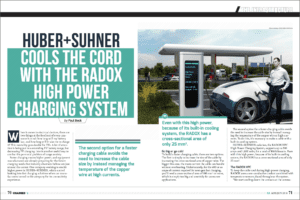

Huber+Suhner cools the cord with the RADOX high power EV charging system

When it comes to electrical devices, there are two things at the forefront of every consumer’s mind: how long will my battery last, and how long will it take me to charge it? This mentality goes double for EVs. A lot of attention is being put into extending EV battery range, but decreasing EV charging… Read more »

US energy regulators issue a new storage rule with important implications for EVs

In March, the Federal Energy Regulatory Commission (FERC) issued a rule requiring regional electrical grid operators to revise their regulations pertaining to energy storage and how storage resources might participate in electricity markets. Okay, it sounds a bit wonky, but FERC’s decision is an important policy shift that could have a big impact on EVs…. Read more »